Sliding device

A technology of sliding device and transmission device, which is applied in the direction of transmission device, fluid transmission device, belt/chain/gear, etc., can solve the problems of low work efficiency and increased cost, and achieve the goal of improving work efficiency, easy implementation and reducing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

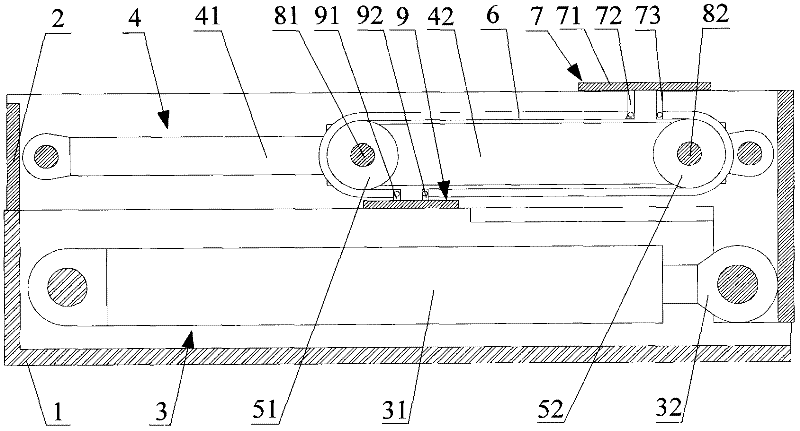

[0035] figure 1 A schematic cross-sectional view of a structure according to an embodiment of the present invention is shown.

[0036] Such as figure 1 As shown, the sliding mechanism in this embodiment includes a bracket 1 , a carriage 2 and a first oil cylinder 4 . The second oil cylinder 3, the primary rollers 51, 52, the primary transmission cable 6 and the workbench 7, the second oil cylinder 3 is a single-rod cylinder, and the first cylinder 4 is a double-rod cylinder.

[0037] The cylinder barrel 32 of the second oil cylinder 3 is hinged to the left end of the support 1, and the piston rod 31 of the second oil cylinder 3 is hinged to the lower right end of the carriage 2; The ends are hinged to the two ends of the carriage 2; there are two first-stage rollers, which are respectively the first-stage roller 51 and the second-stage roller 52; the first-stage roller 51 and the second-stage roller 52 are respectively connected to the left and right ends of the first oil c...

Embodiment 2

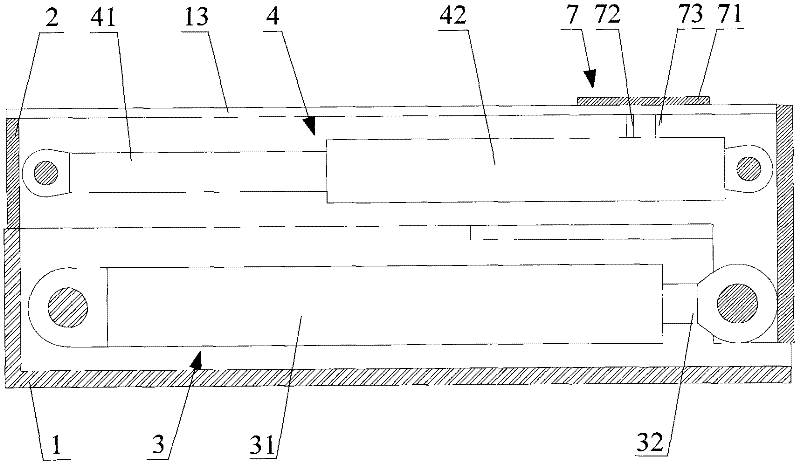

[0046] figure 2 A schematic cross-sectional view of a structure according to another embodiment of the present invention is shown.

[0047] Such as figure 2 shown, and refer to figure 1 , this embodiment includes a bracket 1, a carriage 2, a first oil cylinder 4, a second oil cylinder 3, and a workbench 7. The first oil cylinder 4 is a double-rod cylinder, and the second cylinder 3 is a single-rod cylinder, wherein, figure 2 Other content not shown in the figure 1 The same as shown in .

[0048] The two ends of described first oil cylinder piston rod 41 are hinged on the two ends of described carriage 2, and described carriage 2 is provided with the workbench slide rail 13 that supports described workbench 7, and described first oil cylinder barrel 42 is directly fixedly connected with the workbench 7. The cylinder barrel 32 of the second oil cylinder 3 is hinged to the left end of the support 1 , and the piston rod 31 of the second oil cylinder 3 is hinged to the low...

Embodiment 3

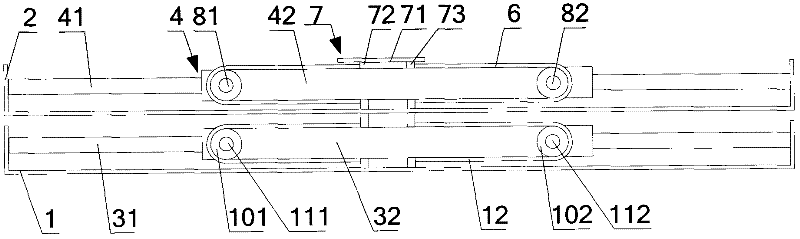

[0054] image 3 A schematic diagram of the principle according to yet another embodiment of the present invention is shown.

[0055] Such as image 3 shown, and refer to figure 1 , the present embodiment includes a bracket 1, a carriage 2, a first oil cylinder 4, a second oil cylinder 3, a primary roller, a primary transmission cable 6, secondary rollers 101 and 102, a secondary transmission cable 12, and a workbench 7. The first oil cylinder 4 is a double-rod cylinder, and the second cylinder 3 is also a double-rod cylinder. in, image 3 Other content not shown in the figure 1 The same as shown in .

[0056] The two ends of the first oil cylinder piston rod 41 are hinged to the two ends of the slide frame 2. There are two primary rollers, namely the first primary roller 51 and the second primary roller 52. The first-stage roller 51 and the second-stage roller 52 are respectively connected to the left and right ends of the first oil cylinder barrel 42 through the first-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com