Slurry injection technique of sleeve valve tube of cloth bag

A sleeve valve pipe grouting and sleeve valve pipe technology, which is applied in the direction of soil protection, sheet pile walls, construction, etc., can solve the problems affecting the construction quality, reduce the effect of soil squeezing, avoid grouting, and increase the strength of foundation soil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

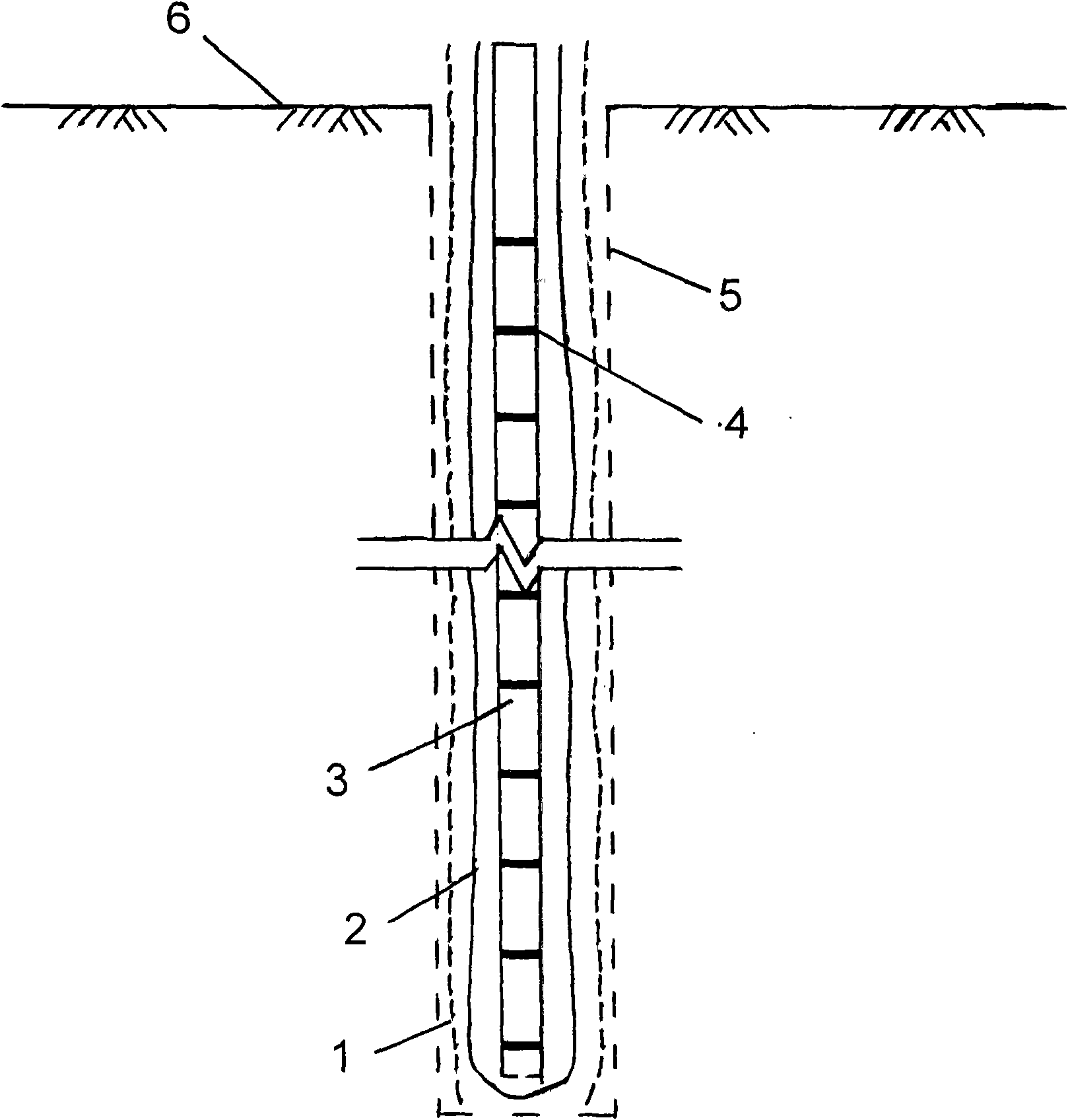

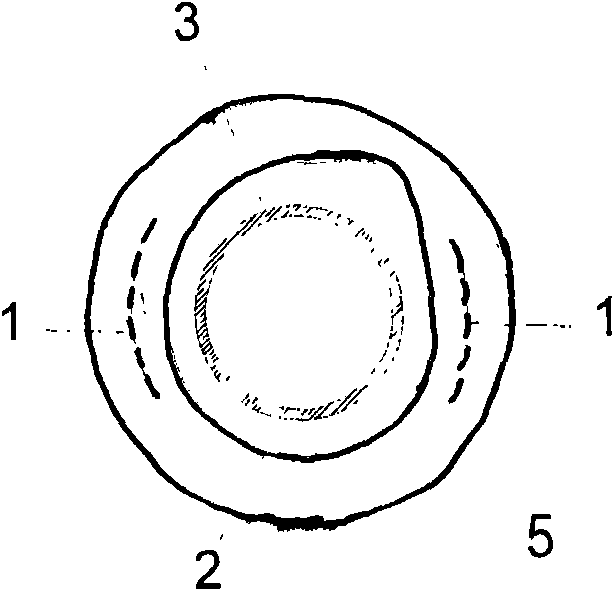

[0018] Such as figure 1 The schematic diagram of the sleeve valve pipe shown in the figure is to make a cloth bag sleeve valve pipe. Use geological drilling rigs and other equipment to drill a hole with a diameter of not less than 10cm, and insert the sleeve valve pipe installed with a cloth bag and a plastic drainage board into the drill hole. The cloth bag can be made of geotextile. Wait for production, fix 1 to 2 plastic drainage boards along the depth direction on the outside of the cloth bag, and temporarily fix the cloth bag and plastic drainage boards on the sleeve valve pipe every 0.5m with adhesive tape; and take measures to prevent the cloth bags and plastic drainage boards from sinking into the holes Inside; pour the casing material into the cloth bag, pour the casing material from the bottom of the hole upwards, and use the iron wire to close the bag opening after the pure casing material flows out from the hole, and continue to pour the casing material to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com