Sample barrel automatic transferring system

A sample barrel and automatic technology, applied in the field of sample barrel automatic transfer system, can solve problems such as sample interference, sample loss, and sample information leakage, and achieve the effect of ensuring reliability and reducing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

[0039] For convenience of description, the left end of the drawing is defined as the head, and the right end is defined as the tail.

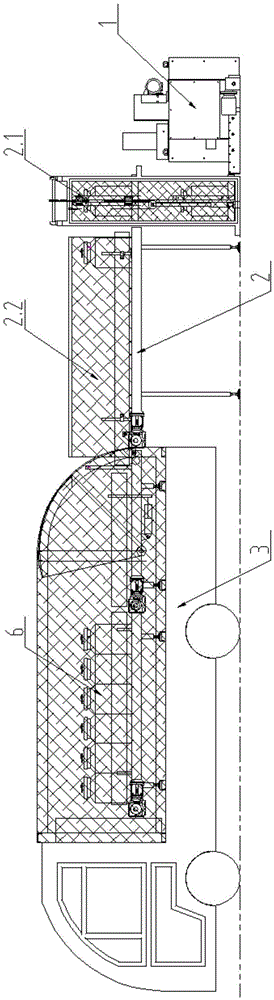

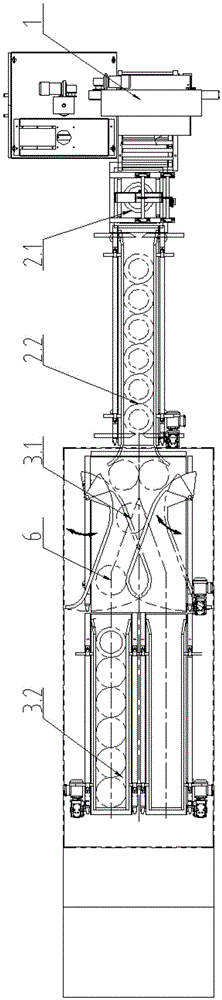

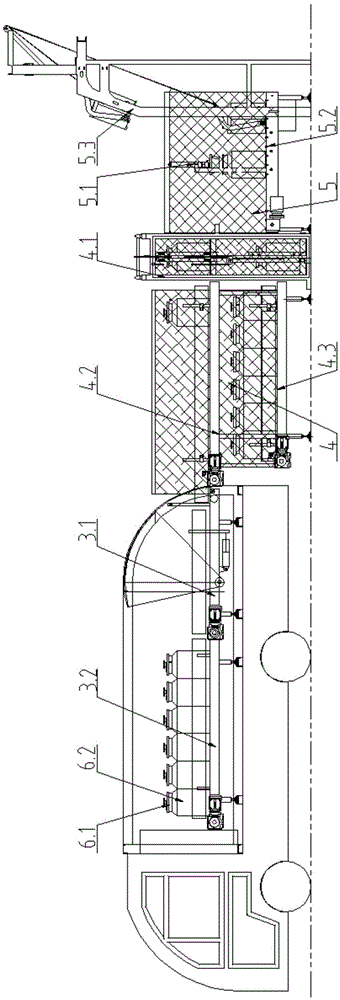

[0040] like Figure 1 to Figure 4 As shown, a sample barrel automatic transfer system includes a sample collector 1 and a transfer car 3, and the sample barrel 6 that has completed sample collection is output from the sample collector 1 and transferred to the sample preparation place by the transfer car 3; it also includes a loading Conveying device 2, unloading conveying device 4 and automatic unloading device 5;

[0041] The sample collector 1 is an automatic entry and exit collector, including a collector 1.1, a clamping mechanism 1.2 and a conveying device 1.3 arranged on the side of the collector, and the clamping mechanism 1.2 holds the The sample barrel 6 is taken out from the collector 1.1, and the conveying device 1.3 transfers th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com