Method for enhancing bearing capacity of composite foundation and rigid pile thereof

A load-bearing capacity and reinforced composite technology, which is applied in the direction of sheet pile walls, soil protection, and foundation structure engineering, can solve the problems of high cost and insufficient bearing capacity, and achieve low manufacturing cost, convenient manufacturing, installation and use, and improved Effects on bearing capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

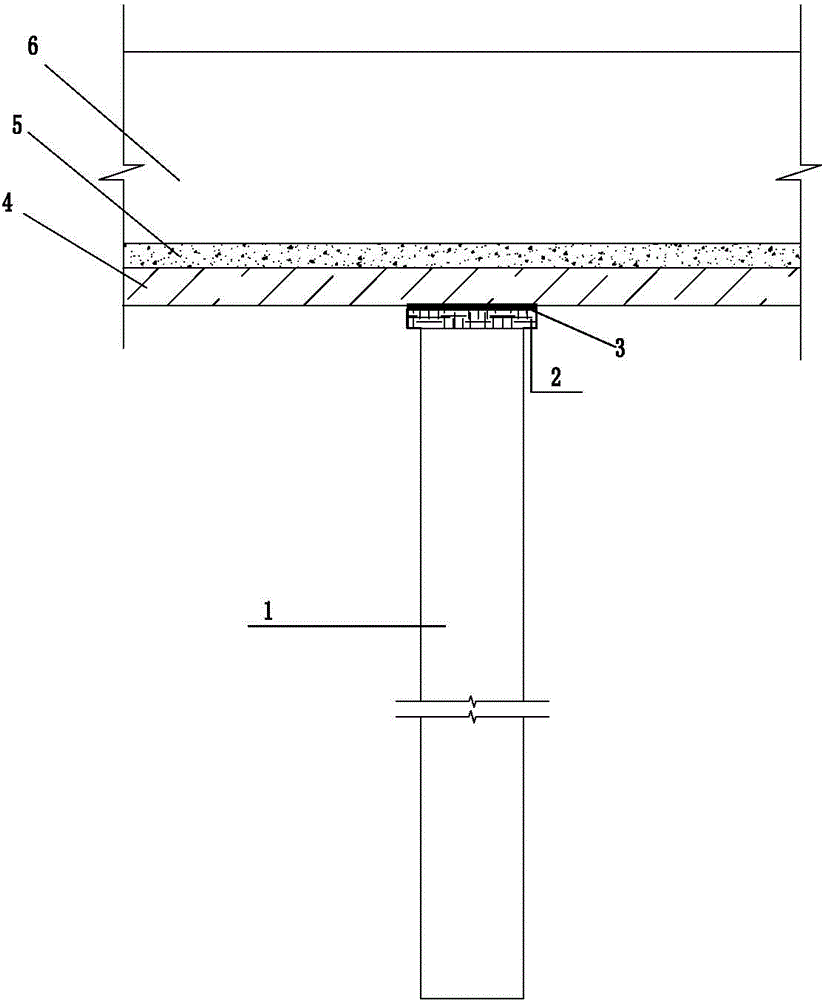

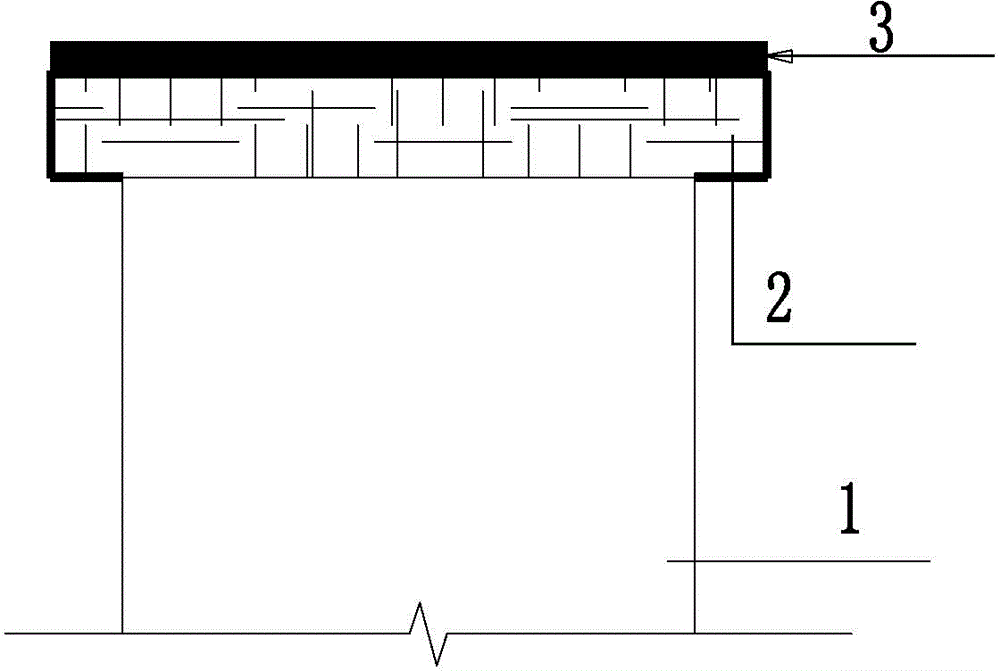

[0024] Such as Figure 1-2 shown.

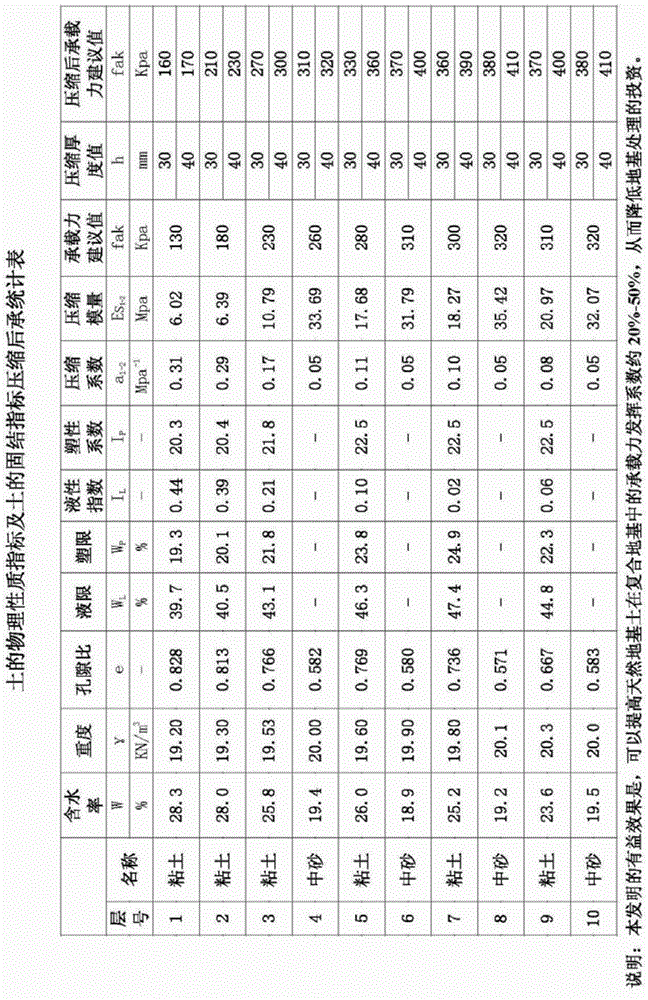

[0025] A method for enhancing the bearing capacity of a composite foundation, which uses a pile cap 2 capable of compressive deformation and whose compression modulus is equivalent to that of the foundation soil (structure such as figure 2 As shown), the load of the superstructure of the composite foundation is transferred to the natural foundation soil layer first through the coordination of the foundation and cushion layer, so that the natural foundation soil layer can sink by the amount of compressible deformation of the pile cap, thereby improving the natural foundation soil The bearing capacity is 20-50%, and at the same time, the rigid pile produces a penetrating action during the foundation settlement process to improve the bearing capacity and stability of the rigid pile. Such as figure 1 shown. The compressive modulus of described pile cap is suitable with foundation soil, and its profile matches with rigid pile end face (can be...

Embodiment 2

[0031] Such as Figure 1-2 shown.

[0032] A rigid pile used to enhance the bearing capacity of a composite foundation, which includes a pile body 1, and the upper end of the pile body 1 is provided with a pile cap 2 that can be deformed under pressure to match the shape of its end face, such as figure 2 shown. The pile cap 2 should be made of a material whose compression modulus is equivalent to that of the foundation soil, such as extruded foam and other materials. The thickness can be 5-50 mm, and the optimum range is 10-30 mm. The extruded foam pile cap should be 100% continuous closed-cell structure, with certain compressive strength, good dimensional stability and weather resistance. Between the top of the pile cap 2 and the mattress layer 4, a pressure-resistant body 3 that prevents the mattress layer from piercing the extruded foam is additionally installed. The pressure-resistant body 3 can adopt a steel plate with a thickness of not less than 1.0 mm. In practice,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com