Marble type railway lamp

A marble-type, track-based technology, applied in the field of track lights, can solve problems such as laborious movement, easy jamming, time-consuming and labor-intensive problems, and achieve the effect of solving tolerances, large currents, and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

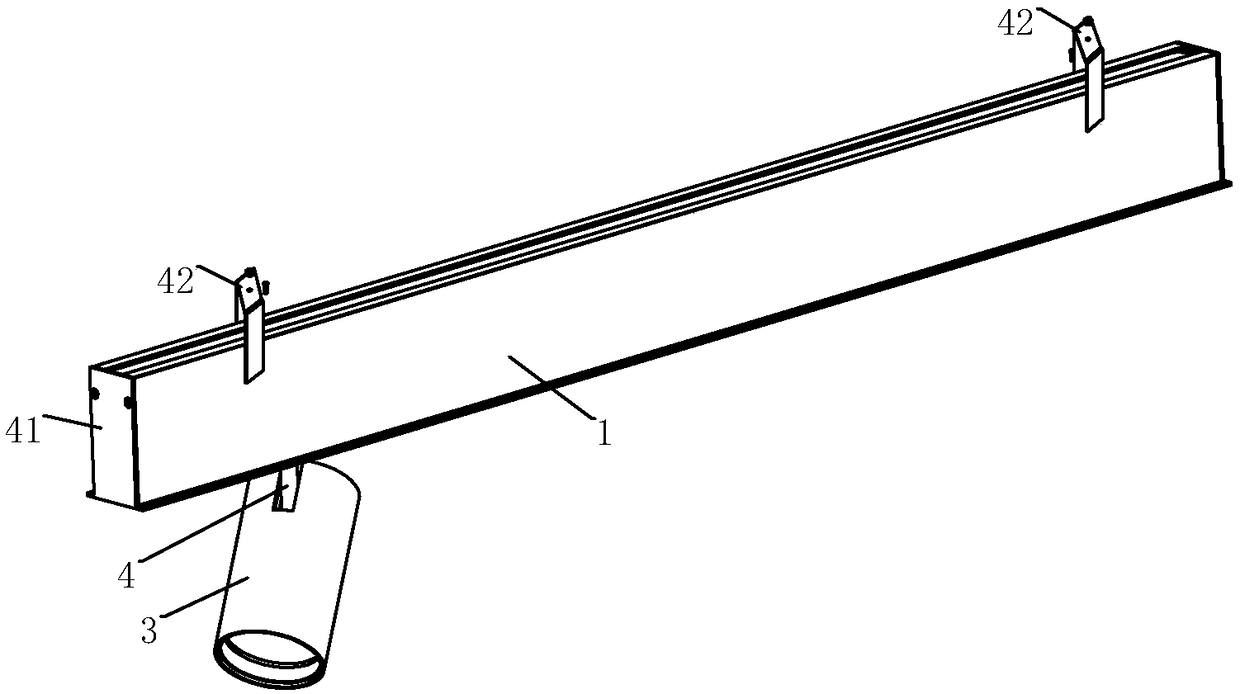

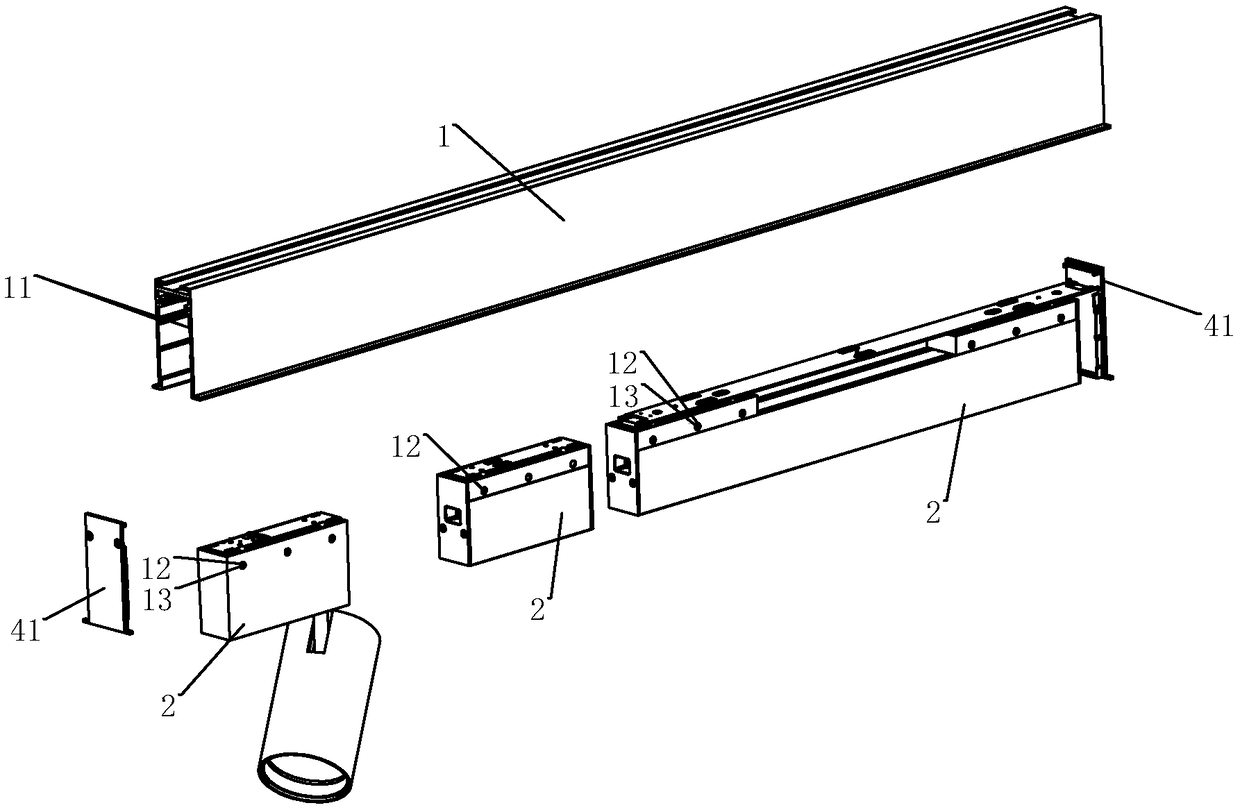

[0022] Such as Figure 1-Figure 2 As shown, it is a pinball-type track lamp of the present invention, which includes a track groove 1 and at least one lamp body 2 slidably arranged in the track groove 1. Third plugs 41 are arranged on both sides of the track groove 1, and the track The top of the tank 1 is connected with a fixed bracket 42 by bolts.

