Air suction type drill bit with replaceable blades used in CFRP drilling

A drill bit and blade technology, which is applied in the field of suction drill bit for CFRP drilling, can solve the problems affecting the strength and fatigue life of the carbon fiber composite material connection structure, affecting the health of workers, the service life of the tool, and failing to realize the automatic recycling of chips, etc. , to achieve the effect of lowering the temperature, reducing the processing cost, and suppressing the occurrence of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

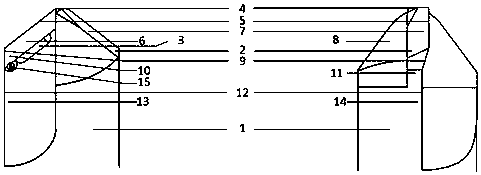

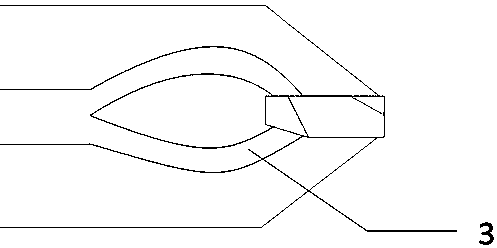

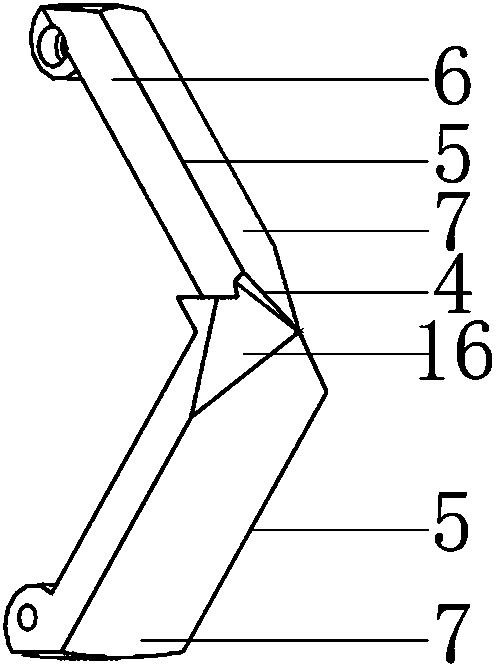

[0021] This paper designs a welded insert for CFRP drilling to reduce defects during CFRP processing. The insert mainly includes: 1-drill body, 2-blade, 3-suction channel, 4-chisel edge , 5-main cutting edge, 6-main rake face, 7-first main flank face, 8-second main flank face, 9-first auxiliary cutting edge, 10-first auxiliary rake face, 11 -First flank, 12-Second cutting edge, 13-Second rake face, 14-Second flank, 15-Screw, 16-Cut at chisel edge.

[0022] 2-The blade can be replaced, and it is connected to the 1-drill body through 15-screws; 6-The rake angle of the main rake face is positive, which can improve the processing quality; 3-The hole is connected to the negative pressure generating device outside the drill body, and the chips are mainly Generated at the 6-rake face, when the negative pressure is generated, the chips pass through the 3-suction channel near the 2-drill body to the outside and are absorbed by the chip absorbing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com