Airborne anchor rod drilling machine

A bolter drilling rig and frame technology, which is applied in the installation of bolts, rotary drilling rigs, earthwork drilling and mining, etc. It can solve the problems of unsatisfactory positioning accuracy of drilling positions, large swinging range of drill pipes, and lack of limit parts, etc. , to achieve the effect of improving the quality of the anchor hole, reducing the swing range, and not easy to deviate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

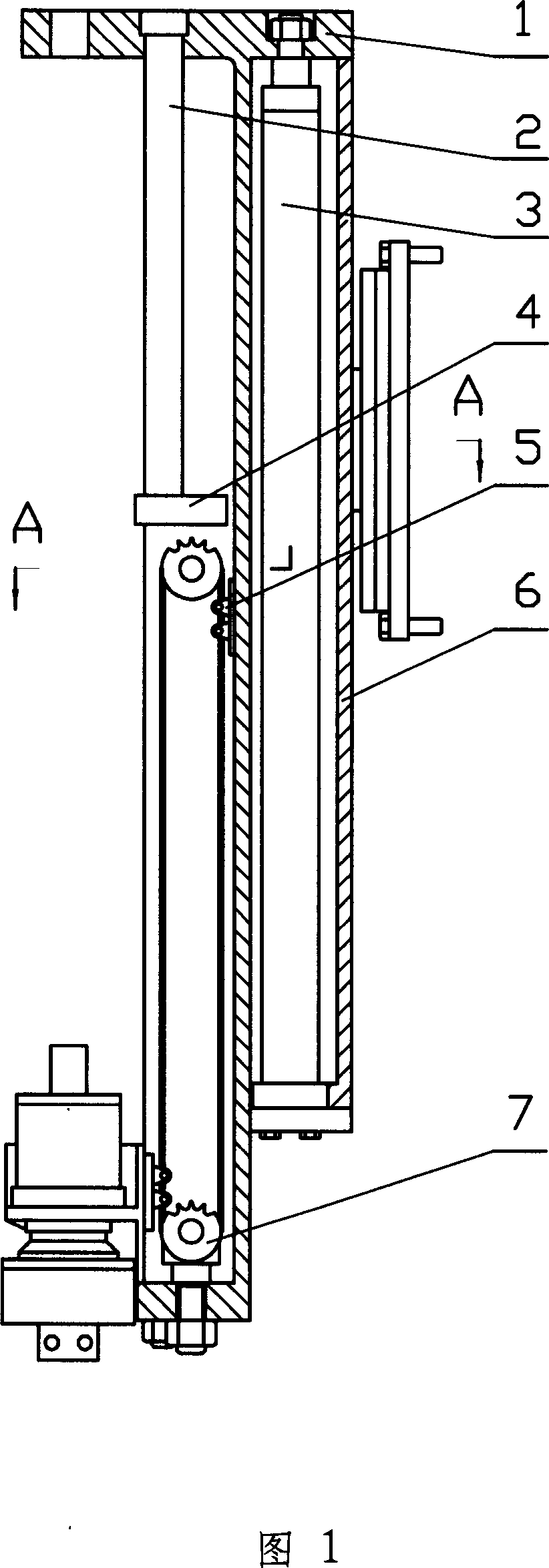

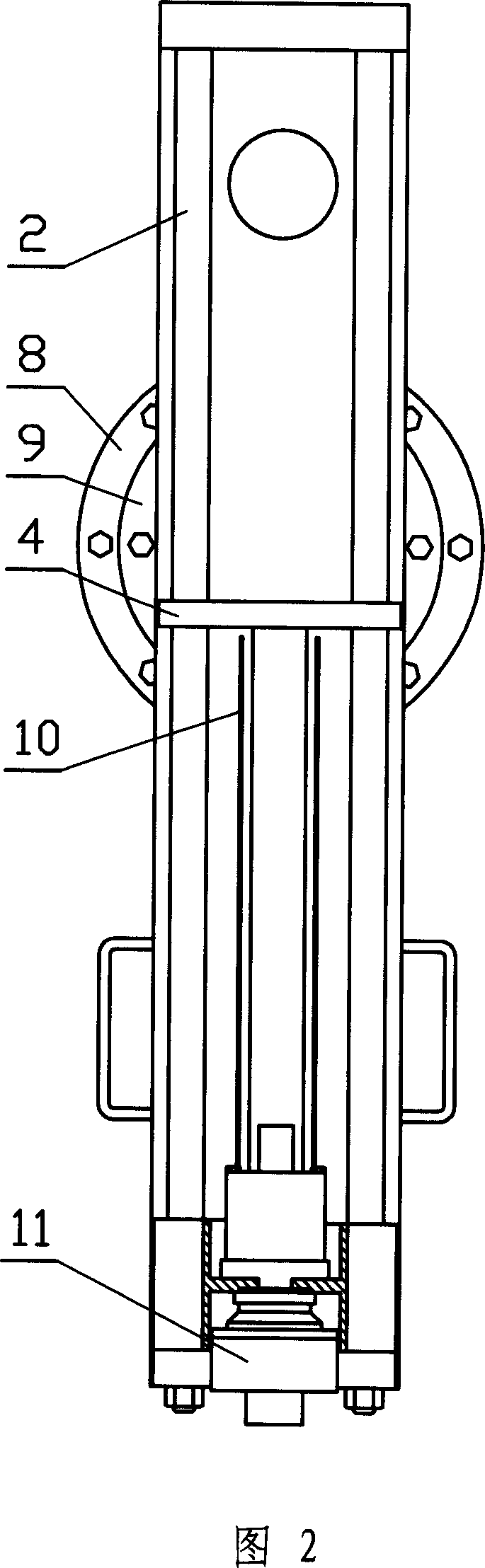

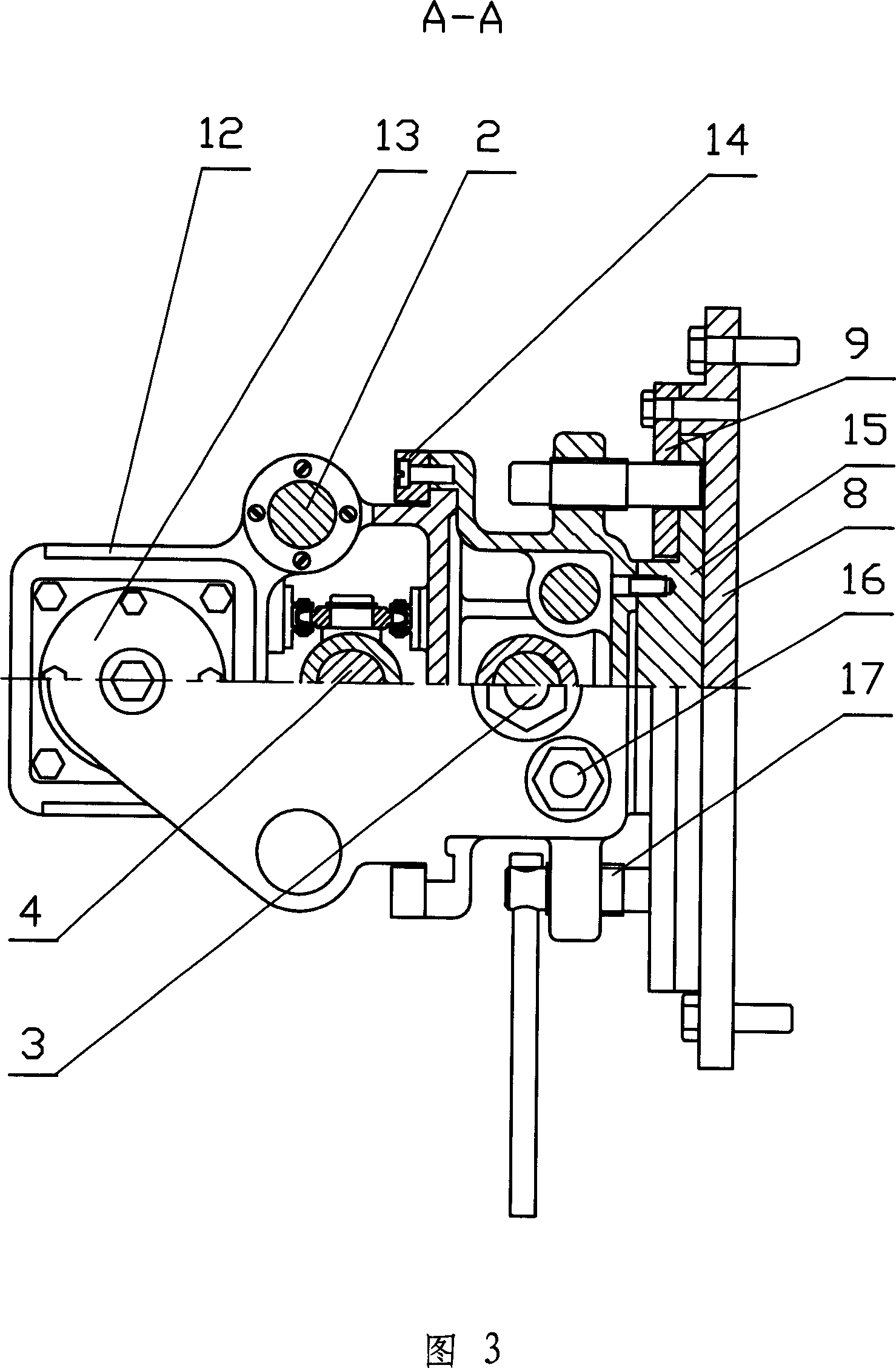

[0017] Shown in Fig. 1, Fig. 2, Fig. 3, the present invention comprises hydraulic motor, oil cylinder, support fixing mechanism, supporting mechanism, feeding mechanism and drilling mechanism. The rear bracket 6 is screwed together with the transition plate 14, the transition plate 14 is embedded in the connecting rotating body 8, the pressure ring 9 covers the transition plate 14 and is fixedly connected with the connecting rotating body 8 with bolts, after the above installation, the transition The disk 14 is free to rotate in the cavity formed between the pressure ring 9 and the coupling rotor 8 . Fix the bead 13 on the rear bracket 6 with screws, and insert the front bracket 1 into the chute formed by the bead 13 and the rear bracket 6 at the same time. After the above installation, the front bracket 1 and the rear bracket 6 should be able to move along the chute Slip fit. After one end of support guide post 15 passes through the guide hole on the rear support 6, it is sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com