Granular heat-preserving covering flux for hot metal in steelmaking

A technology of thermal insulation covering agent and iron and steel water, which is applied in the field of treatment agent for thermal insulation on the surface of iron and steel water, which can solve the problems of poor thermal insulation effect, poor spreadability, and high melting point of carbonized rice husks, so as to facilitate slag cleaning operations, reduce dust pollution, Good spreading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Under normal temperature and pressure, first check the chemical composition of the raw materials.

[0025] (2) Crushing and screening the raw materials, the particle size is required to be 2-3mm.

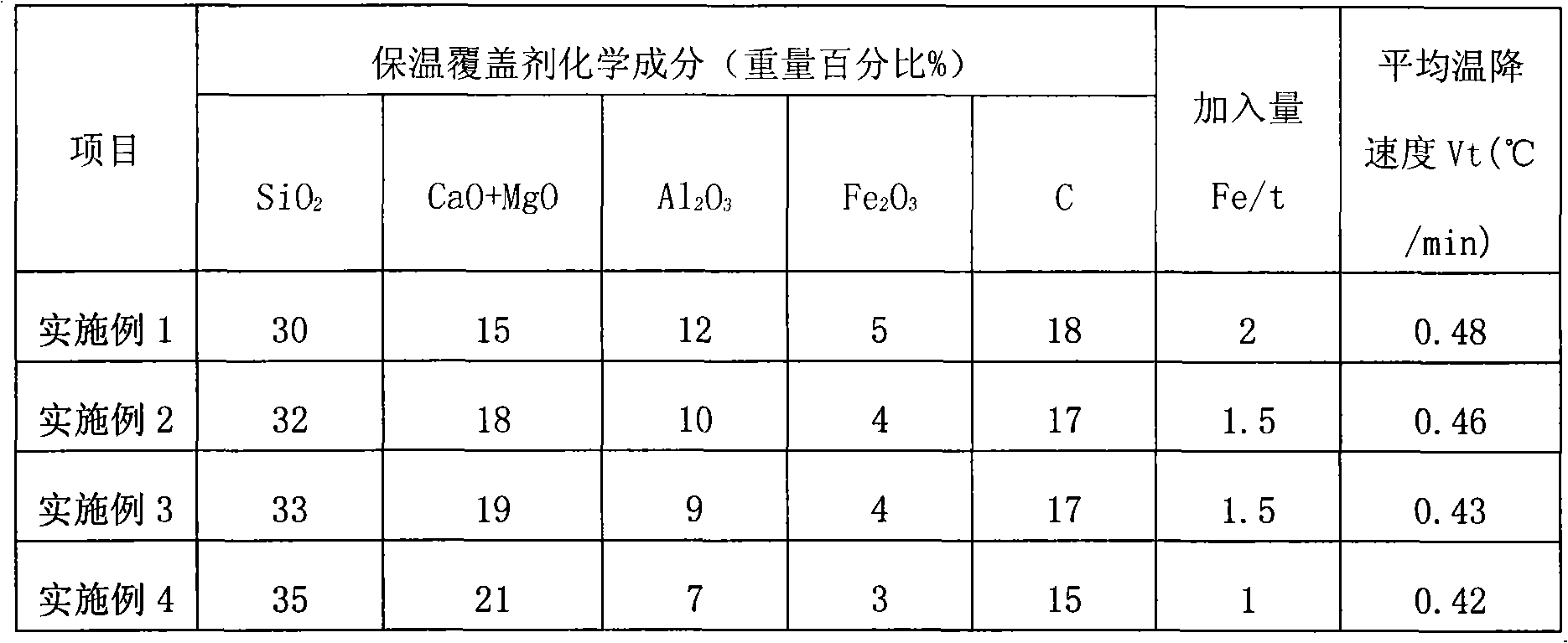

[0026] (3) Carry out batching by weight percentage of each component in Table 1.

[0027] (4) The mixer is mixed and stirred evenly.

[0028] (5) Weigh and bag after drying and cooling.

