Automatic dynamic adjustment method for synchronous extension of loop of cold rolling continuous processing line

A dynamic adjustment and processing line technology, applied in the direction of metal rolling, metal rolling, bending workpieces, etc., can solve the problems of increasing the difficulty of accident handling and accident recovery time, reducing the work efficiency of operators, and increasing the work intensity of operators, etc. Achieve the effect of shortening the accident recovery time, shortening the accident processing time, reducing the difficulty of strip steel stretching and re-welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

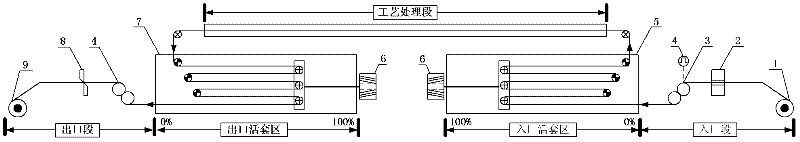

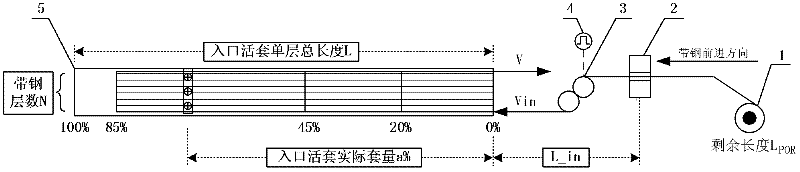

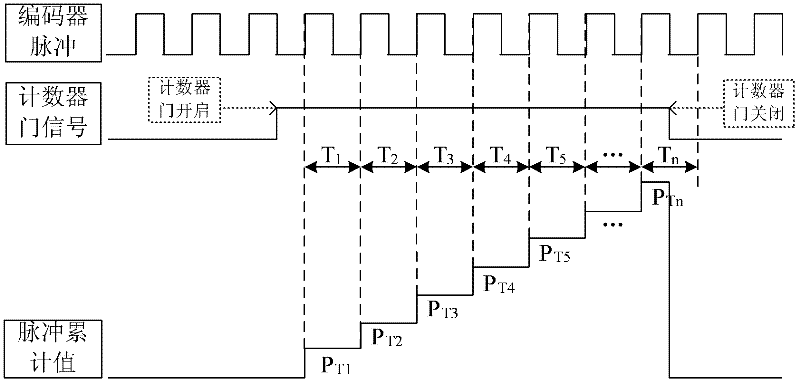

[0040] The automatic dynamic adjustment method for the amount of looper synchronous sleeves in the cold rolling continuous processing line provided by the present invention is specifically: according to the real-time running state of the strip steel on the processing line, when the entrance uncoiler is in the non-flicking stage, the tension roller at the entrance of the processing line is collected The number of pulse signals of the encoder on the screen is used to calculate the actual walking distance of the strip steel or the weld seam, so as to judge the relative position of the weld seam on the processing line and the looper, and automatically adjust the set value of the synchronous sleeve amount of the looper; The entrance uncoiler is in the tail-flicking stage, and the strip length to be supplemented is calculated according to the target setting value of the synchronous sleeve quantity of the looper and the current actual value, and compared with the length of the remainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com