A kind of high flame retardant felt for automobile engine compartment and its manufacturing method

An engine compartment, high flame-retardant technology, applied in textiles and papermaking, fiber treatment, non-woven fabrics, etc., to achieve the effects of weight reduction, elastic sound absorption performance, and material weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

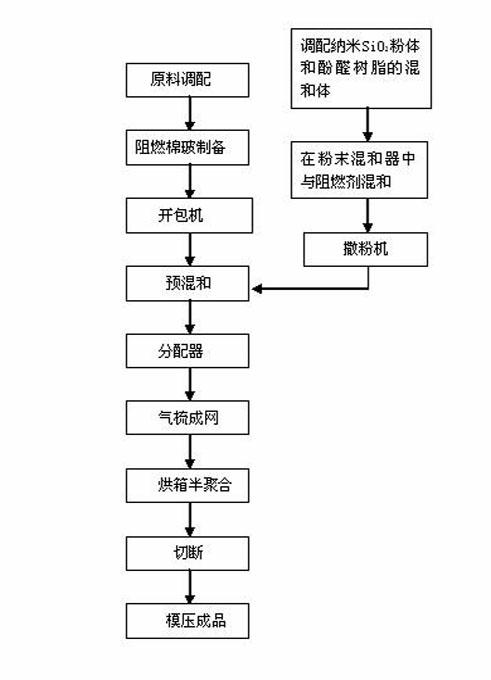

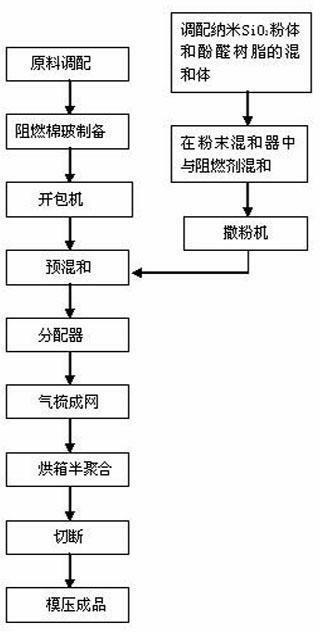

Method used

Image

Examples

Embodiment 1

[0034] First prepare the powdered ammonium polyphosphate flame retardant and water into an aqueous solution with a concentration of 30%, and evenly spray the aqueous solution on 35.8kg of open cotton to make the open cotton sufficiently moist, cover it well and place it for 24 hours before Let it dry completely in the natural state and open evenly. When opening, add 8.2 kg of recycled glass fiber with a length of 20mm to prepare a mixture of recycled glass fiber and flame-retardant opening cotton.

[0035] Then, 0.78㎏ nano-SiO 2 The powder is mixed with 41.2kg of phenolic resin through special equipment to make nano-SiO 2 The powder is evenly dispersed into the phenolic resin material and formulated into nano-SiO 2 The mixture of powder and phenolic resin is placed in a powder mixer, and then 13 kg of ammonium polyphosphate flame retardant is added and mixed evenly.

[0036] Finally, the mixture of recycled glass fiber and flame-retardant opening cotton is put into the bale...

Embodiment 2

[0038] First prepare the powdered ammonium polyphosphate flame retardant and water into an aqueous solution with a concentration of 32%, and evenly spray the aqueous solution on 76.8 kg of opening cotton to make the opening cotton sufficiently moist. Let it dry completely in the natural state and open evenly. When opening, 19.2 kg of recycled glass fiber with a length of 40mm is added to prepare a mixture of recycled glass fiber and flame-retardant opening cotton.

[0039] Then, 1.46kg of nano-SiO 2 The powder is mixed with 76.54kg of phenolic resin through special equipment to make nano-SiO 2 The powder is evenly dispersed into the phenolic resin material and formulated into nano-SiO 2 The mixture of powder and phenolic resin is placed in a powder mixer, and then 26 kg of ammonium polyphosphate flame retardant is added and mixed evenly.

[0040] Finally, the mixture of recycled glass fiber and flame-retardant opening cotton is put into the bale opener, and the flame retard...

Embodiment 3

[0042] First prepare the powdered ammonium polyphosphate flame retardant and water into an aqueous solution with a concentration of 35%, and evenly spray the aqueous solution on 32.6kg of opening cotton to make the opening cotton sufficiently moist, cover it well and place it for 24 hours before Let it dry completely in the natural state and open evenly. When opening, add 9.8 kg of recycled glass fiber with a length of 60mm to prepare a mixture of recycled glass fiber and flame-retardant opening cotton.

[0043] Then, 0.82㎏ nano-SiO 2 The powder is mixed with 40.18kg of phenolic resin through special equipment to make nano-SiO 2 The powder is evenly dispersed into the phenolic resin material and formulated into nano-SiO 2 The mixture of powder and phenolic resin is placed in a powder mixer, and then 14 kg of ammonium polyphosphate flame retardant is added and mixed evenly.

[0044] Finally, the mixture of recycled glass fiber and flame-retardant opening cotton is put into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com