Cable external-screen stripper

A cable and head stripping technology, used in cable installation, cable installation devices, equipment for dismantling/armored cables, etc. Simple structure, improved peeling and cutting precision, and the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

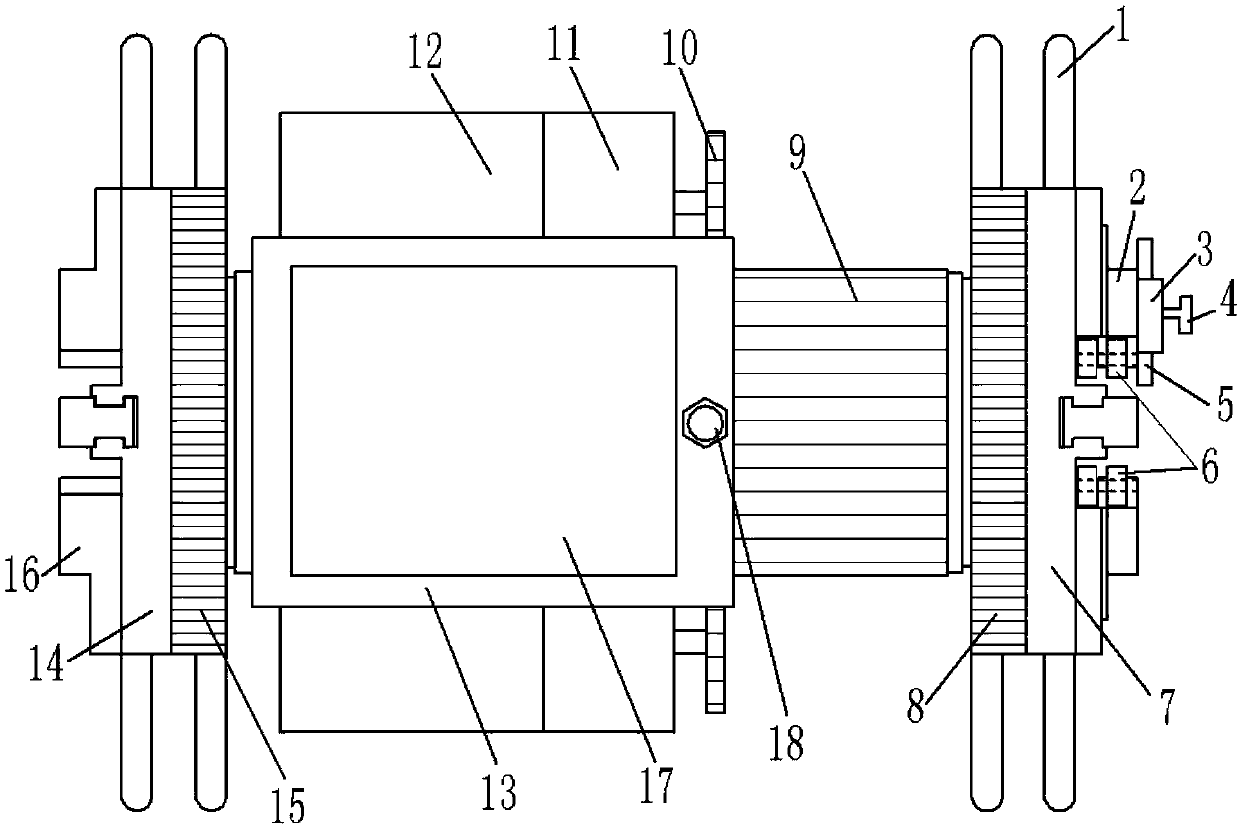

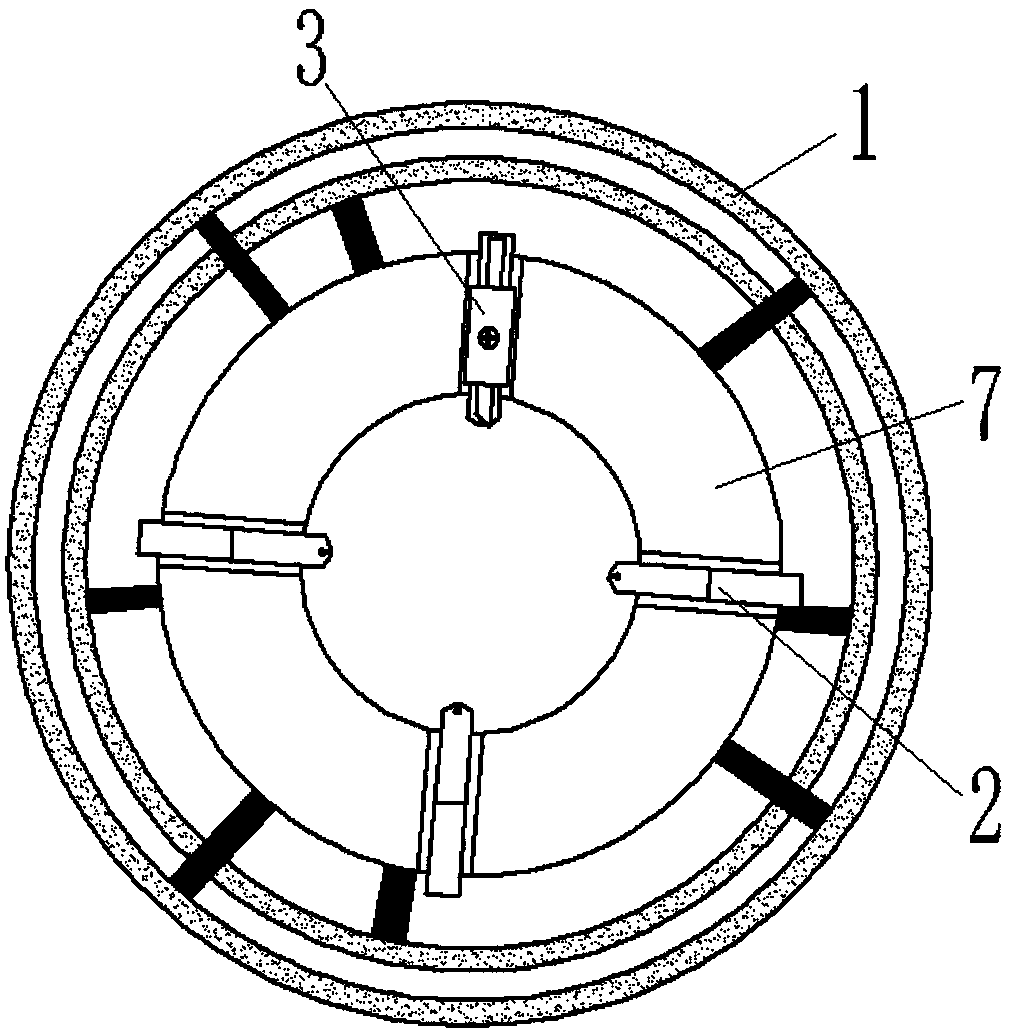

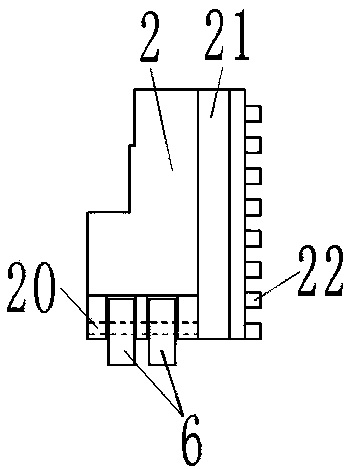

[0025] Such as Figure 1-7 As shown, a cable outer screen stripping device includes a housing 13, a transmission device, a cutter assembly, a movable stripping chuck 7 and a fixed chuck 14, and the fixed chuck 14 is fixedly connected to one end of the housing 13; the transmission device One end is connected in the other end of the housing 13 and can rotate relative to the housing 13, and the dynamic peeling chuck 7 is fixedly connected to the other end of the transmission device; the end of the transmission device connected in the housing 13 is connected with the housing 13 threads; 13. The transmission device, the fixed chuck 14 and the dynamic stripping chuck 7 are coaxially arranged, and holes for cables to pass through are respectively provided inside; the fixed chuck 14 and the dynamic stripping chuck 7 are also equipped with cable clamping and positioning components , the cable clamping and positioning assembly includes a fixed chuck push plate 15, a dynamic stripping ch...

Embodiment 2

[0032] Embodiment 2 is another structure of the transmission device, such as Figure 8 As shown, a transmission device of a cable outer screen stripper includes a hollow shaft 29, a rotating cylinder 31, a stator 32 and a rotor 33, the stator 32 is annular and is arranged on the inner wall of the housing 13, and the stator 31 is wound with a stator coil The rotating cylinder 31 is arranged coaxially with the housing 13 and has a through hole along the axial direction inside, the rotor 33 is arranged at one end of the rotating cylinder 31; the hollow shaft 29 is located in the housing 13 and one end passes through the housing 13 and the fixed card The disc 14 is fixedly connected; the end of the housing 13 close to the fixed chuck 14 has a clamping part extending radially to the outer wall of the hollow shaft 29, and the clamping part is fixedly connected to the outer wall of the hollow shaft 29, and the gap between the hollow shaft 29 and the housing 13 The part away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com