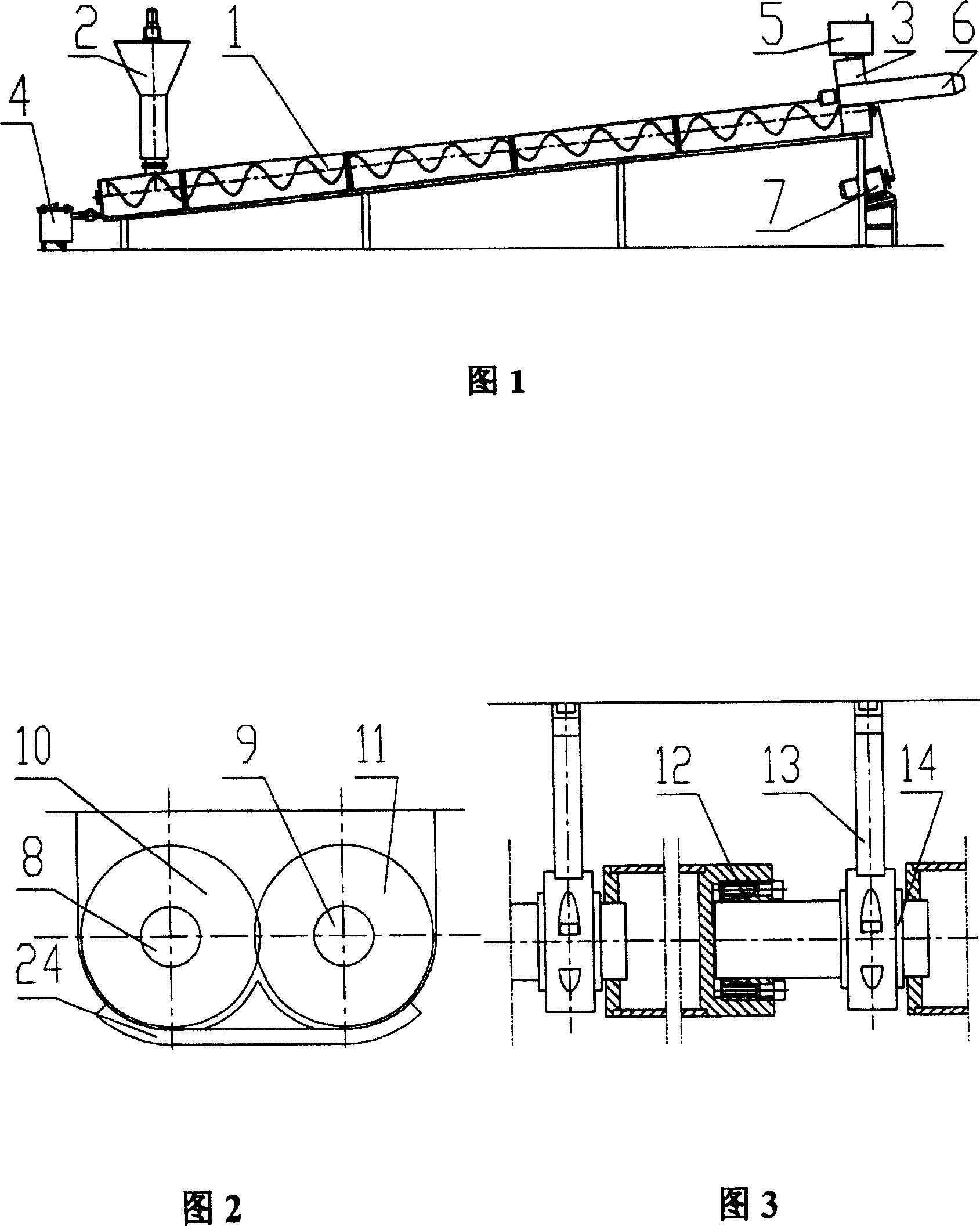

Double-spiral, continuous counter-flow extraction equipment

An extraction device and double-helix technology, applied in the field of continuous countercurrent extraction equipment, can solve the problems of difficulty in equipping auxiliary devices and mechanisms, high cost, and no practical application, etc., and achieve the effect of breaking through the length limit, large effective volume, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

