Sewing machine thread regulator controlled by solenoid valve

An adjustment device and sewing machine technology, applied in the direction of sewing machine components, tension devices, sewing equipment, etc., can solve the problems of incorrect control of thread tension, difficulties, etc., and achieve the effect of easy tension adjustment, rapid tension change, and small stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

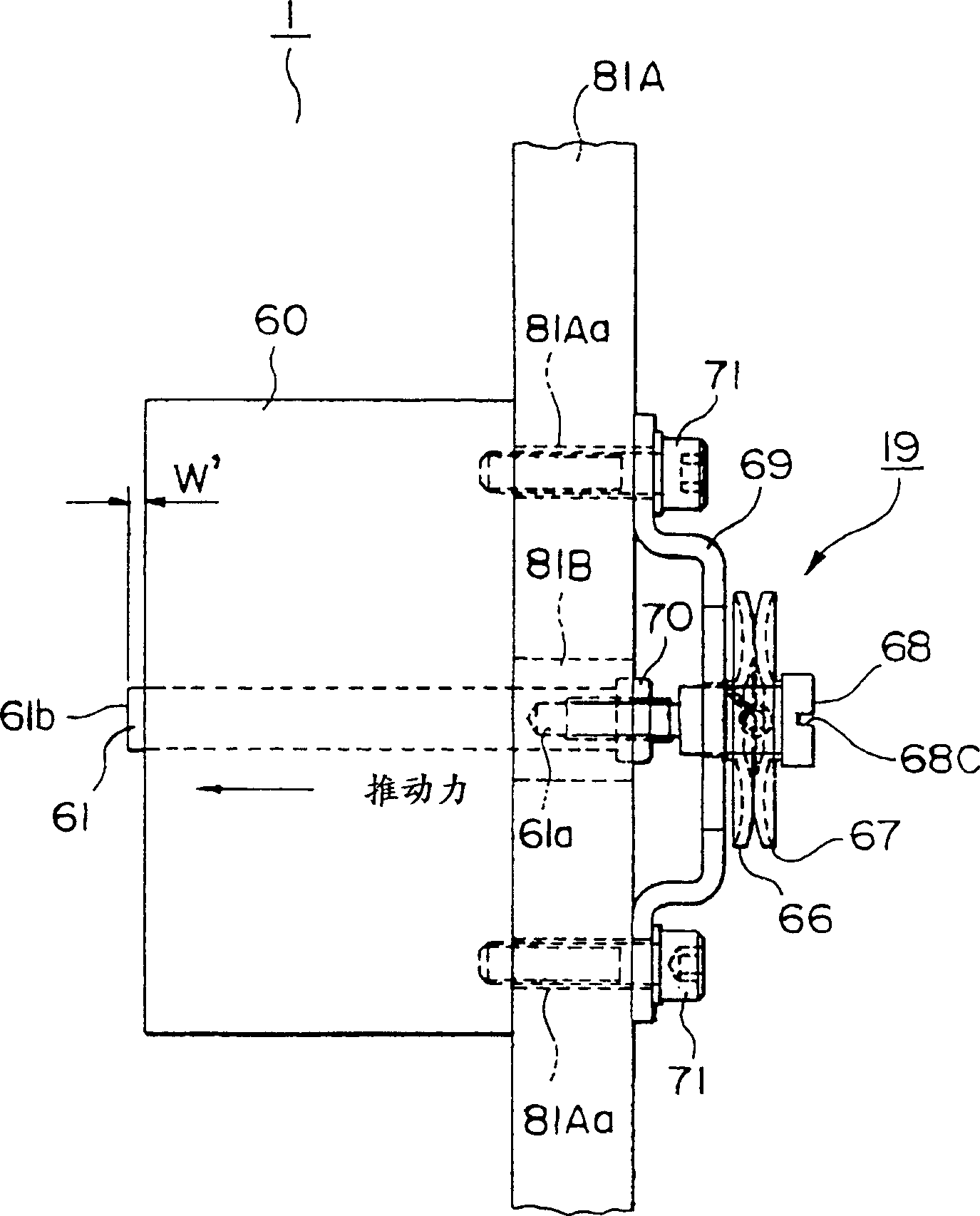

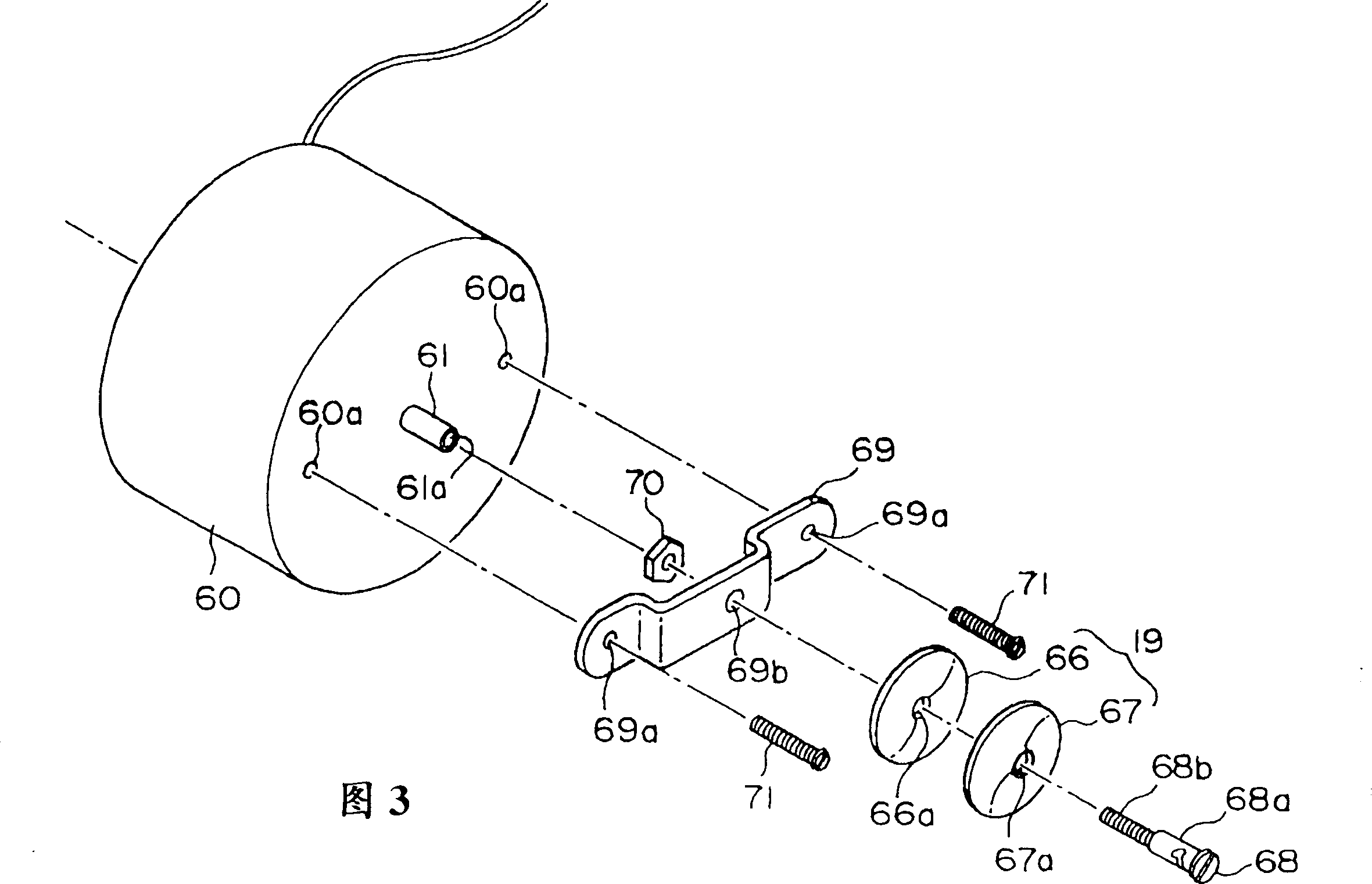

[0033] Embodiments of the present invention will be described below with reference to the drawings.

