Inner fixing screw extractor in orthopedics department

A technology for fixing screws and extractors, applied in the direction of fixators, etc., can solve the problems of soft tissue damage, breakage of reverse threaded drills, failure to occur, etc., and achieve the effects of good anti-shedding performance, enhanced occlusal force, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

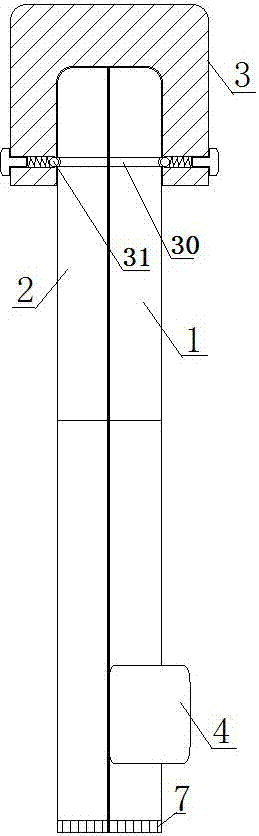

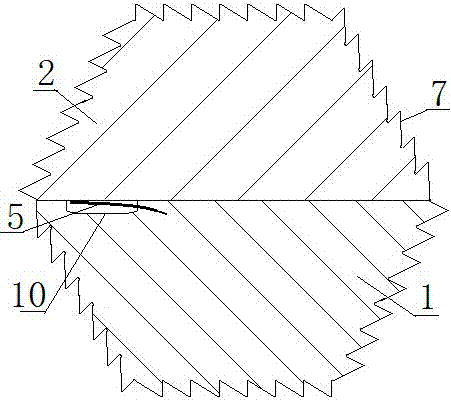

[0018] Embodiment one, such as figure 1 As shown in -3, the orthopedic internal fixation screw extractor of the present invention is a hexagonal (or six-pointed star) outer hexagonal (or hexagonal star) at the lower part and a cylindrical wrench at the upper part, which are made of tool steel and are made of tool steel with the same thickness (or thicker above the lower end) on the left and right. Cylinder, the upper end buckle is equipped with upper end cap 3 (or mutually hinged); the right flap of the outer hexagonal (or hexagonal star) wrench cylinder The lower part of the wrench cylinder 1 is fixed with a side extension handle 4 for rotation and force, and the right flap is The clockwise rear inner end surface of the lower end of the wrench cylinder 1 is equipped with a spring 5 for outwardly pressing the opposite inner end surface of the lower end of the left flap wrench cylinder 2 . Described spring comprises all springs such as helical spring, shrapnel type spring, elas...

Embodiment 2

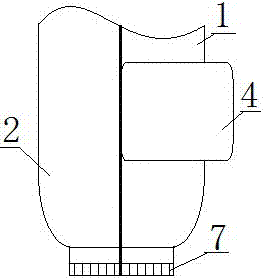

[0024] Embodiment two, such as Figure 4 As shown, the difference between the orthopedic internal fixation screw extractor of the present invention and the first embodiment is that the upper and lower ends of the left and right flaps of the wrench cylinder are simultaneously thickened into a circle, and the side extension handle 4 is fixedly mounted on the thickened lower portion of the right flap.

Embodiment 3

[0025] Embodiment three, such as Figure 5 As shown, the difference between the orthopedic internal fixation screw extractor of the present invention and Embodiment 1 is that the wrench cylinder is only fixed on the lower end of the right lobe of the side extension handle 4 and is thickened, and the side extension handle 4 is fixed on the thickened lower part of the right lobe. It can also be: the lower ends of the left and right petals of the wrench cylinder are symmetrical two petals that are evenly divided on the left and right, the large part of the thickened part is the right petal with a handle, and a small part of the thickened part is the left petal. About 2 / 3 of the area of the thickened part is the right lobe with handle, and about 1 / 3 of the area of the thickened part is the left lobe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com