Tri-tube tri-high-pressure jet grouting pile construction method

A technology of high-pressure rotary grouting piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large soil squeezing effect, small pile diameter, and low work efficiency, so as to reduce the soil squeezing effect, Effect of reducing impact and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

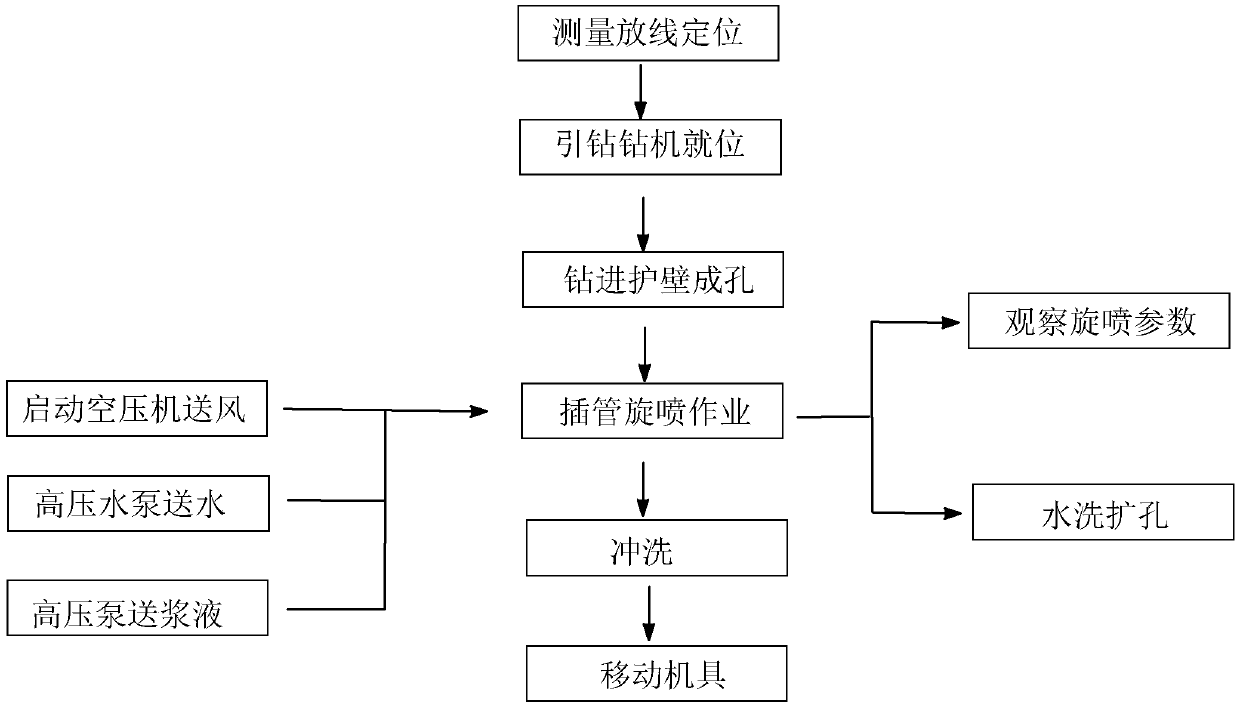

[0044] An embodiment, a construction method of a triple-tube triple-high-pressure jet grouting pile, is specifically described as follows.