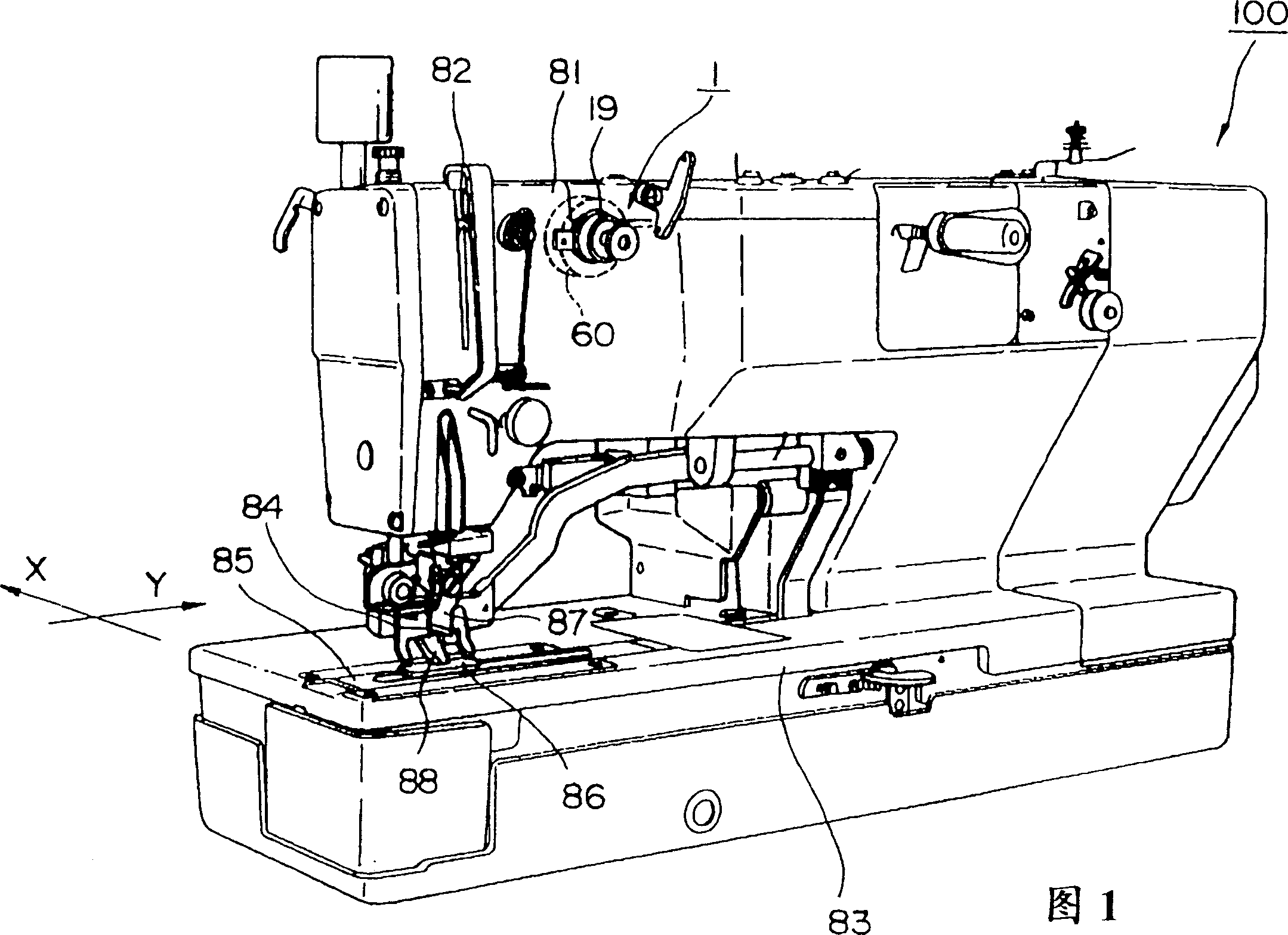

[0034] As shown in FIG. 1 , the thread adjusting device 1 of this embodiment is provided on the frame portion 81 of the sewing machine 100, and is a device for supplying tension to the upper thread from the cantilever 82 on the upper thread supply source side. This sewing machine 100 is an industrial buttonhole lockstitch sewing machine for forming buttonhole lockstitches. Figure 9 Buttonhole escutcheon 90 shown. The button hole keyhole 90 is mainly composed of side seams 92, 92 arranged on the left and right sides of the button hole groove 91, and upper and lower reinforcement seams 93, 93 as stoppers. Clamp the cloth M with the slide plate 85 and the cloth press 86 and control it to be sent to the Y direction, and at the same time, the pin 84 is swung to the X direction by the pin pendulum mechanism (not shown) provided in the sewing machine support part 81 to form the key...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com