Pipe connector and manufacture method thereof

A technology for pipe joints and casings, applied in the field of pipe joints and their preparation, can solve the problems of high cost and large thickness of pipe joints, and achieve the effects of reducing wall thickness, material weight and material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

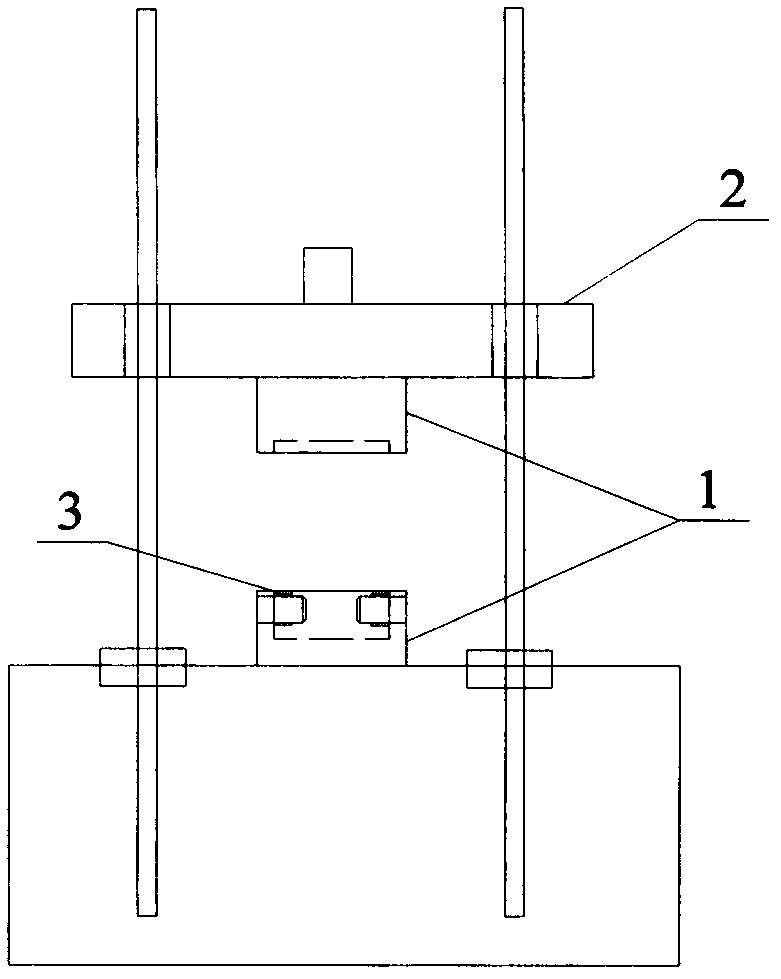

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] FRP is the abbreviation of Fiber Reinforced polymer (fiber reinforced material).

