Non-aqueous electrolyte secondary battery

a secondary battery, non-aqueous electrolyte technology, applied in the direction of active material electrodes, non-aqueous electrolyte accumulator electrodes, cell components, etc., can solve the problems of cycle performance deterioration, and achieve the effect of reducing the expansion/contraction of silicon during charge/discharge and improving cycle performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment a

Embodiment A1

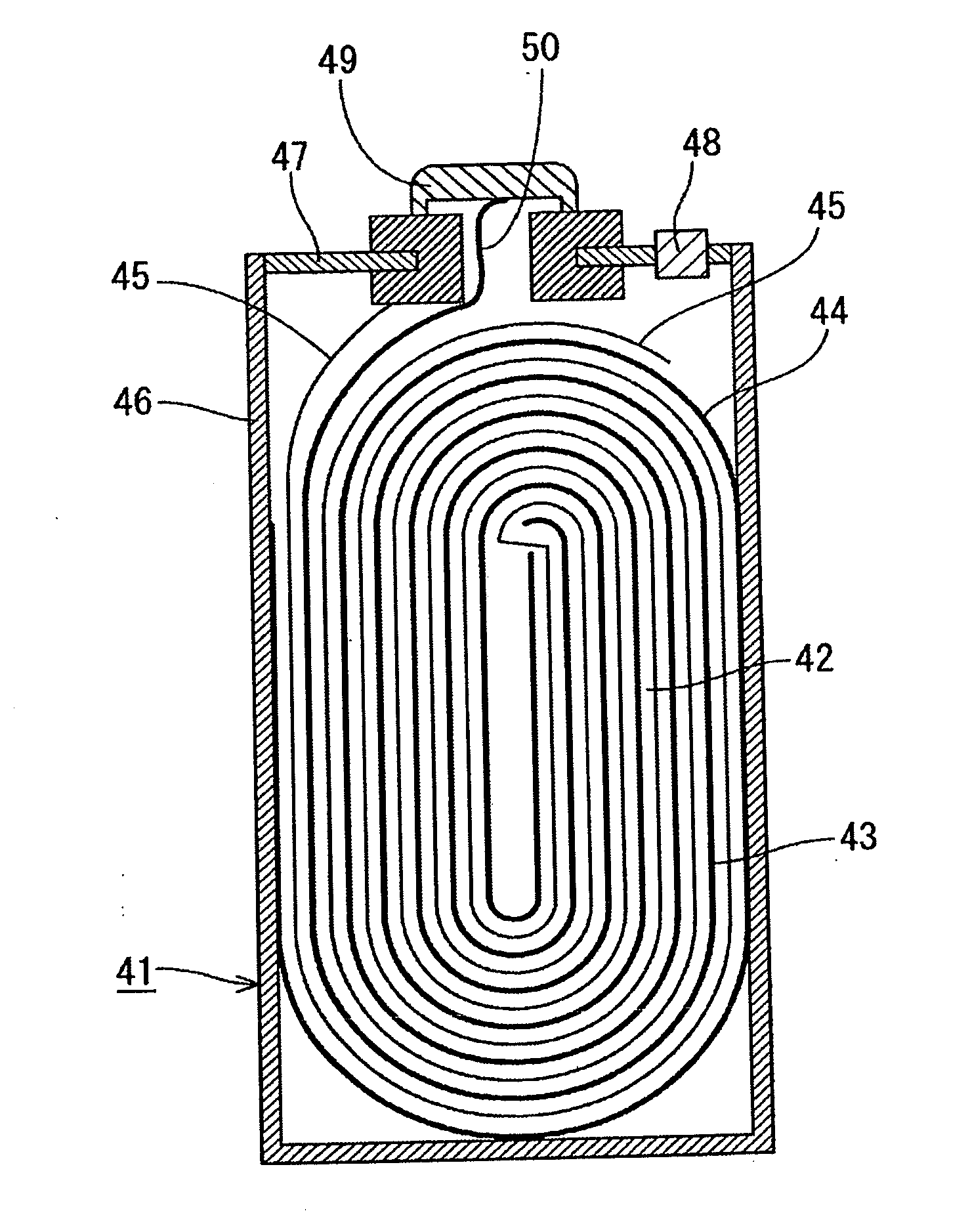

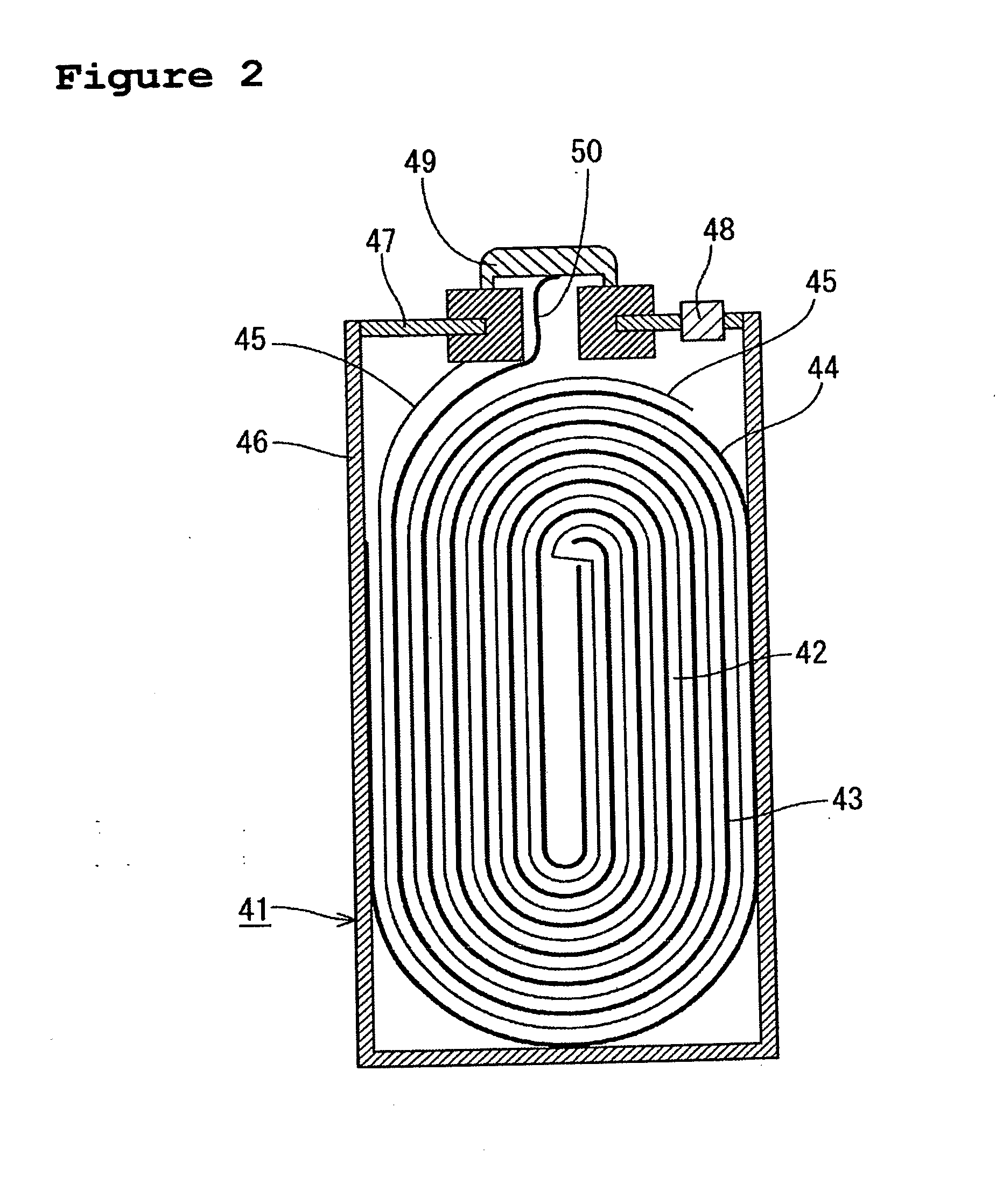

[0084]Lithium cobalt oxide was used as a positive active material in the preparation of a non-aqueous electrolyte secondary battery of a prismatic type. FIG. 2 shows the cross sectional configuration of a non-aqueous electrolyte secondary battery of a prismatic type. In FIG. 2, the non-aqueous electrolyte secondary battery of a prismatic type is expressed as 41, winding-type electrodes as 42, an positive electrode as 43, a negative electrode as 44, a separator as 45, a battery case as 46, a battery cap as 47, a safety valve as 48, a positive terminal as 49, and a positive lead as 50.

[0085]The winding-type electrodes 42 is housed in the battery case 46, the battery case 46 is equipped with the safety valve 48, and the battery cap 47 and the battery case 46 are sealed up by means of laser welding. The positive terminal 49 is connected with the positive electrode 43 with the positive lead 50, and the negative electrode 44 is connected to the inner wall of the battery case ...

embodiments a2 to a5

, and Comparative Example A1

[0091]In these batteries, the following weight percentages were used as the amount of carbon coating in the composite particle (C): 0, 5, 40, 60, and 70 wt. %. Except for the above, the batteries have an identical configuration to that of Embodiment A1.

