Straw gasification combustor

A combustion furnace and straw technology, applied in the direction of combustion method, combustion equipment, fixed bed gasification, etc., can solve the problems of difficulty in utilizing straw combustion characteristics, low combustion efficiency, etc., achieve good combustion effect, simple ignition, and strong output capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

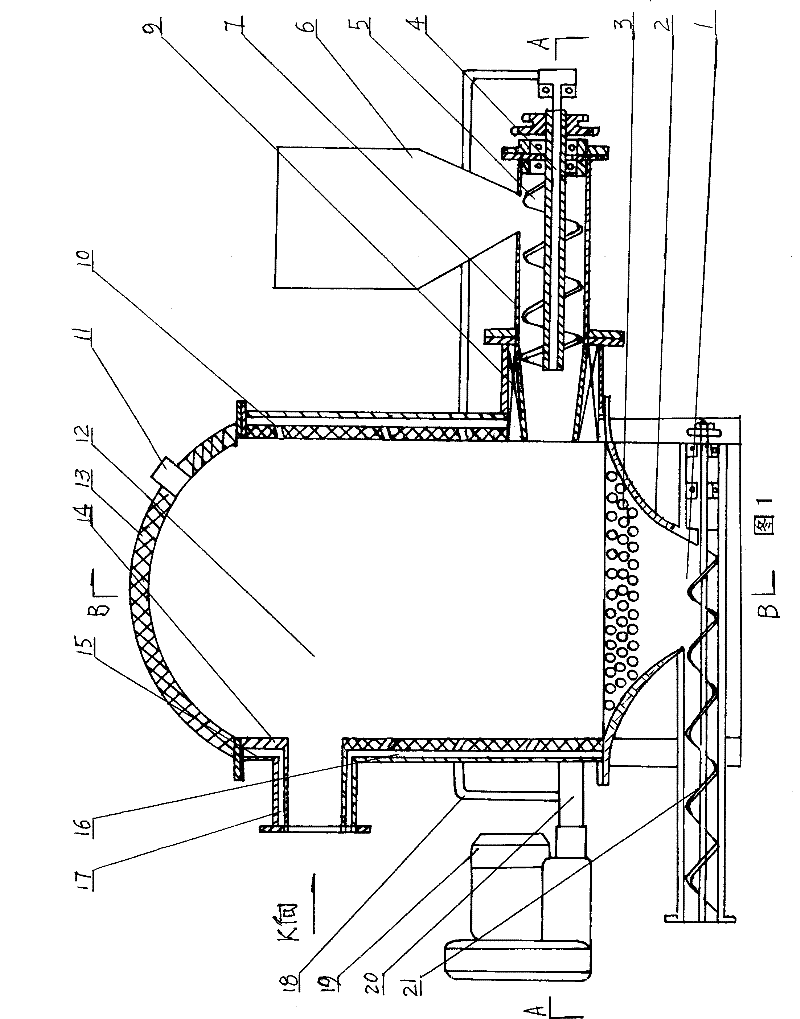

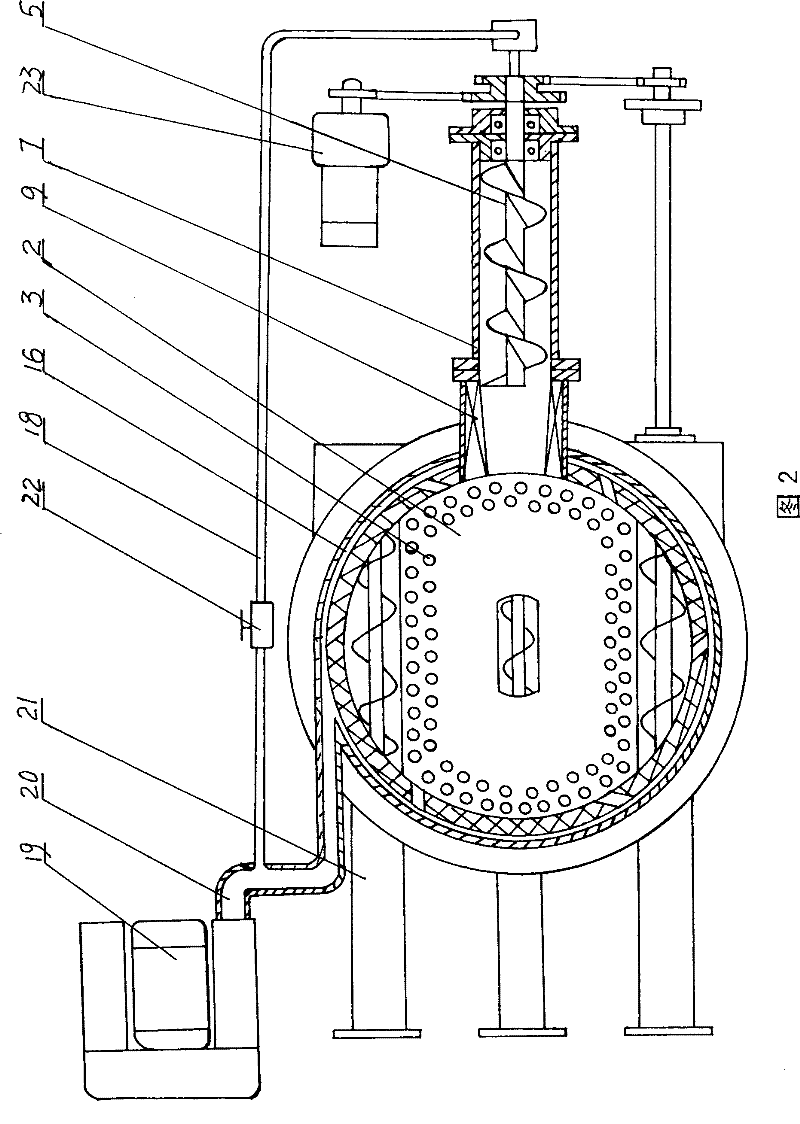

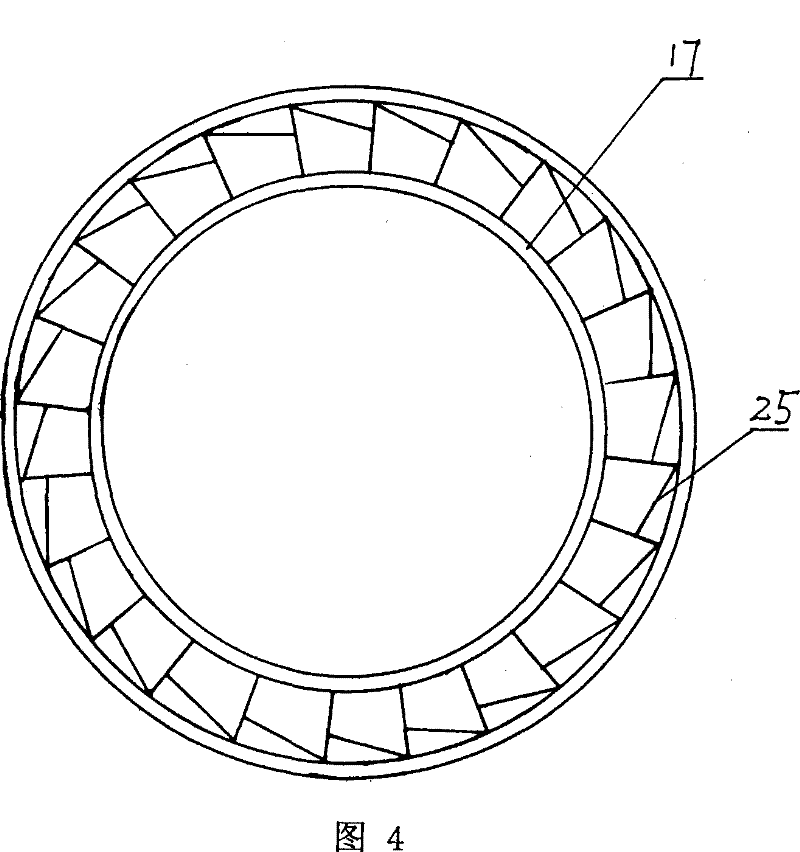

[0020] The present invention comprises furnace body 13, and inside furnace body 13 is combustion chamber 12, and the bottom of combustion chamber 12 is slag baffle plate 2 with ventilation hole 3, and the bottom outlet 1 of slag baffle plate 2 is slag discharge screw 21; Between the furnace wall 14 with ventilation holes 10 of the chamber 12 and the furnace body 13 shell 15 is a secondary air duct 16; the outlet of the combustion chamber 12 is a swirl nozzle 17 with spiral blades 25; An electric heater 9 is arranged at the place, and the electric heater 9 is connected with the delivery pipe 7 with the feed screw 5 inside and the fuel bin 6 on the top, and the ignition air duct 4 is arranged in the feed screw 5 .

[0021] The air pump 19 links to each other with the secondary air duct 16 through the pipeline 20;

[0022] For better slag discharge effect, three slag discharge screws 21 can be arranged at the bottom of the slag discharge baffle plate 2;

[0023] Outside the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com