Broken-end screw taking-out device

A technology for extractors and screws, applied in the field of extractors, can solve the problems of complex operation, waste of manpower and material resources, and high technical requirements for operation, and achieve the effect of convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

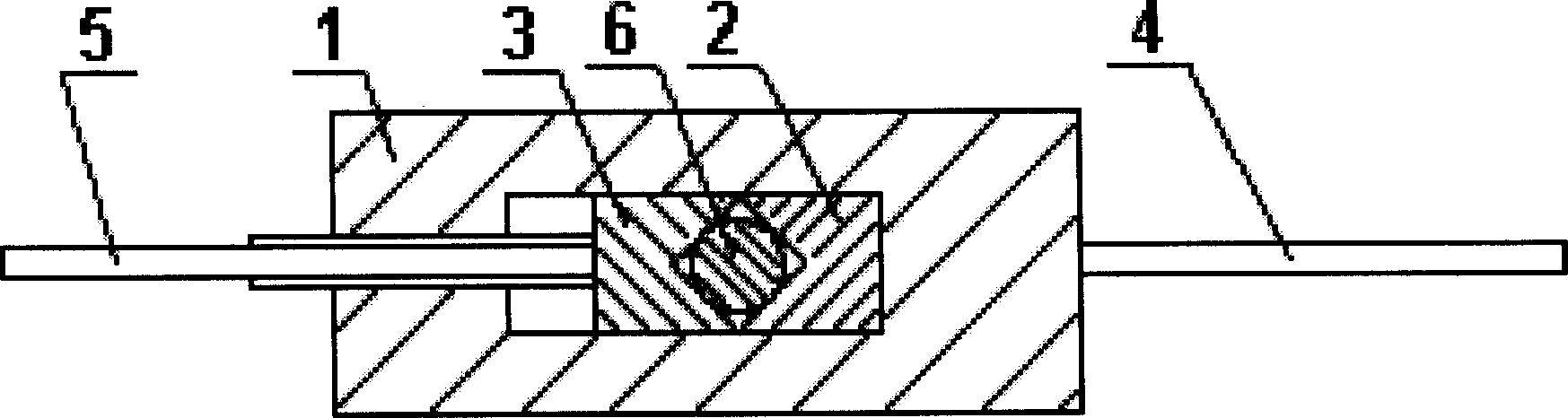

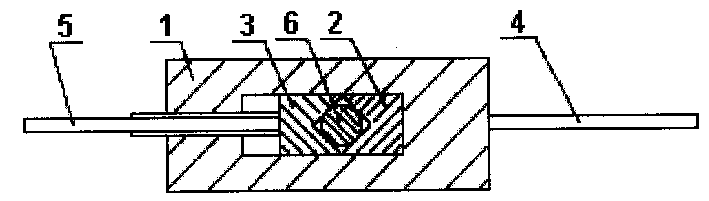

[0007] Such as figure 1 As shown, the screw extractor of the present invention is composed of a clamping frame 1, a fixed clamping die 2, a movable clamping die 3, a fixed rod 4, a movable rod 5 and a threaded rod 6. The middle part of the clamping frame 1 A rectangular hole is provided, the fixed clamping die 2 is arranged in the rectangular hole of the clamping frame 1, and the outer wall of the fixed clamping die 2 is connected to the outer wall of the rectangular hole of the clamping frame 1 , the specific connection method can be welded connection, the movable clamping die 3 is also arranged in the rectangular hole of the clamping frame 1, the outer wall of the movable clamping die 3 and the clamping frame 1 The outer walls of the rectangular holes are in contact with each other, and the fixed clamping die 2 and the movable clamping die 3 are provided with clamping openings, the clamping openings can be parallelograms, the fixed rod 4 and the The clamping frame 1 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com