[0092]These non-aqueous electrolyte secondary batteries were charged at a constant current of 1 CmA and a constant voltage of 3.9 V at a temperature of 25° C. for 3 hours and made to reach a fully charged state. Subsequently, they were discharged at a current of 1 CmA until the voltages dropped to 2.45 V. These steps were taken as one cycle and the obtained discharge capacity was considered as the initial discharge capacity. After that, under the same conditions as the above, a total of 100 charge / discharge cycles were carried out, and the discharge capacity at the 1st cycle and a change in discharge capacity with an increase in the number of cycle times (capacity retention ratio according to cycle) were de...

embodiments a10 to a14

[0098]In these batteries, the following areas were used as the BET specific surface area of the composite particle (C): 1.0 m2 / g, 6.3 m2 / g, 10 m2 / g, 0.5 m2 / g, and 11.0 m2 / g. Except for the above, the batteries have an identical configuration to that of Embodiment A1.

[0099]In the same manner as the above, the discharge capacity at the 1st cycle and a change in discharge capacity with an increase in the number of cycle times (capacity retention ratio according to cycle) were determined. The results are shown in Table A3.

TABLE A3BET specificCapacity retentionDischargesurface arearatio accordingcapacity(m2 / g)to cycle (%)(mAh)EM A17.490640EM A101.085635EM A116.381638EM A1210.084620EM A130.562630EM A1411.079590

[0100]These results reveal that when the BET specific surface area of the composite particle (C) falls within the range of 1.0 to 10.0 m2 / g, satisfactory cycle performance is achieved. It is believed that when the BET specific surface area is less than 1.0 m2 / g, the current density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature rising | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com