Conveying roller

A technology for conveying rollers and supporting rings, which is applied in the direction of conveyor objects, transportation and packaging, rollers, etc., which can solve the problems of increased belt tension, difficult alignment of conveying belts, and belt cracking, so as to prolong the service life and avoid bone damage. Material adhesion, to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments in the drawings:

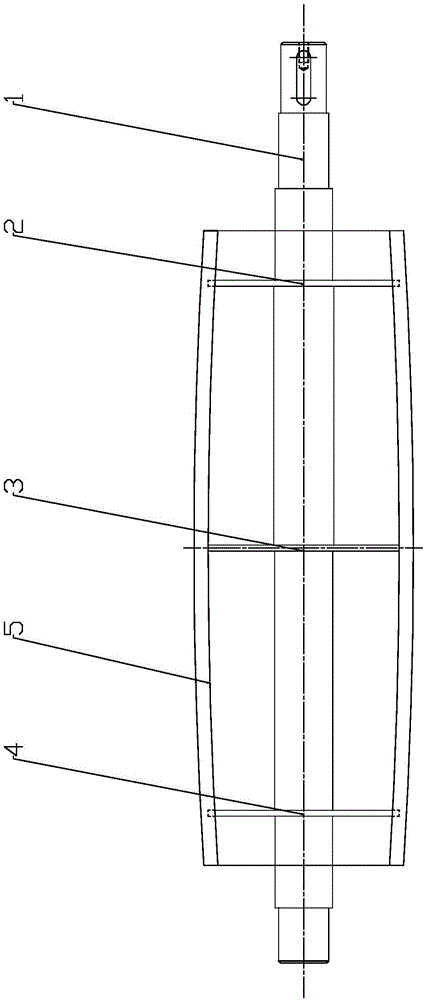

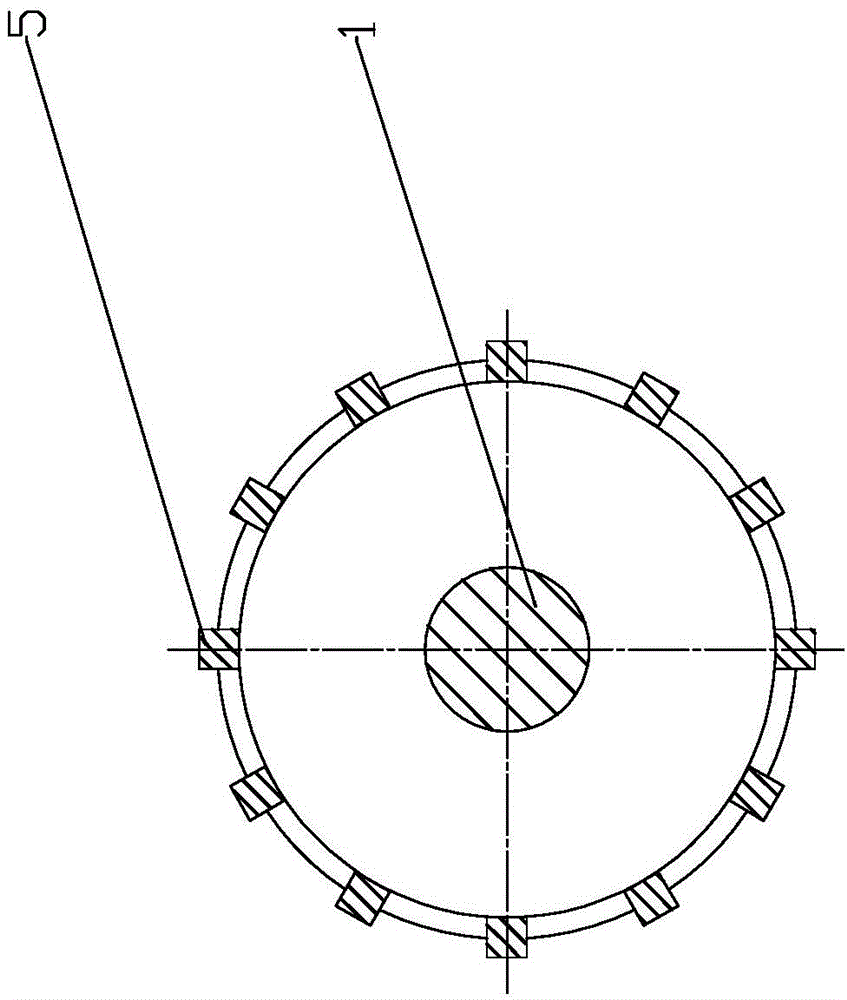

[0013] Such as Figure 1~2 As shown, the present invention mainly includes a transmission shaft 1, a middle support ring 3 is welded in the middle of the transmission shaft 1, and a left support ring 4 and a right support ring 2 are welded to the left and right ends of the transmission shaft 1 respectively.

[0014] The middle support ring 3, the left support ring 4 and the right support ring 2 have the same diameter. The left support ring 4 is evenly provided with multiple left grooves along the outer circumferential surface, and the right support ring 2 is evenly provided along the outer circumferential surface Multiple right grooves. The plurality of left grooves and the plurality of right grooves correspond one-to-one, and each corresponding left groove and right groove are in the same horizontal position.

[0015] A connecting strip 5 is welded together in each c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com