Single body large-diameter pneumatic down-the-hole hammer

A down-the-hole hammer and large-diameter technology, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc., can solve the problems of difficult processing, unbalanced working status, piston wear, etc., and achieve a compact and reasonable structure , good slag removal effect, anti-abrasion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The single large-diameter pneumatic down-the-hole hammer of the present invention will be described in detail below in conjunction with the accompanying drawings:

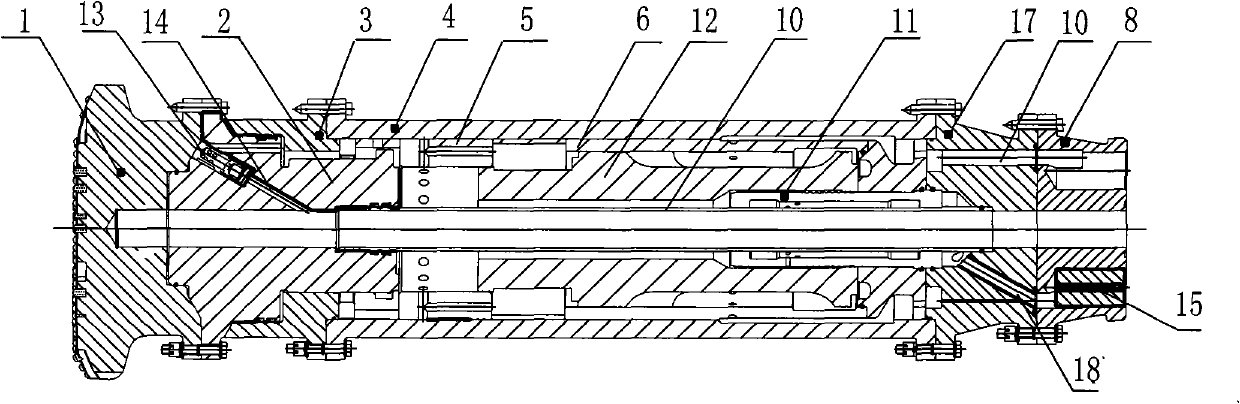

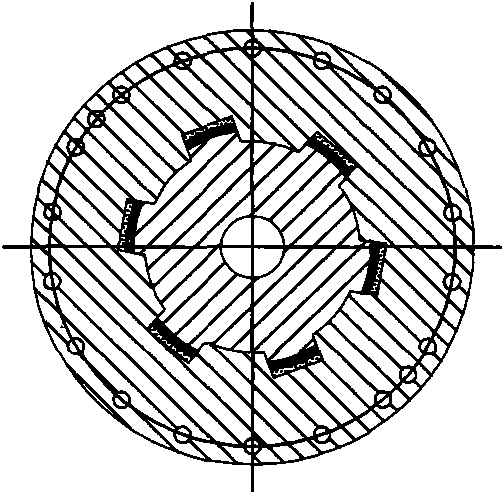

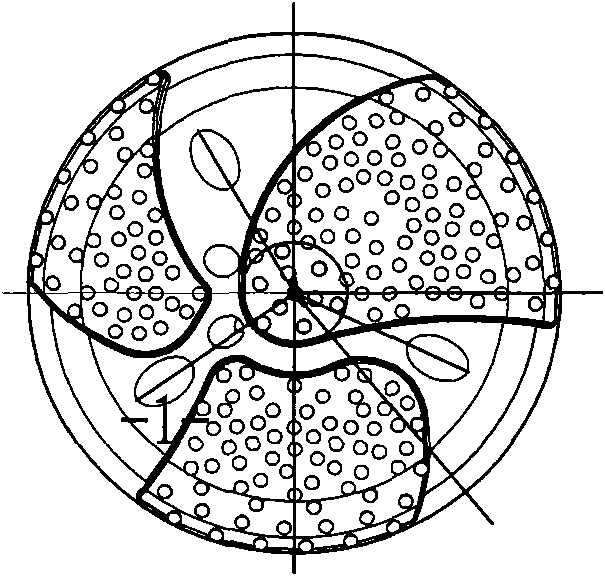

[0017] Such as figure 1 As shown, the single large-diameter pneumatic down-the-hole hammer of the present invention includes a swirl drill bit 1, a spline shaft 2, a spline sleeve 3, a cylinder block 4, an air distribution sleeve 5, a bushing 6, an upper flange 7, Transition flange 8, piston 12 and central air pipe, the above components are arranged coaxially in sequence, the outside is connected by a shock-absorbing and anti-loosening bolt group, the internal is contacted by the end face and axially positioned by a spacer, the central air pipe is installed in the inner hole of the piston, In order to improve its working performance, the cylinder body 4 of the pneumatic down-the-hole hammer of the present invention selects a single cylinder body, and the central gas pipe is a double-core tube 9, which is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com