Cloth pulling and feeding mode of cutting machine and cloth pulling and feeding device of cutting machine

A feeding device and cutting machine technology, applied in the direction of spreading thin soft materials, thin material handling, transportation and packaging, etc., can solve the problems of easy deviation, short stroke, inconvenient assembly and maintenance, etc., to achieve easy assembly and maintenance , The feeding structure is simple, and the effect that it is not easy to deviate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

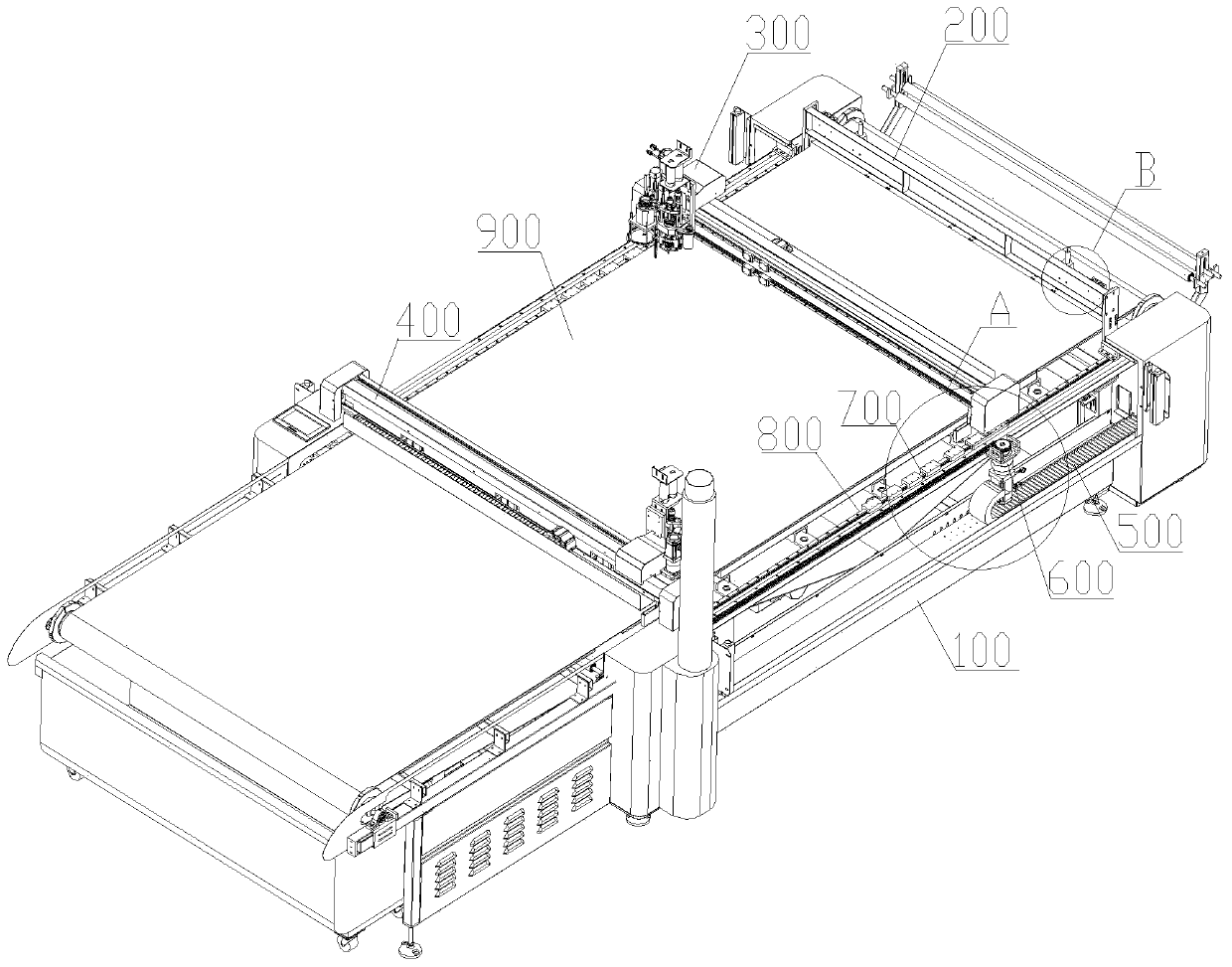

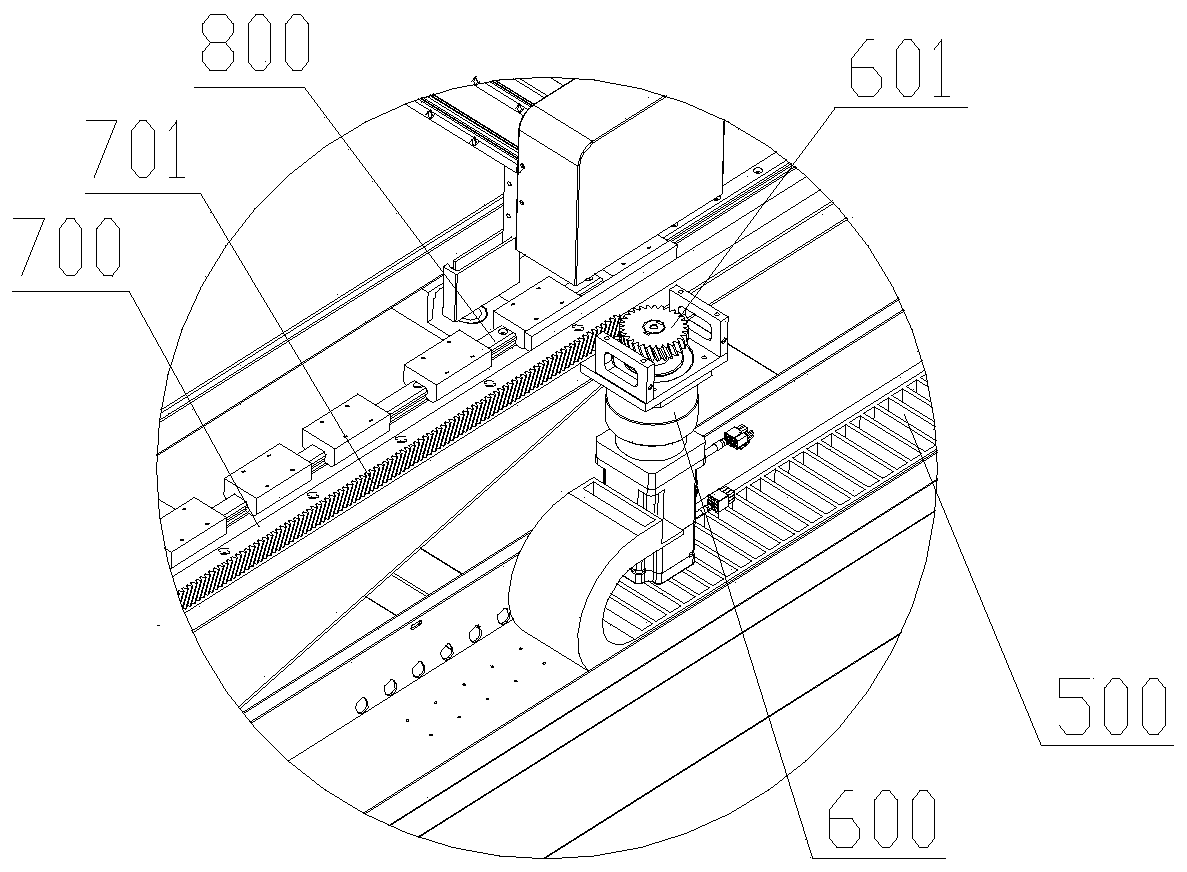

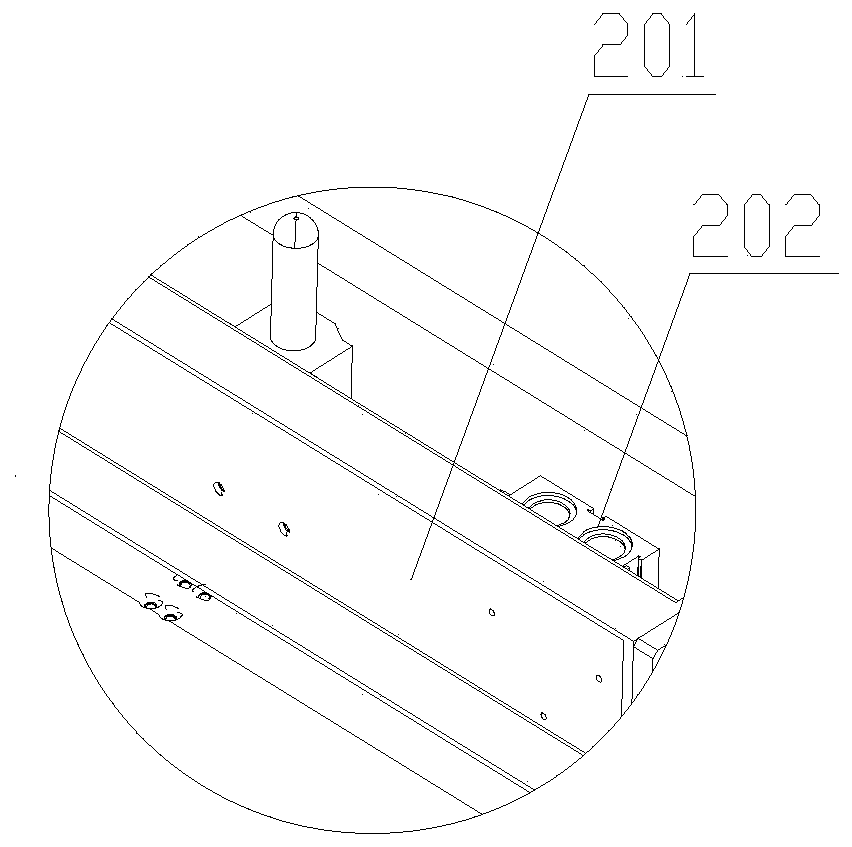

[0024] see Figure 1 to Figure 4 As shown, a cloth feeding device for a cutting machine, the two ends of the frame 100 are respectively provided with a first pressing assembly 200 and a second pressing assembly 400, and the two sides of the frame 100 are respectively provided with a driving assembly 600, and the frame 100 is provided with a slide rail 800, and a slide assembly 700 is provided on the slide rail 800. The slide assembly 700 and the cloth assembly 300 are fixed to each other, and the cloth assembly 300 is located between the first compression assembly 200 and the second compression assembly 400, The driving assembly 600 and the sliding assembly 700 are connected in transmission, and the frame 100 is also provided with tension rollers, which tighten the endless conveyor belt 900 (the tension is appropriate, but not too tight, which will affect the endless conveyor belt 900 being dragged by the magnetic attraction). moving), the endless conveyor belt 900 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com