Peeler of aluminum-plastic plates

A stripping machine and aluminum-plastic panel technology, which is applied to layered products, lamination auxiliary operations, lamination, etc., can solve the problems affecting the recycling process of aluminum-plastic panels and low stripping efficiency, and achieve high stripping efficiency and convenient stripping control , Guarantee the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

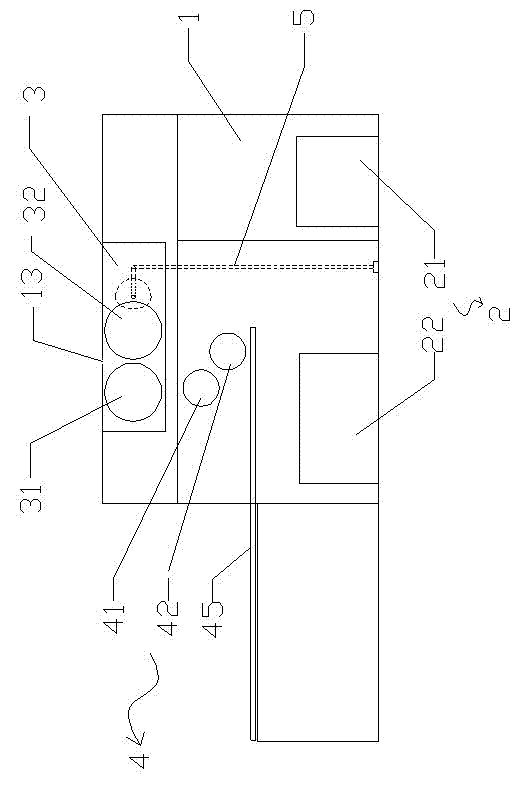

[0025] see Figure 1~Figure 5 , The present invention relates to an aluminum-plastic panel peeling machine, which includes a frame 1, and the frame 1 is provided with a power mechanism 2, a peeling mechanism 3, a discharging mechanism 4 and a clutch mechanism 5,

[0026] The power mechanism 2 is arranged at the bottom of the frame 1, and the power mechanism 2 includes a speed regulating motor 21 and a gearbox 22. The output end of the motor 21 is connected with the input end of the gearbox 2 through a belt.

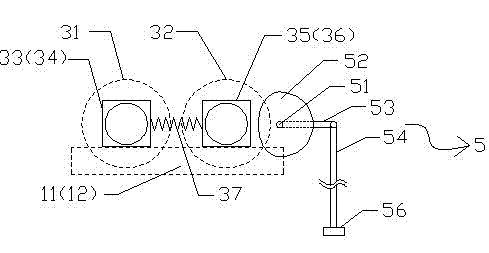

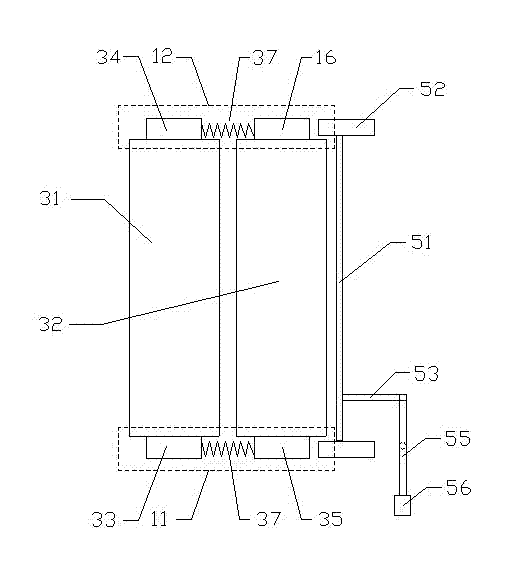

[0027] The peeling mechanism 3 is arranged on the upper part of the frame 1, and the upper part of the frame 1 is provided with a front rail 11 and a rear rail 12 arranged in front and rear, and the peeling mechanism 3 includes rollers I31 and II32 arranged left and right, The roller I31 and the roller II32 are both knurled rollers. The frame 1 just above the middle of the roller I31 and the roller II32 is provided with a feeding port 13, and the front rail 11 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com