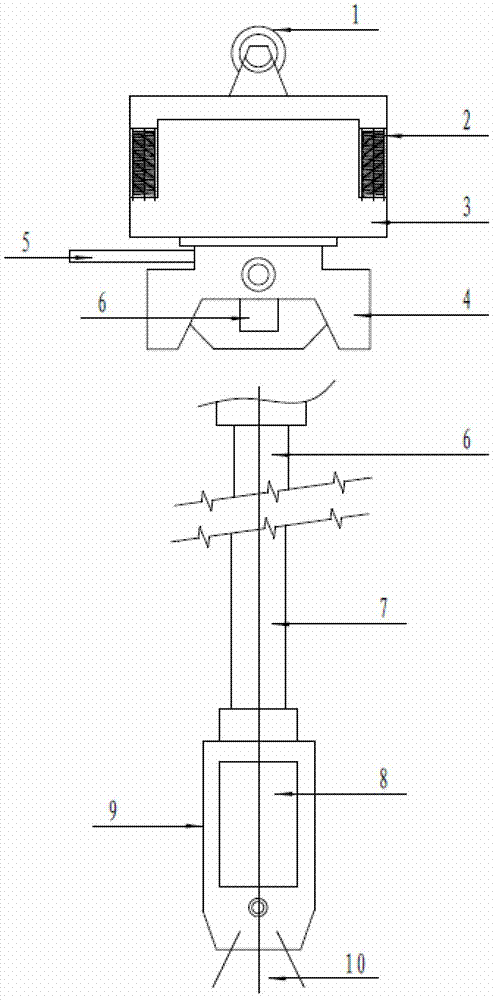

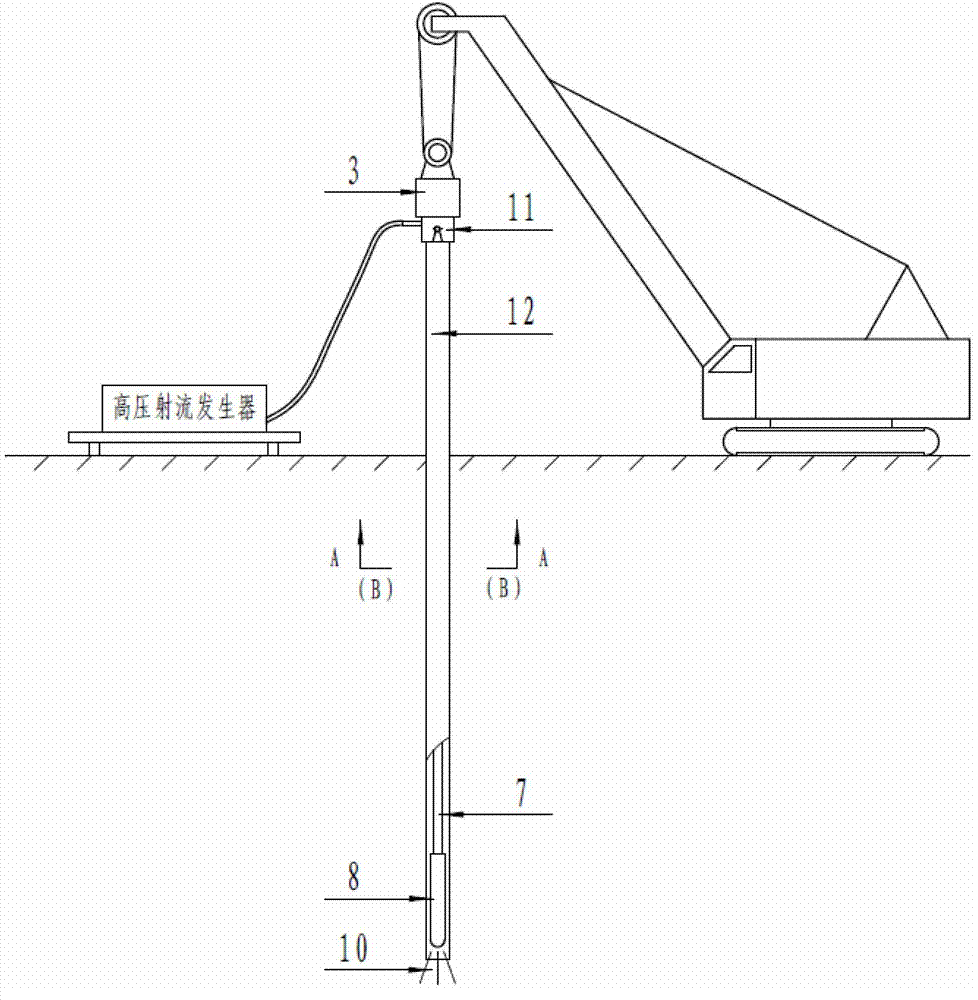

High-pressure spray pile vibrosinking device and process

A high-pressure jet and vibratory pile sinking technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as sinking, difficult pile ends, and limited applicability of reinforced concrete prefabricated piles, so as to improve bearing capacity, Effects of reducing engineering cost, widening pile sinking conditions and application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] When used in a hollow pile, the jet tube 7 and the horizontal exciting force generator 8 can be put into the through hole of the hollow pile, and the pile sinking construction is carried out synchronously with the high-pressure jet, wherein the jet tube 7 and the horizontal exciting force generator 8 can be It can be made into one set, or it can be made into multiple sets;

Embodiment 2

[0041]When used for solid piles and various special-shaped piles, multiple sets of jet tubes 7 and horizontal excitation force generators 8 can be fixed with a frame according to the shape of the pile body to form a fixed structure similar in shape and size to the pile body itself. During this process, the above-mentioned fixed structure is first sunk to a predetermined depth at the position of the pile sinking, and then the fixed structure is pulled out, and then the pile is sunk to a predetermined depth.

[0042] In actual use, depending on the technical requirements of different types of engineering design piles and the specific complex conditions of engineering geological strata, the ground and underground parts can be used separately or in combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com