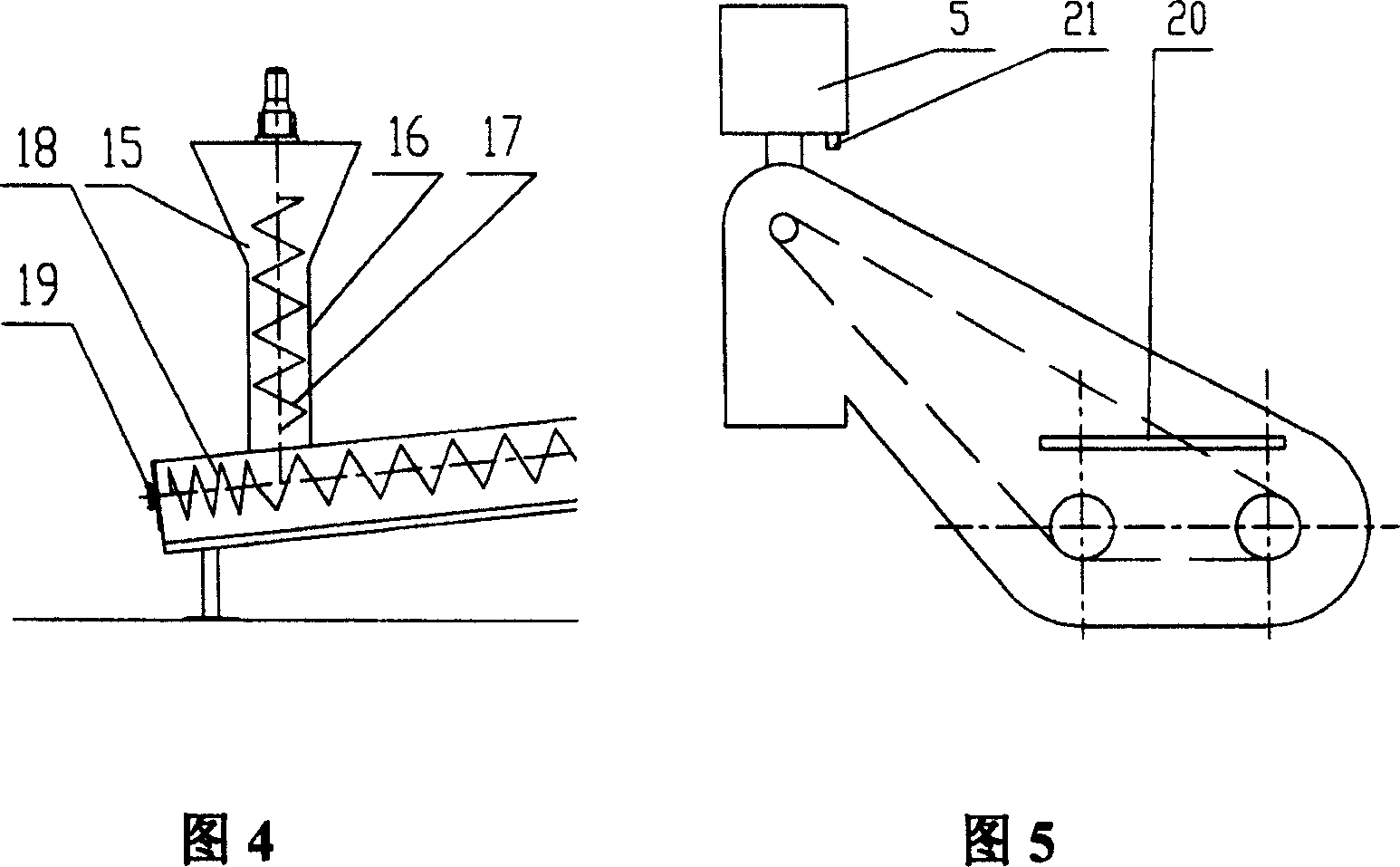

[0019] The obliquely placed leaching chamber of the present invention is designed with two side-by-side reverse screw shafts 8 and 9, with continuous screw blades 10 or intermittent paddles 11 covered with small holes; the screw shaft is composed of multiple sections, and the two screw shafts are connected The point is wrong, the inclined plane coupling 12 is connected with the upper wall frame of the leaching chamber by an adjustable and positioned connecting rod 13 to form a hanger. Taking a medium-sized equipment as an example to illustrate the implementation of the double-helix continuous countercurrent extraction device: the continuous countercurrent leaching chamber is placed at an elevation angle of 8 degrees, the center distance between the two helical shafts in the leaching chamber is 350mm, the outer diameter of the spiral blade is Φ400mm, the inner diameter of the main shaft is Φ89mm, and the pitch is 215mm , total length 12000mm.

[0020] How It Works and Benefits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com