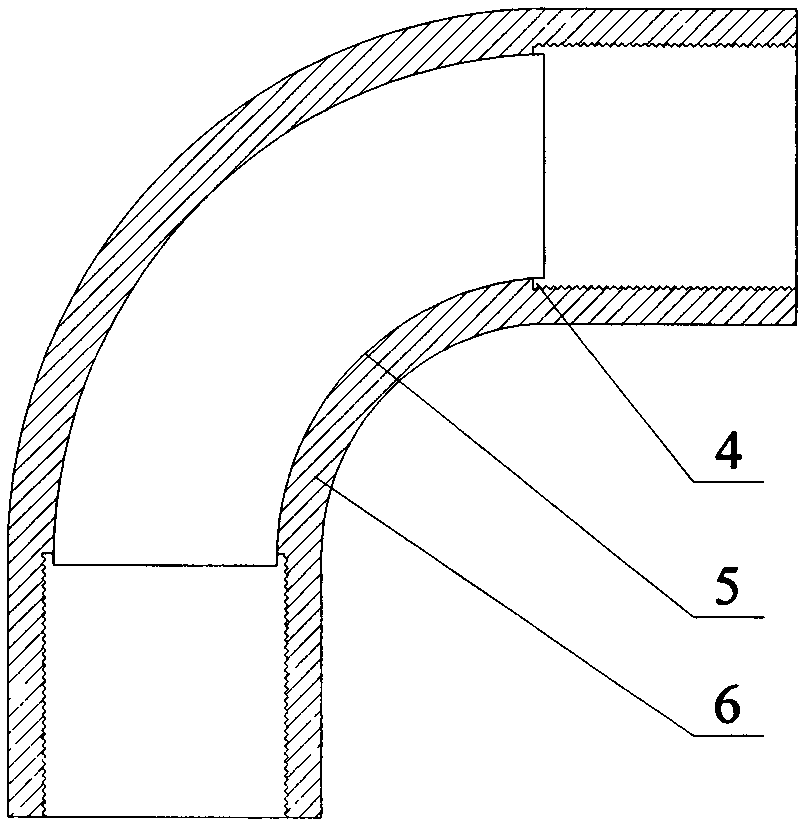

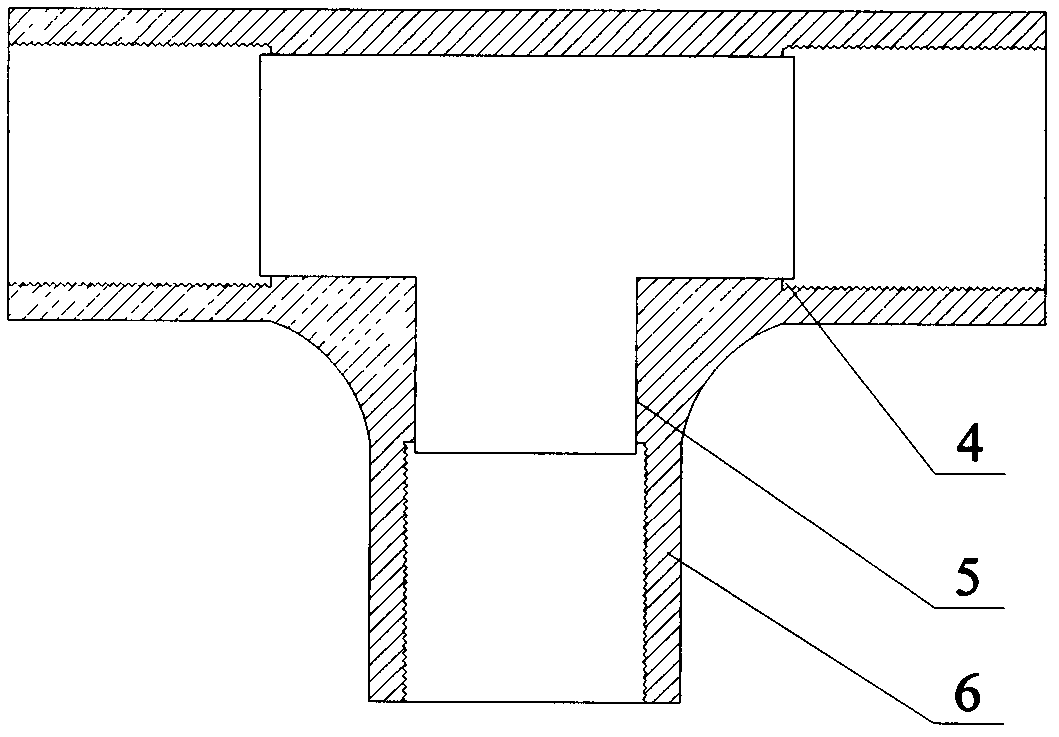

[0027] like Figure 2 to Figure 3 As shown, the present invention provides a pipe joint, which includes a sleeve 5 and an FRP material 6 fastened on the outer surface of the sleeve 5 . Under the condition of ensuring various performance indexes of the pipe joint, the wall thickness of the casing 5 is effectively reduced, material cost and material weight are reduced; and the use of the FRP material 6 meets the development needs of a green, environment-friendly and resource-saving society. In the pipe joint produced by the present invention, the FRP material 6 is smooth so that the pipes can be connected through the insertion method, which well solves the limitation of the application of the pipes.

[0028] The FRP material 6 includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com