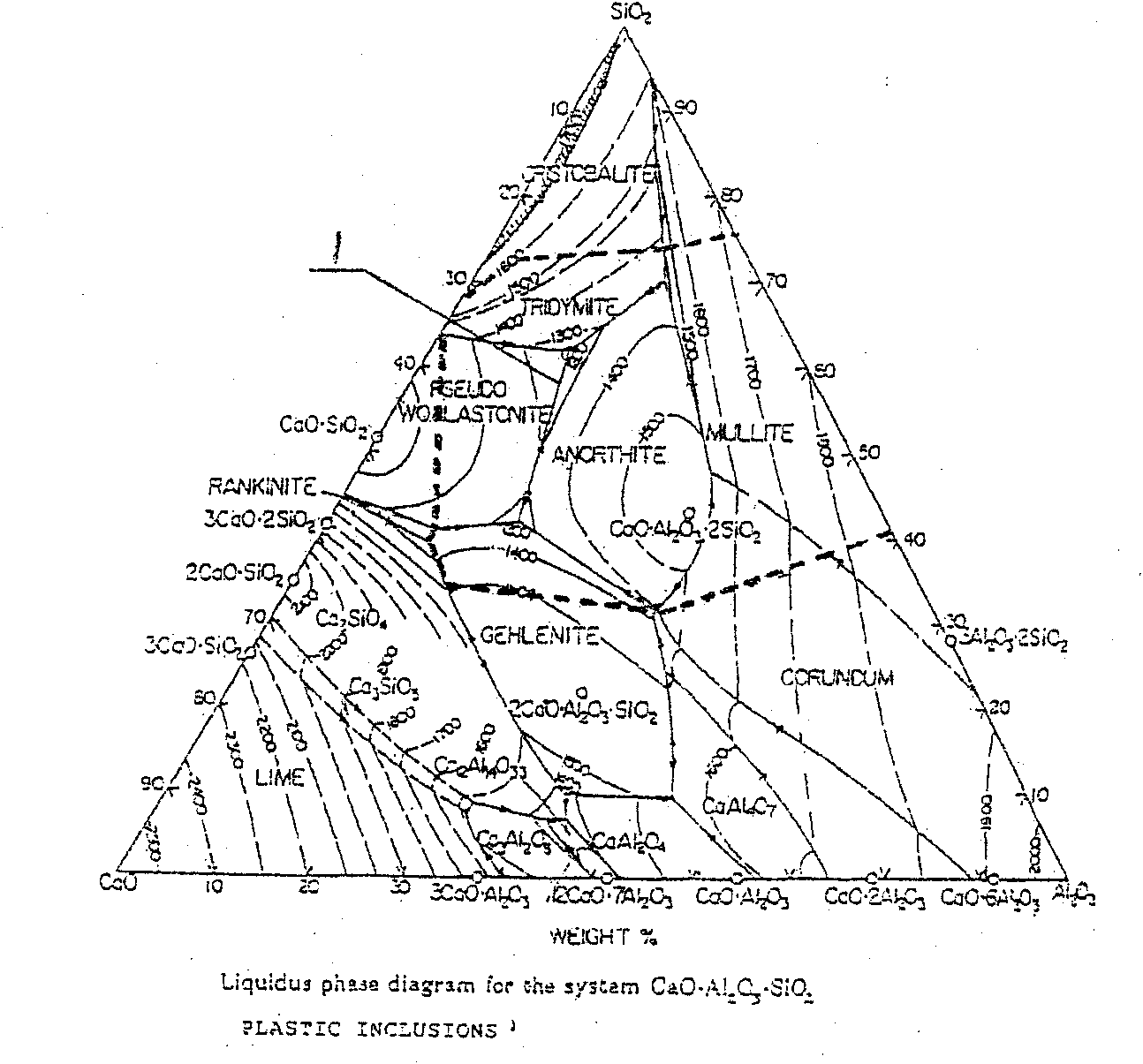

[0029] Depend on figure 1 It can be seen that curve 1 is the melting point region of the covering agent, and the melting point in this region is between 1200°C and 1300°C.

