Low-energy-consumption buoyancy pushing type scum scraping device

A slag scraping device and propulsion technology, which can be used in flotation water/sewage treatment, cleaning hollow objects, chemical instruments and methods, etc. Automatic operation, high degree of automation, solving the effect of large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

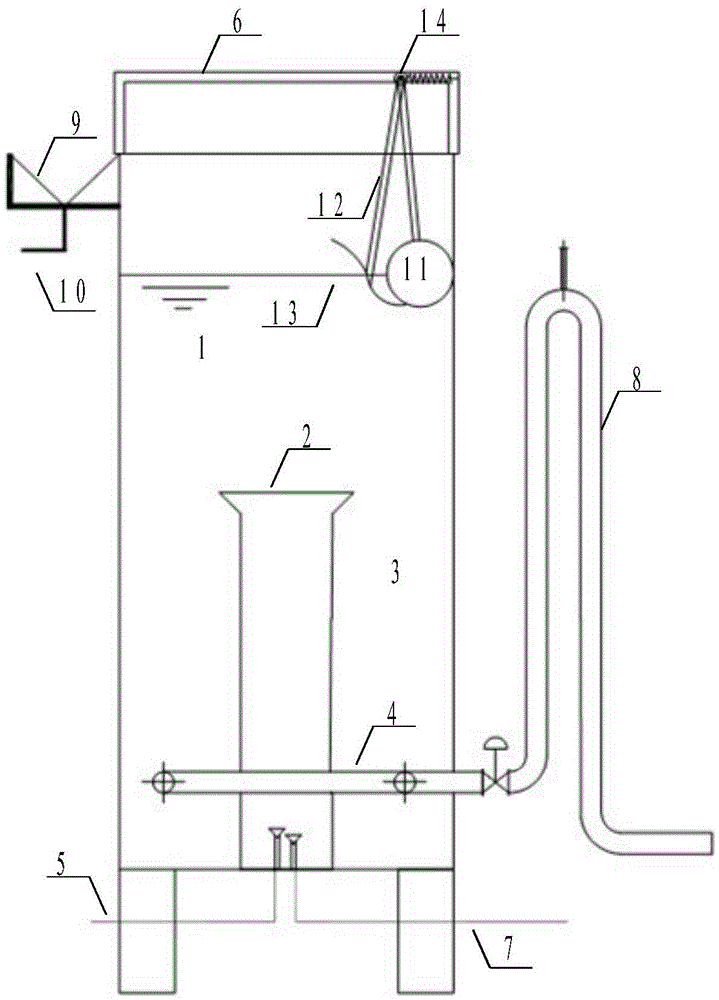

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

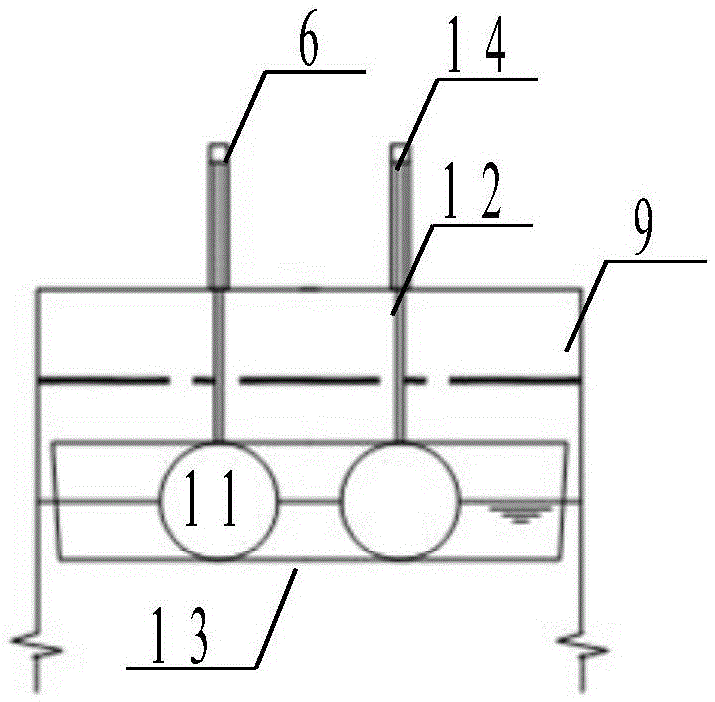

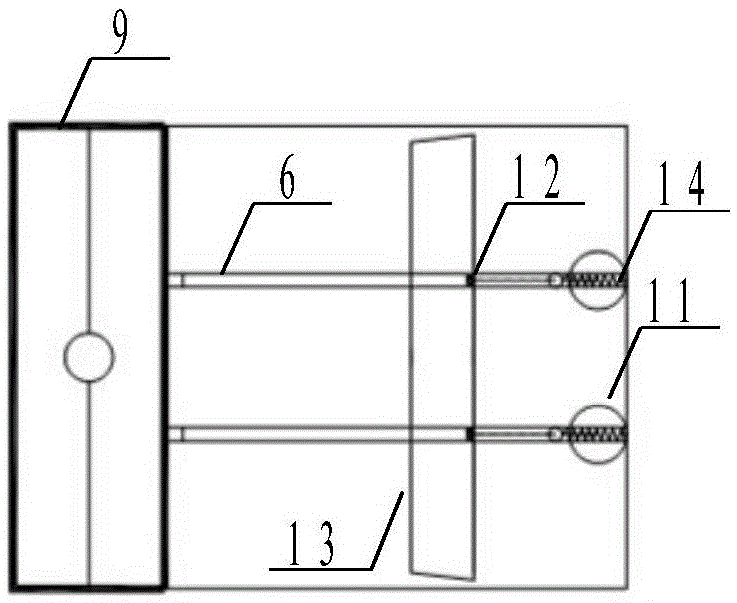

[0020] Such as figure 1 As shown, a low energy consumption buoyancy propulsion type slag scraping device includes a floating ball 11 arranged in the ozone gas floating cylinder 1, and the floating ball 11 is connected to the track bracket 6 on the top of the ozone gas floating cylinder 1 through an expansion and contraction bracket 12 Above, the track support 6 is a parallel double track, and the structure and the parts arranged thereon are exactly the same.

[0021] The expansion bracket 12 is an inverted V-shaped structure, which is connected by two rods through a horizontal shaft. The lower end of the rear rod is connected to the floating ball 11, and the lower end of the front rod is connected to the curved slag scraper 13 with the inner arc facing downward. The horizontal rotating shaft is slidably arranged on the track support 6 and is pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com