Super-hydrophobic material and preparation method thereof

A technology of super-hydrophobic and expanded microspheres, which is applied in the field of preparation of low-density super-hydrophobic materials, can solve the problems of complex production process, loss of hydrophobic properties, and easy detachment of super-hydrophobic surface layers, so as to simplify the process flow, improve hydrophobic properties, Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

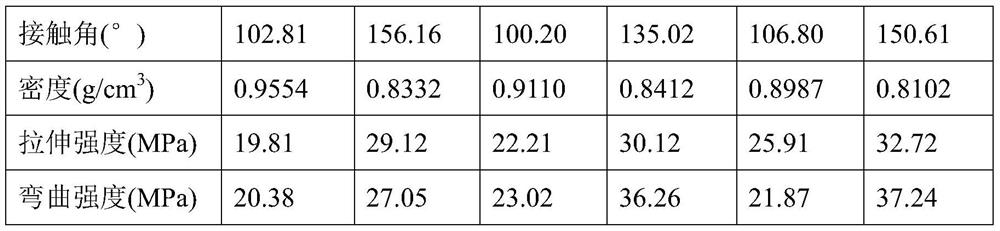

Embodiment 1

[0030] The preparation method of superhydrophobic HDPE material comprises the following steps:

[0031] Step 1: Premix the expandable microspheres DU260 and EVA in a mixer at a mass ratio of 1:1 for 20 minutes.

[0032] The second step: adding 4wt% EBS wax to the pre-mixed material and mixing, then adding it to a single-screw extruder, and extruding and granulating at 80°C to obtain functional masterbatch.

[0033] The third step: adding 4 wt % of the above functional masterbatch to the HDPE plastic resin, and carrying out an injection molding experiment in an injection molding machine to obtain a 5 mm dumbbell-shaped injection molded part.

Embodiment 2

[0037] The preparation method of superhydrophobic LDPE material comprises the following steps:

[0038] The first step: premix the expandable microspheres DU608 and EVA in a mixer for 20min according to the mass ratio of 1:1.

[0039] The second step: adding 4wt% EBS wax to the pre-mixed material and mixing, then adding it to a single-screw extruder, and extruding and granulating at 80°C to obtain functional masterbatch.

[0040] The third step: adding 4 wt % of the above functional masterbatch to the LDPE plastic resin, and carrying out an injection molding experiment in an injection molding machine to obtain a 5 mm dumbbell-shaped injection molded part.

Embodiment 3

[0044] The preparation method of superhydrophobic PP material comprises the following steps:

[0045] Step 1: Premix the expandable microspheres DU180 and EVA in a mixer at a mass ratio of 1:1 for 20 minutes.

[0046] The second step: adding 4wt% EBS wax to the pre-mixed material and mixing, then adding it to a single-screw extruder, and extruding and granulating at 80°C to obtain functional masterbatch.

[0047] The third step: adding 4 wt % of the above functional masterbatch to the PP plastic resin, and carrying out an injection molding experiment in an injection molding machine to obtain a 5 mm dumbbell-shaped injection molded part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com