[0030] application test

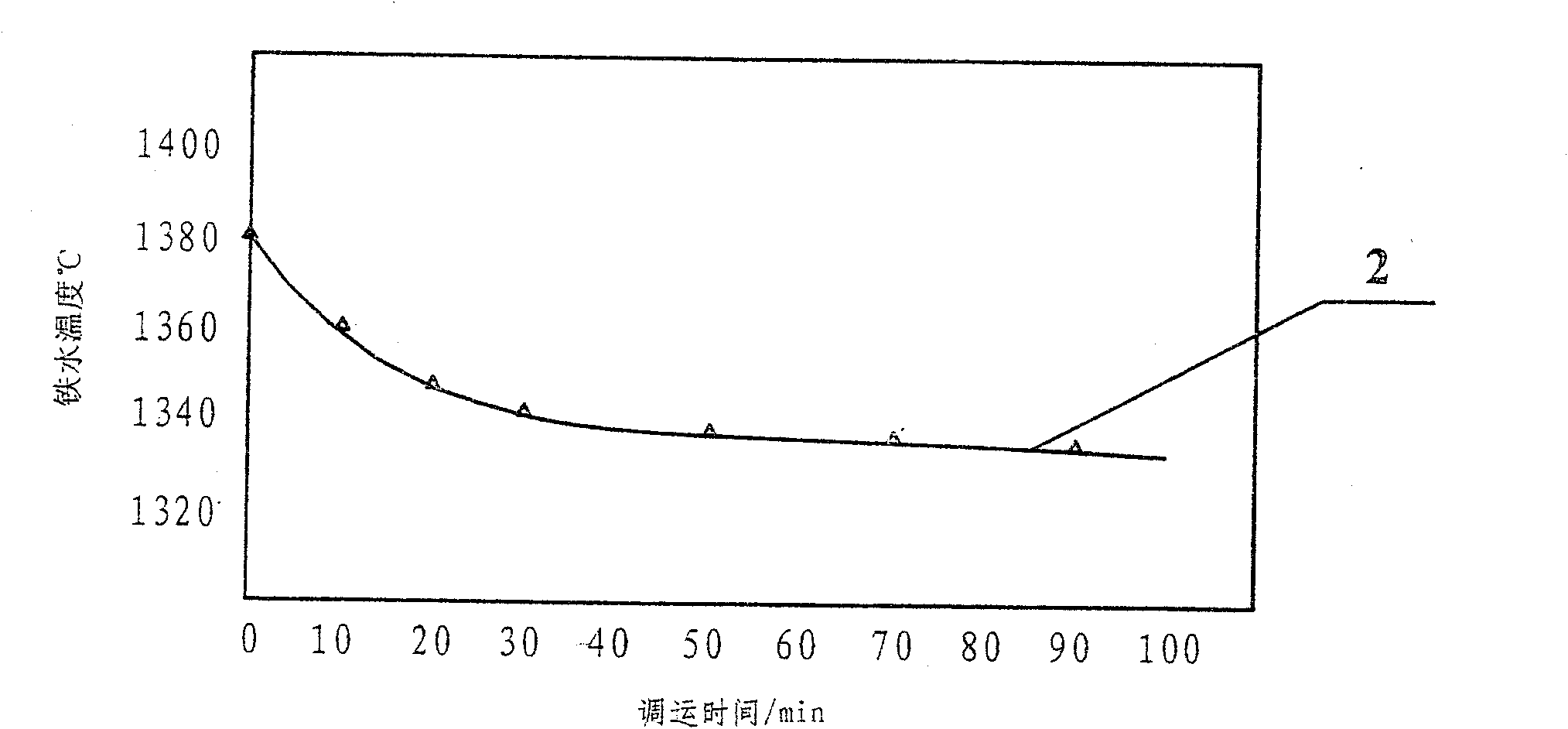

[0031] The test was carried out in a 60-ton molten iron tank. The amount of thermal insulation covering agent added was 1.0Kg / t of molten iron. After ironing, add the remaining 1 / 4 at the point where the molten iron falls. Measure the temperature immediately after tapping stops. After the molten iron tank is transported to the steel plant, the temperature of the molten iron in the lad...

Embodiment 2

[0033] Preparation and use test according to the method of Example 1, the composition of each component, the amount of iron added per ton and the temperature drop rate are listed in Table 1.

Embodiment 3

[0035] Preparation and use test according to the method of Example 1, the composition of each component, the amount of iron added per ton and the temperature drop rate are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com