High frequency induction heating screw extractor

A technology of high-frequency induction heating and high-frequency induction, which is applied in the field of pullers, can solve problems such as difficulty in disassembly, and achieve the effects of reducing equipment costs, reducing volume and weight, and novel structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

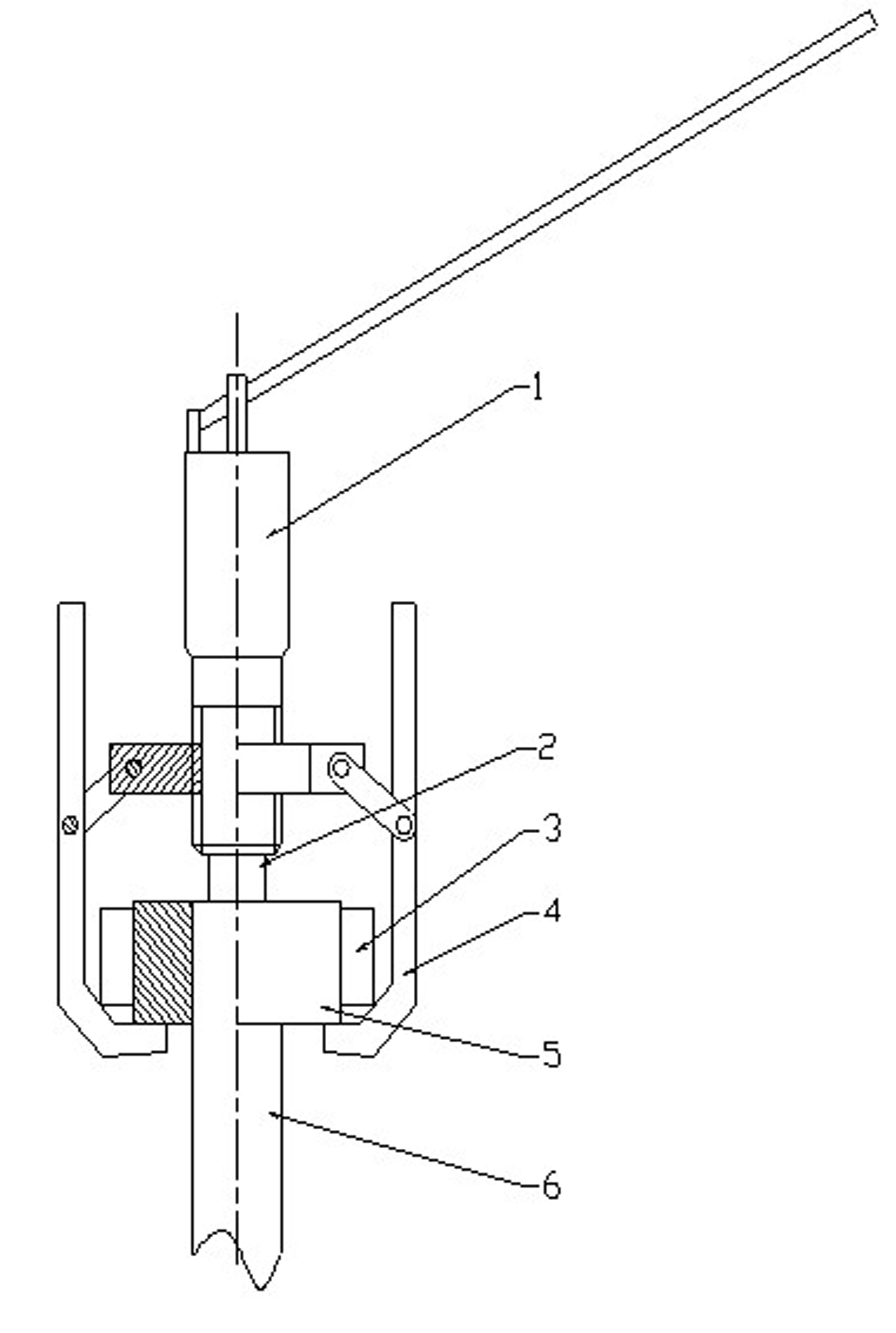

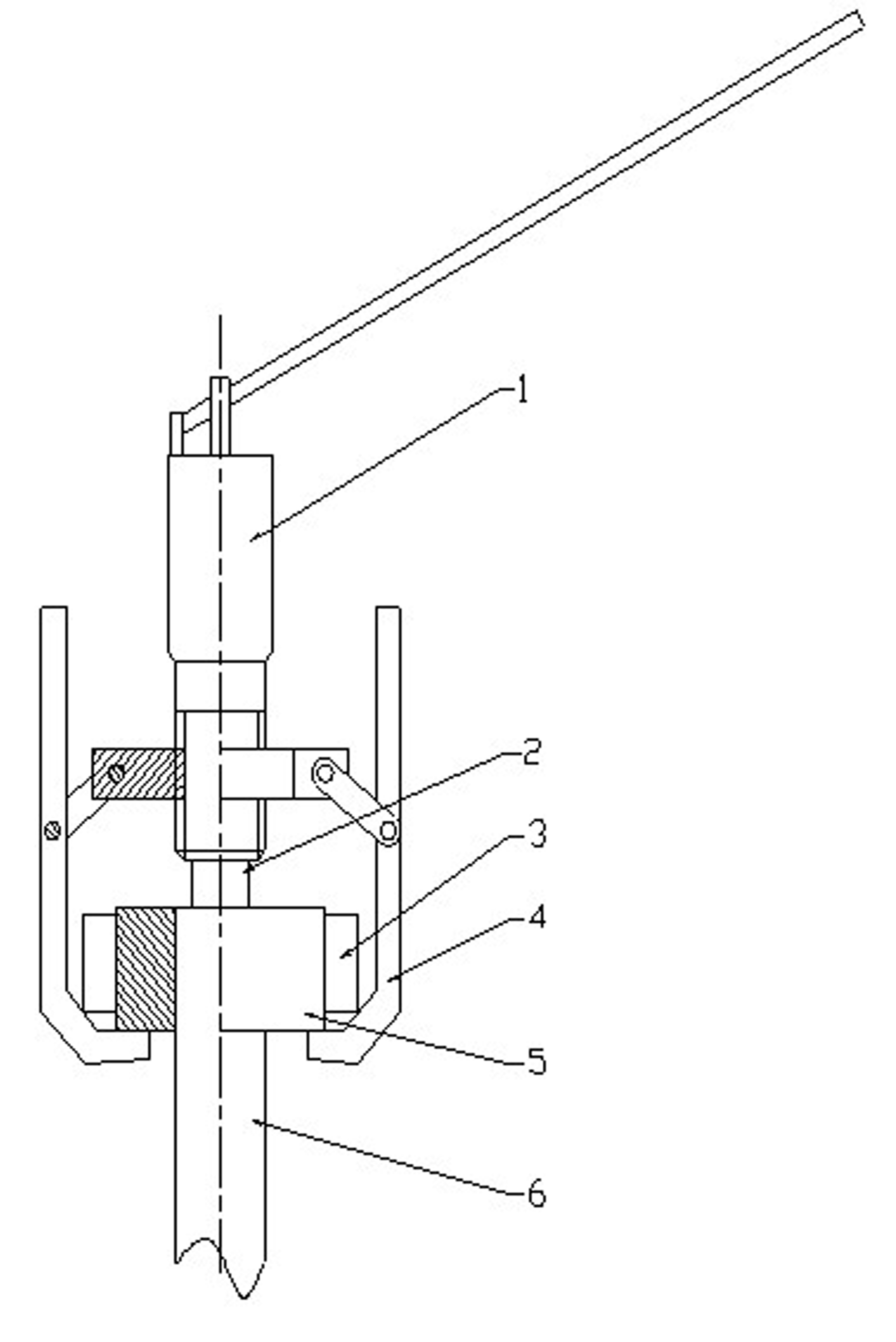

[0009] The high-frequency induction heating puller includes a top rod 2 and a hook 4 connected with the top rod 2, and also includes a set of high-frequency induction heaters 3, and one end of each high-frequency induction heater is equipped with a magnet. In this specific embodiment, the ejector rod 2 is in the form of a jack 1. The high-frequency induction heater 3 adopts existing products.

[0010] When in use, first adsorb the high-frequency induction heater 3 on the surface of the disassembled part 5. According to the size of the surface of the disassembled part or the requirements of the heating speed, adsorb a corresponding number of high-frequency induction heaters, and then install the puller On the disassembled part 5, properly push out the jack-type ejector rod 2 to properly pre-energize, and then connect the high-frequency induction current to quickly heat the outer surface of the disassembled part, and the shaft 6 of the disassembled part basically keeps the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com