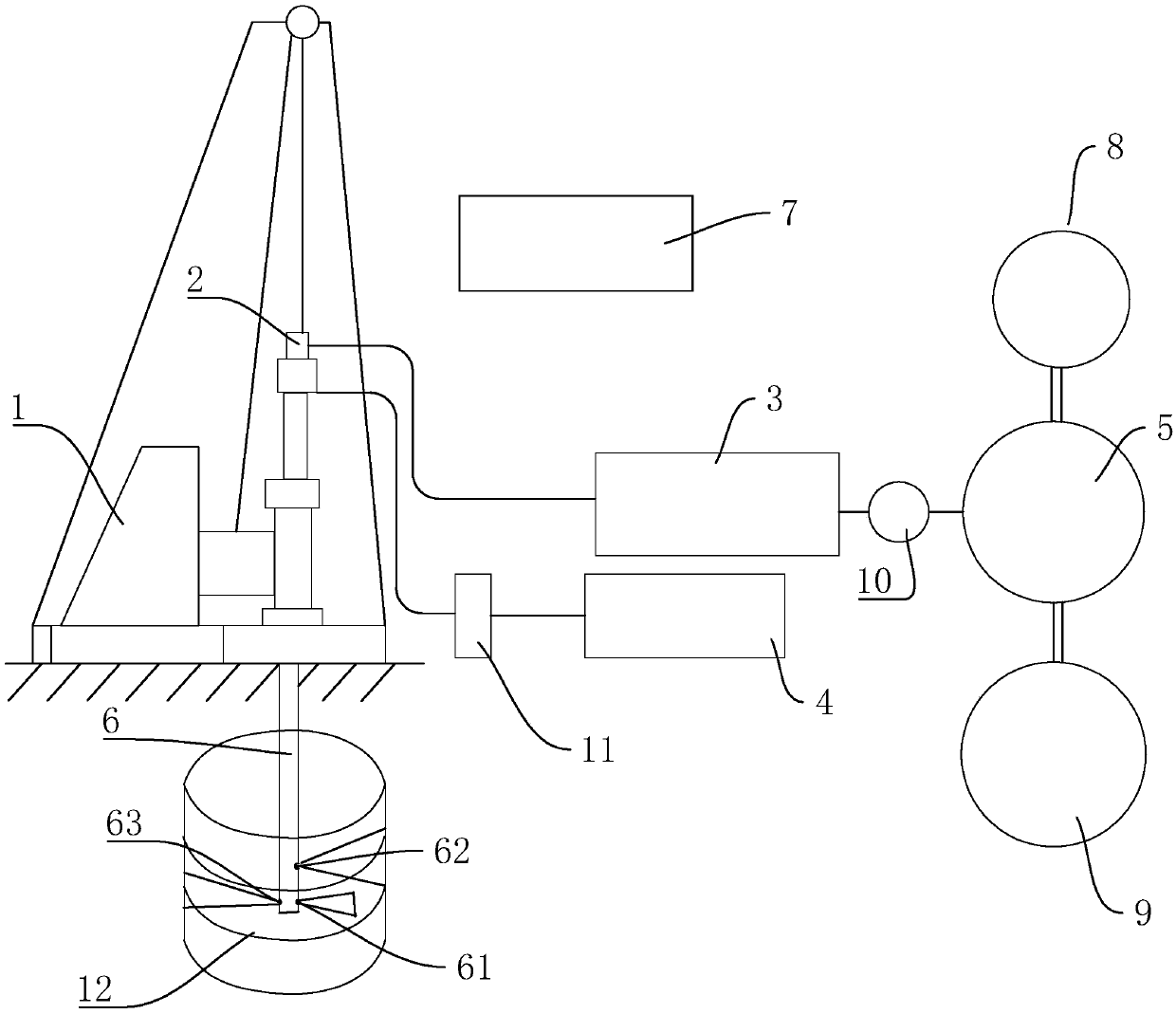

[0045] Such as figure 1 As shown, the main equipment involved in this method includes a model of 300-shaped drilling rig 1, a model of PH-5A triple tube three high-pressure rotary spraying trolley 2, a high-pressure mud pump 3, an air compressor 4, a mortar mixer 5, and a spraying machine. Grouting pipe 6, high-pressure water pump 7, water tank 8, cement silo 9, slurry bucket 10 and gas meter 11. Wherein water tank 8 is connected with cement silo 9 and mortar mixer 5, thereby is used for preparing cement slurry. The mortar prepared in the mortar mixer 5 is sent into the mortar barrel 10 for storage and standby. During rotary grouting, the high-pressure mud pump 3 pumps it into the triple-tube three-high-pressure rotary grouting trolley 2, and injects it into the borehole through the multi-section jet grouting pipe 6 to form a consolidate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com