Four-corner case sealer

A box sealing machine and four-sided corner technology, applied in conveyors, packaging sealing/fastening, external support, etc., can solve the problems of easy sticking of tapes, easy deviation of cartons, unstable mechanical properties, etc., and achieve stable mechanical properties. , The effect of increasing sealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

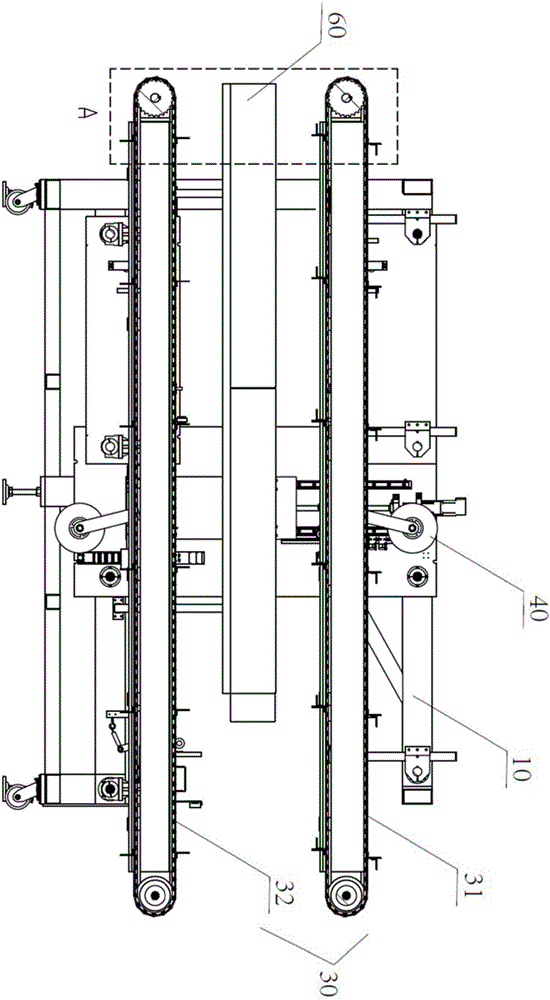

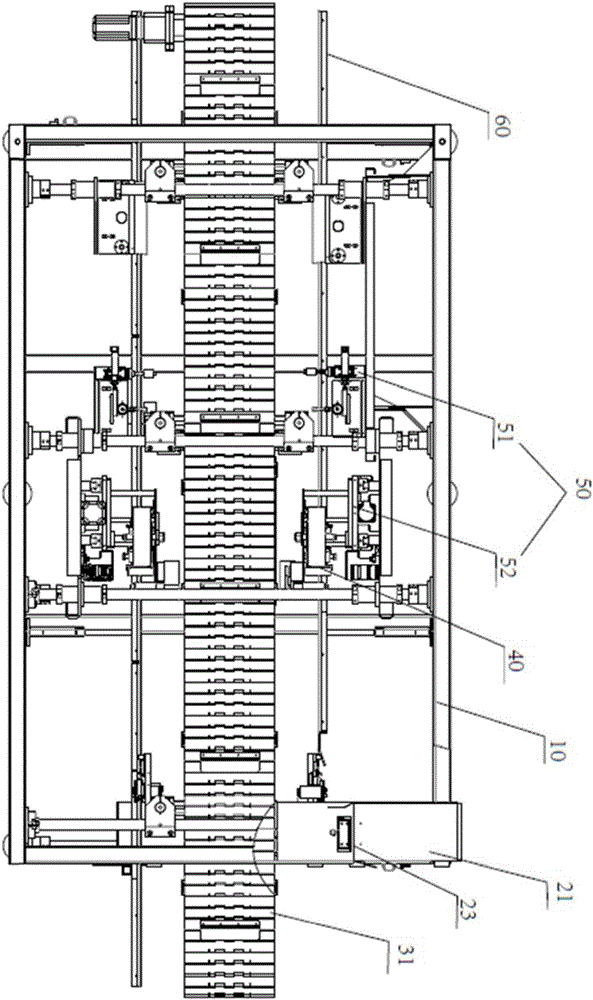

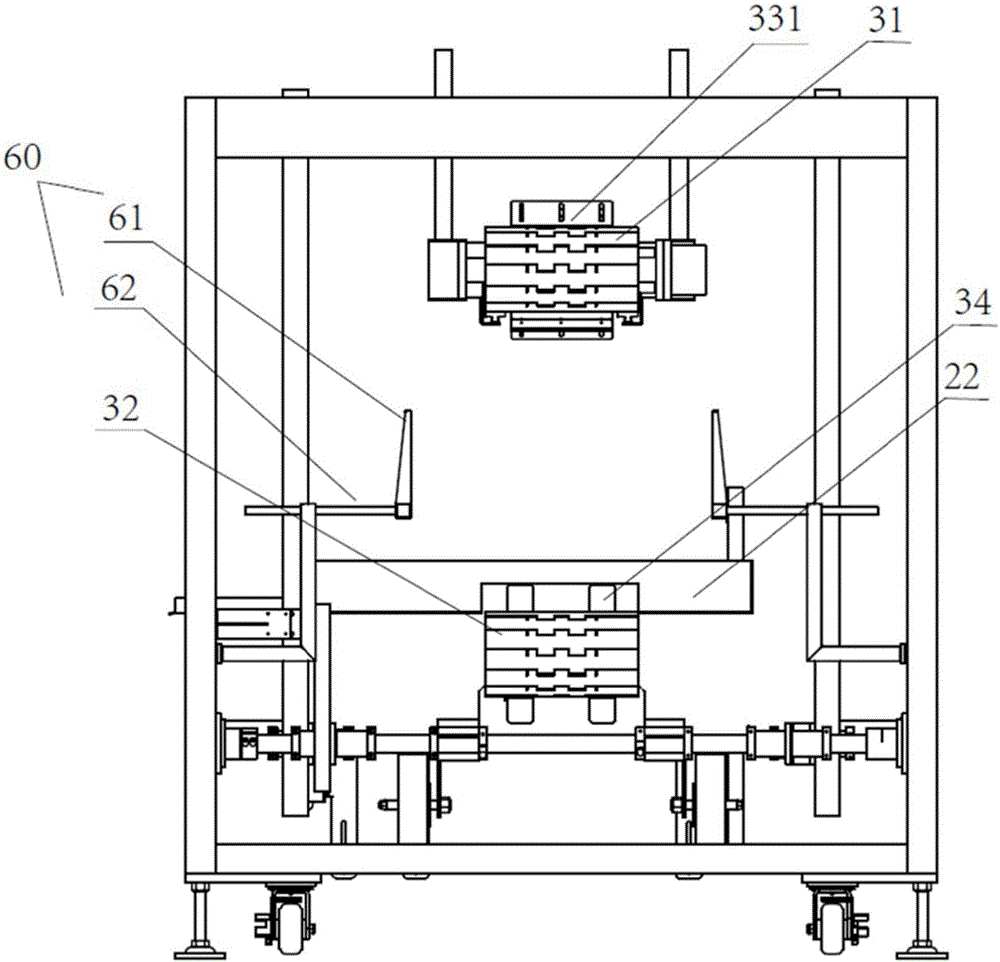

[0026] see figure 1 , figure 2 with image 3 As shown, a four-sided corner sealing machine of the present invention includes a frame body 10, an auxiliary mechanism for entering the box 20, a conveying mechanism 30, a tape sticking mechanism 40 and a brushing mechanism 50, and the conveying mechanism 30 is installed on the frame body Above, the box entry auxiliary mechanism 20 is installed at the entrance of the conveying mechanism 30 , and the tape attaching mechanism 40 and the leveling mechanism 50 are installed on the frame body 10 and located on both sides of the conveying mechanism 30 .

[0027] Specifically, the conveying mechanism 30 includes an upper conveying belt 31 and a lower conveying belt 32, the upper conveying belt 31 and the lower conveying belt 32 are also provided with positioning parts, and the two sides of the conveying mechanism 30 are also provided with left and right fixing mechanisms. 60, such as Figure 4 , Figure 5 with Image 6 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com