[0023] The two opposite inner walls of the track groove 1 are provided with opposite ball grooves 11, and the ball grooves 11 are in the same sliding direction as the lamp body 2;

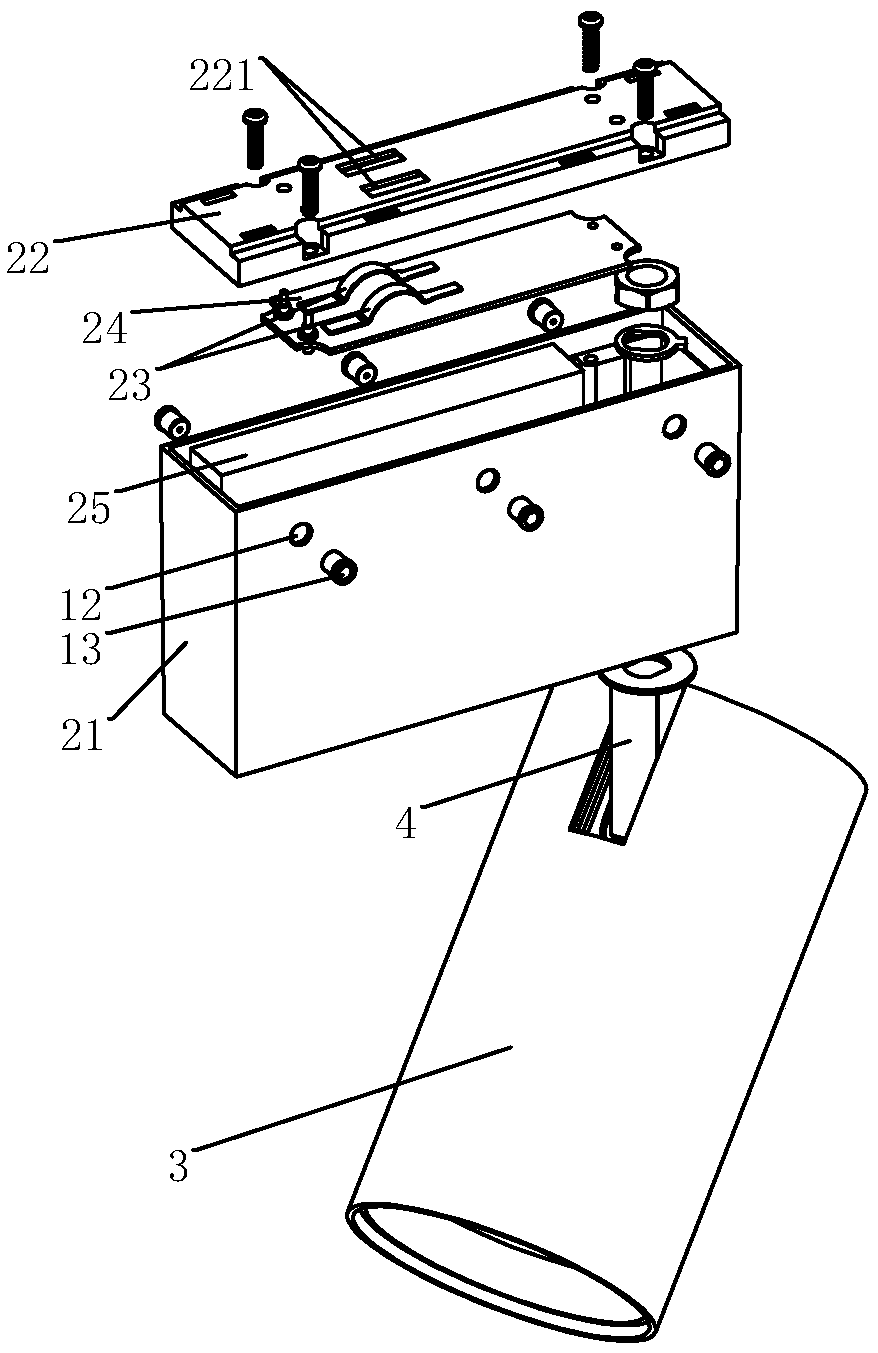

[0024] The two side walls of the lamp body 2 in contact with the track groove 1 are respectively provided with a plurality of mounting holes 12, and the mounting holes 12 are connected with balls 13 through elastic members, and the balls 13 leak outside the mounting holes 12 and are connected with the balls. Groove 11 is a rolling fit. The elastic member may be a spring, a shrapnel or other known elastic members.

[0025] Its working mechanism is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com