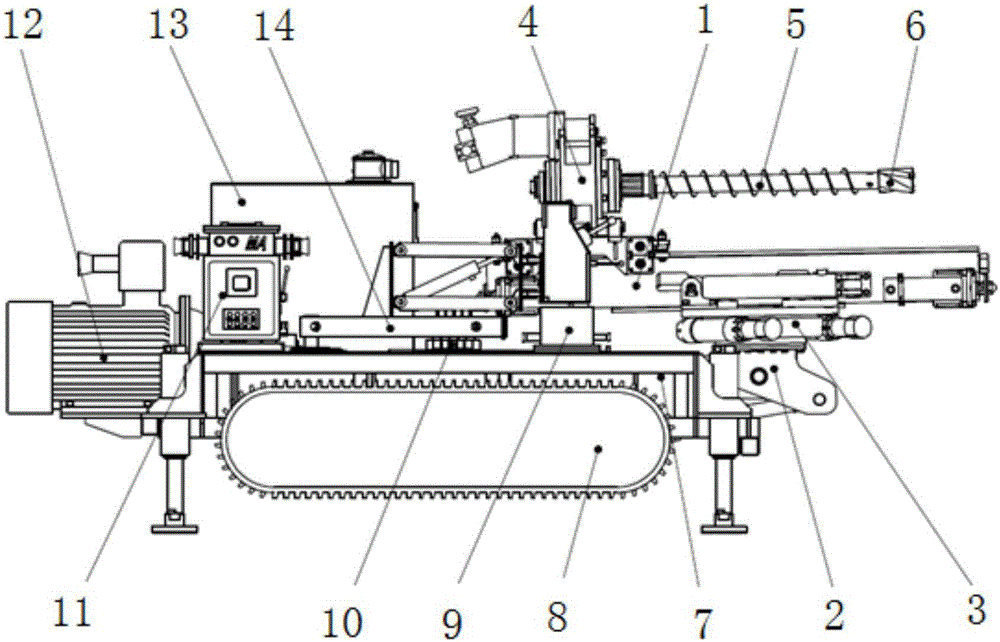

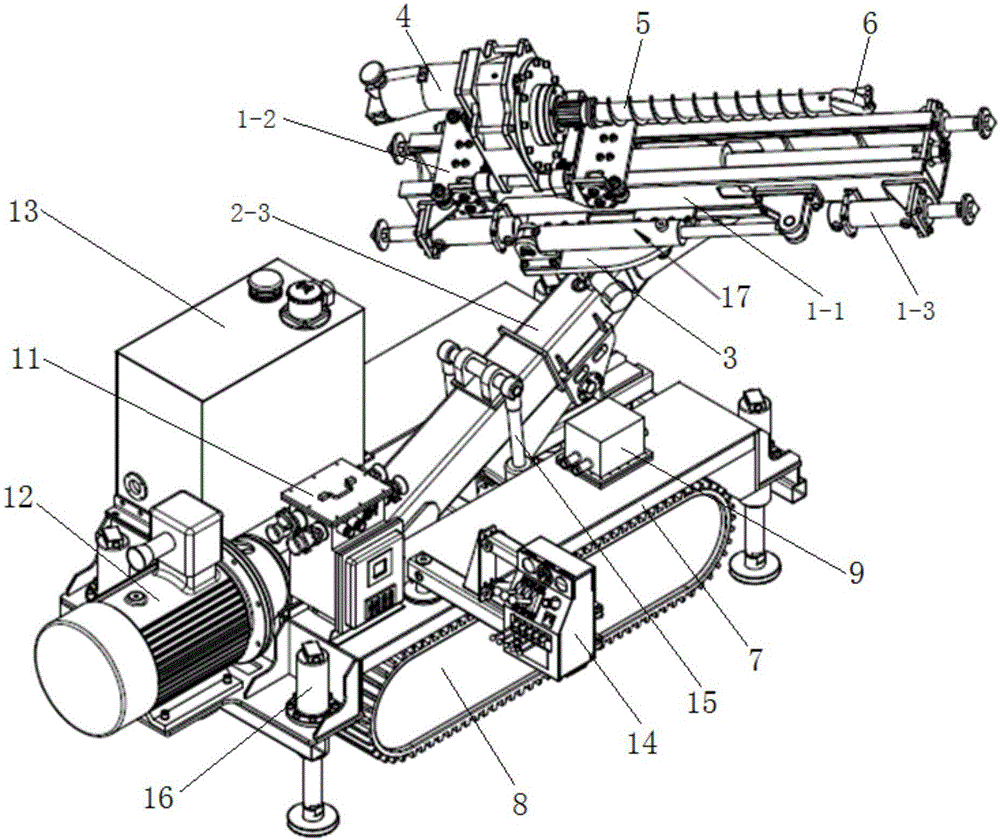

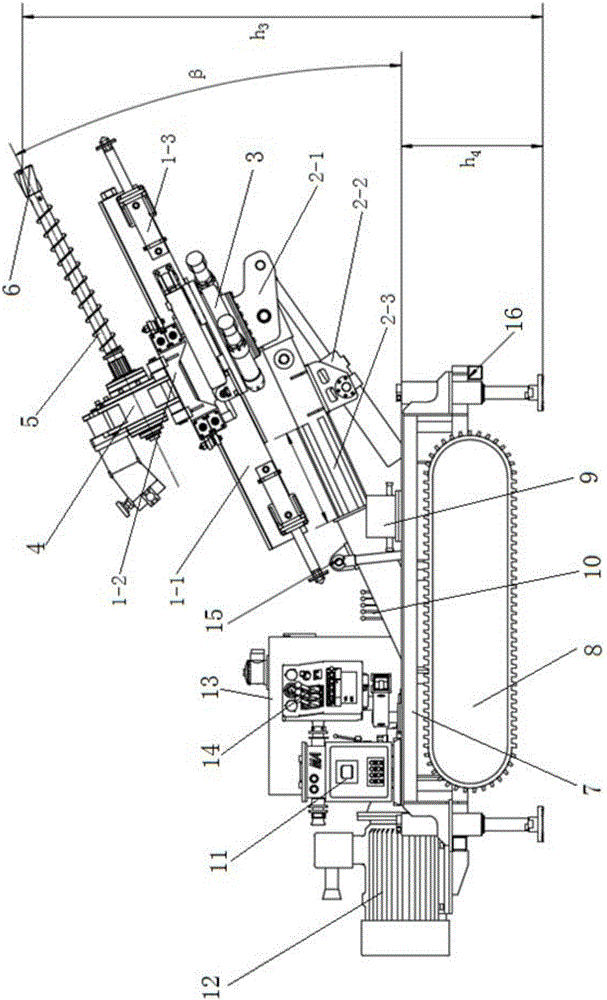

Omnibearing longhole drilling machine

A deep hole drilling rig, all-round technology, applied in the direction of earthwork drilling, drilling equipment, drilling equipment and methods, etc., can solve the problems of increased walking resistance, poor stability, and inability to support the mast at all angles, reaching the diameter of the oil cylinder The effect of reducing and propulsive resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The first omni-directional deep hole drilling rig of the present invention comprises a frame, crawlers and leg cylinders are installed under the frame, hydraulic pumps, oil tanks and operating components are installed on the frame, and luffing units, Rolling friction unit and drilling rig unit; the non-oscillating end of the luffing unit is fixed on the frame, the rolling friction unit is set on the swinging end of the luffing unit, and the drilling rig unit is set on the rolling friction unit, and the rolling friction unit can be adjusted through the luffing unit And the drilling unit swings within the range of 0-105°, and the rolling friction unit can drive the drilling unit to roll along its axial direction.

[0052] The second omni-directional deep hole drilling machine of the present invention can also be based on the first one, and a rotary unit is also provided between the luffing end of the luffing unit and the rolling friction unit, and the rotary unit can drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com