Rotary type water-cooled fire grate

A water-cooled grate and rotary technology, applied in the directions of rotary grate, rocking grate, grate, etc., can solve the problems of insufficient fuel combustion, narrow application range, waste of wind energy, etc., and achieve long service life, suitable for Wide-ranging, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

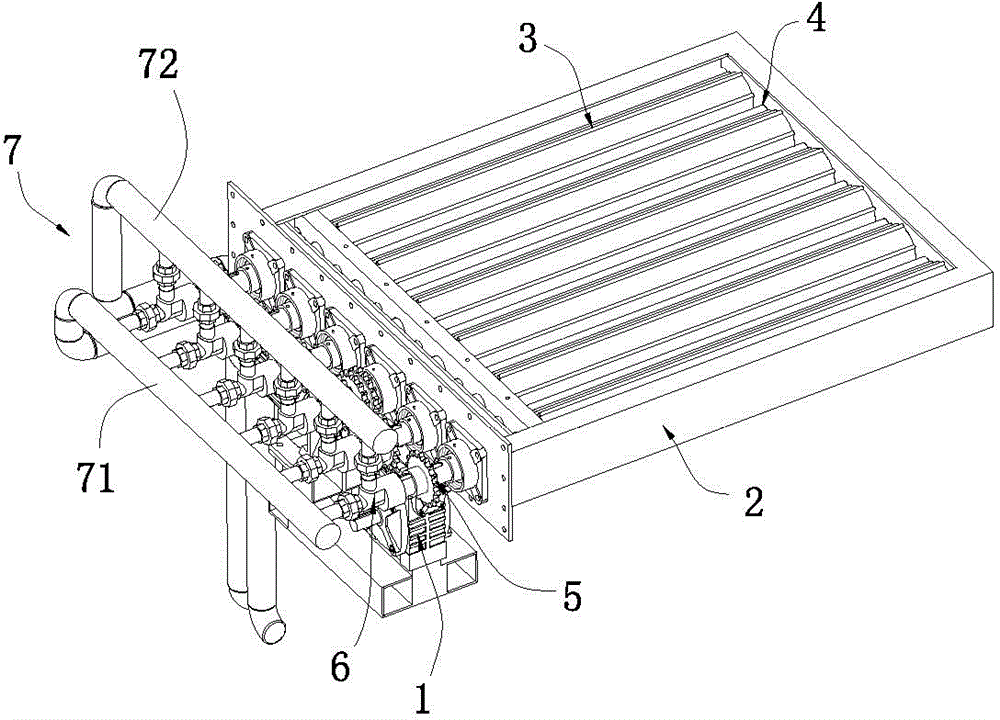

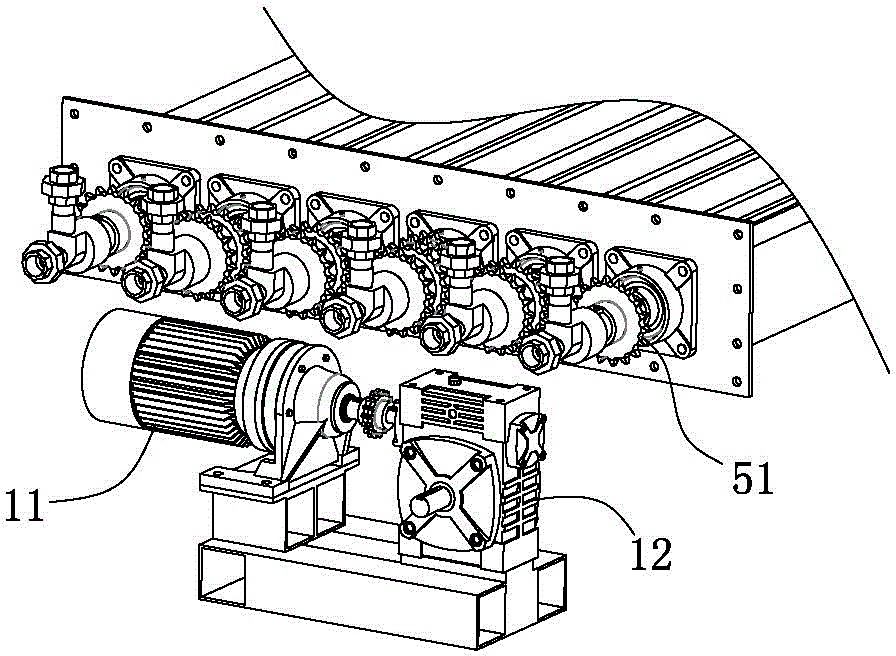

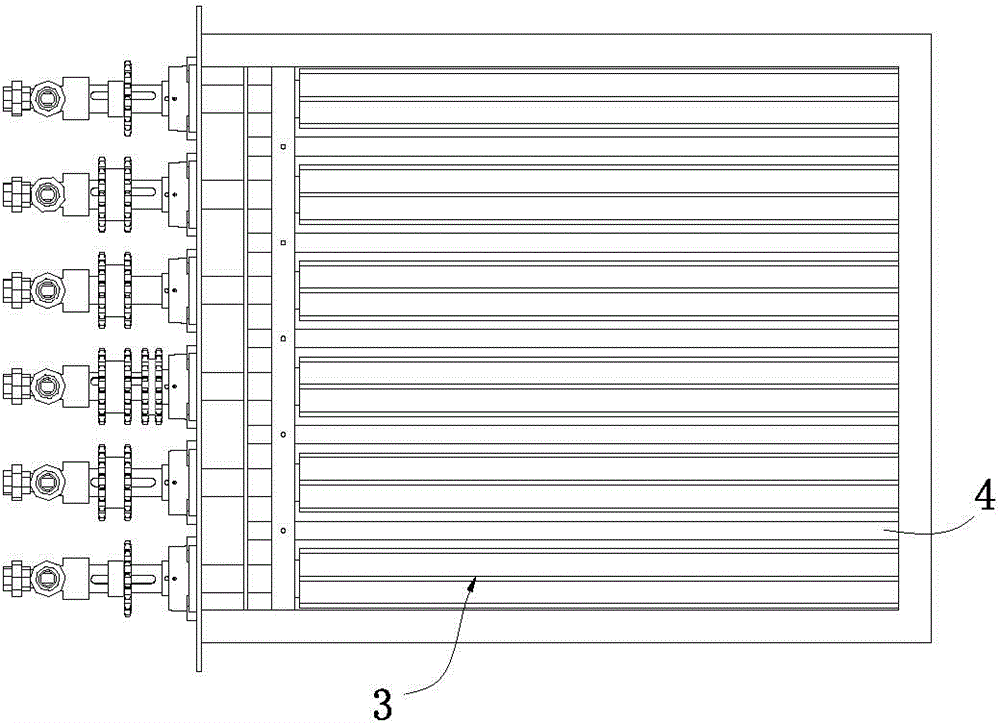

[0017] Examples, see Figure 1 to Figure 5 , a rotary water-cooled fire grate provided in this embodiment, which includes a driving device 1, an installation frame 2, a large rotating row pipe 3 and a small fixed row rod 4, and a plurality of large rotating row pipes 3 are arranged in parallel at intervals on the installation On the frame 2, the small fixed row rod 4 is fixedly arranged on the installation frame 2 corresponding to the position between the adjacent two large rotating row pipes 3, and is parallel to the large rotating row pipe 3, and the driving device 1 is set It is located on one side of the installation frame 2, and is connected with all the large rotating pipes 3 through the transmission assembly 5, and can drive them to rotate. One end of the large rotating pipe 3 is provided with a rotating water shaft 6. The rotating water shaft 6 is connected with a circulating water cooling system 7 . The circulating water cooling system 7 includes a water tank and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com