Slurry injection technique of double-valve sleeve valve tube of cloth bag

A sleeve valve pipe grouting and sleeve valve pipe technology is applied in soil protection, sheet pile walls, construction and other directions, which can solve problems such as long construction period, shorten construction time, save costs, and reduce the effect of soil squeeze.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

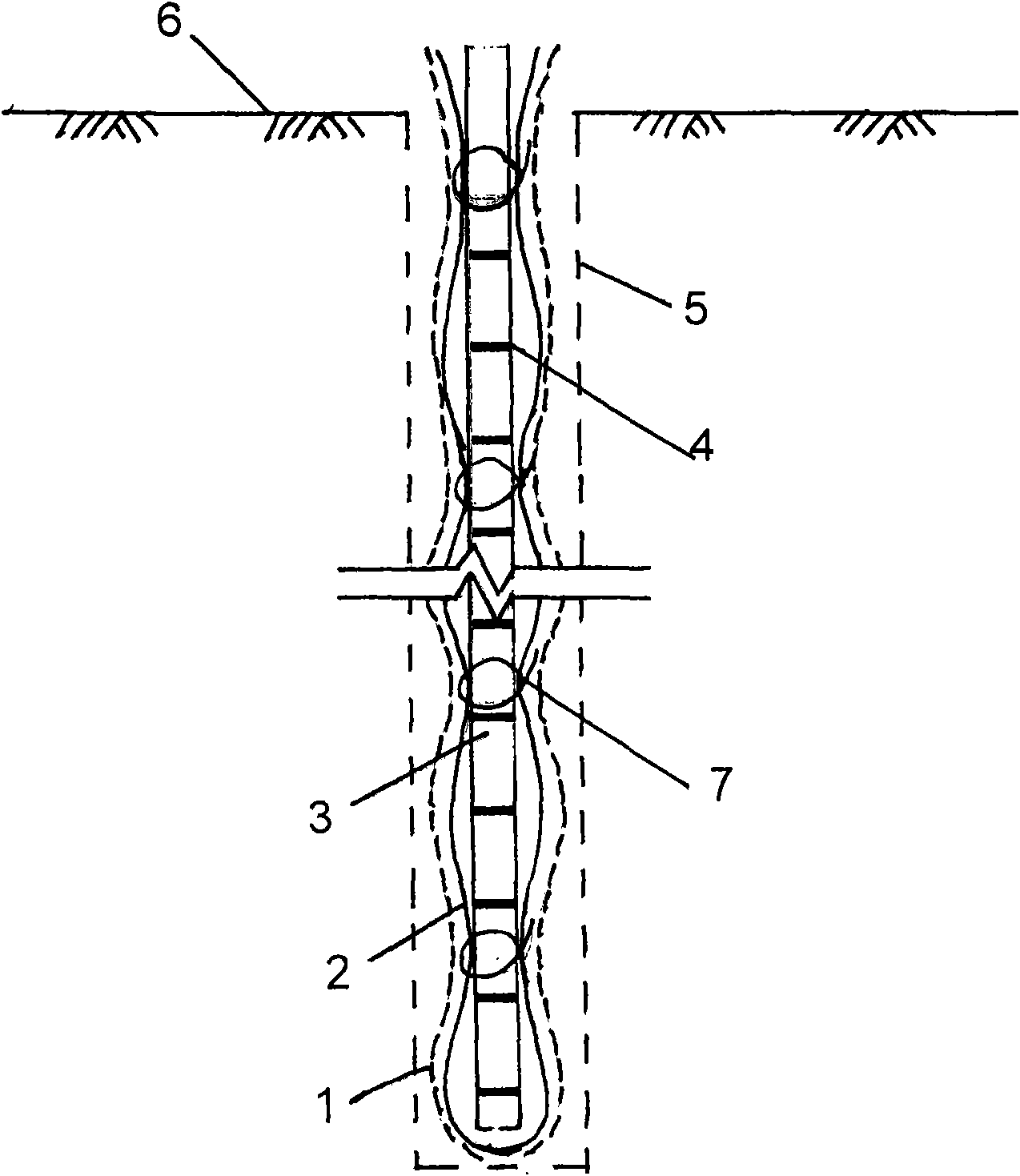

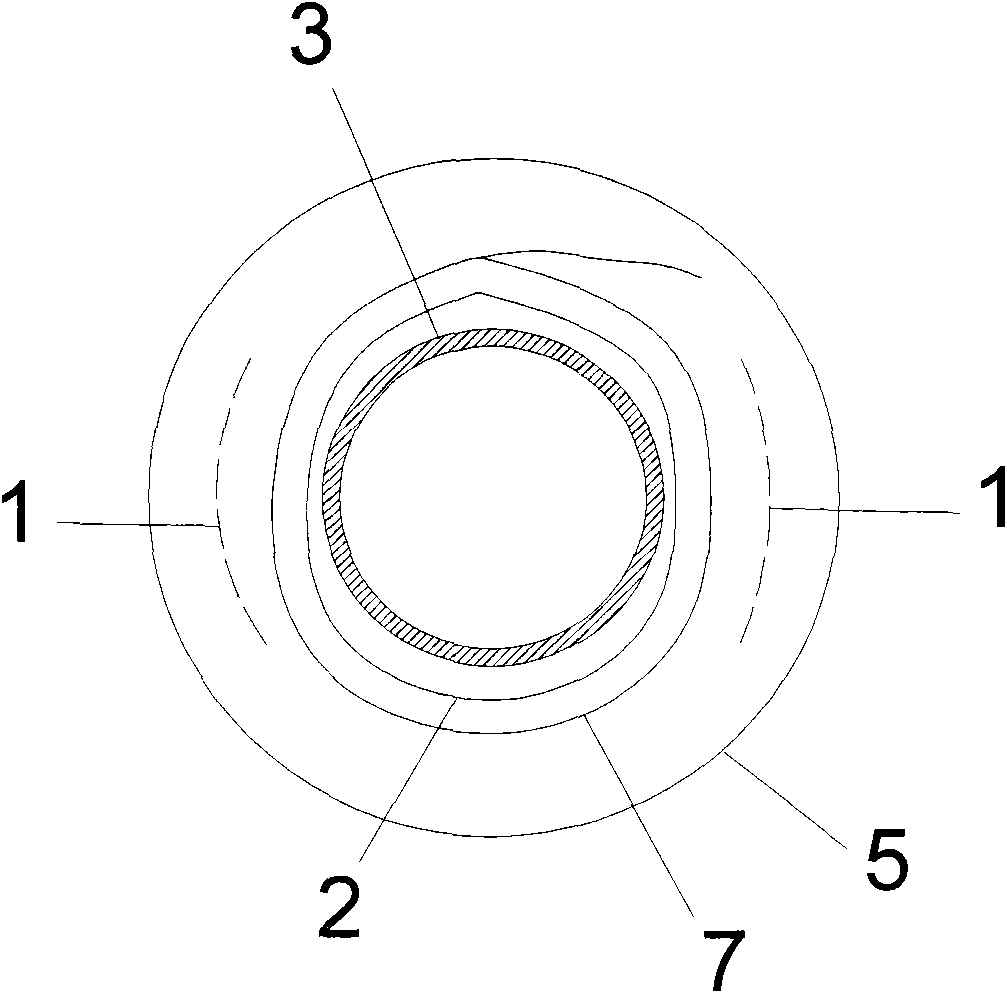

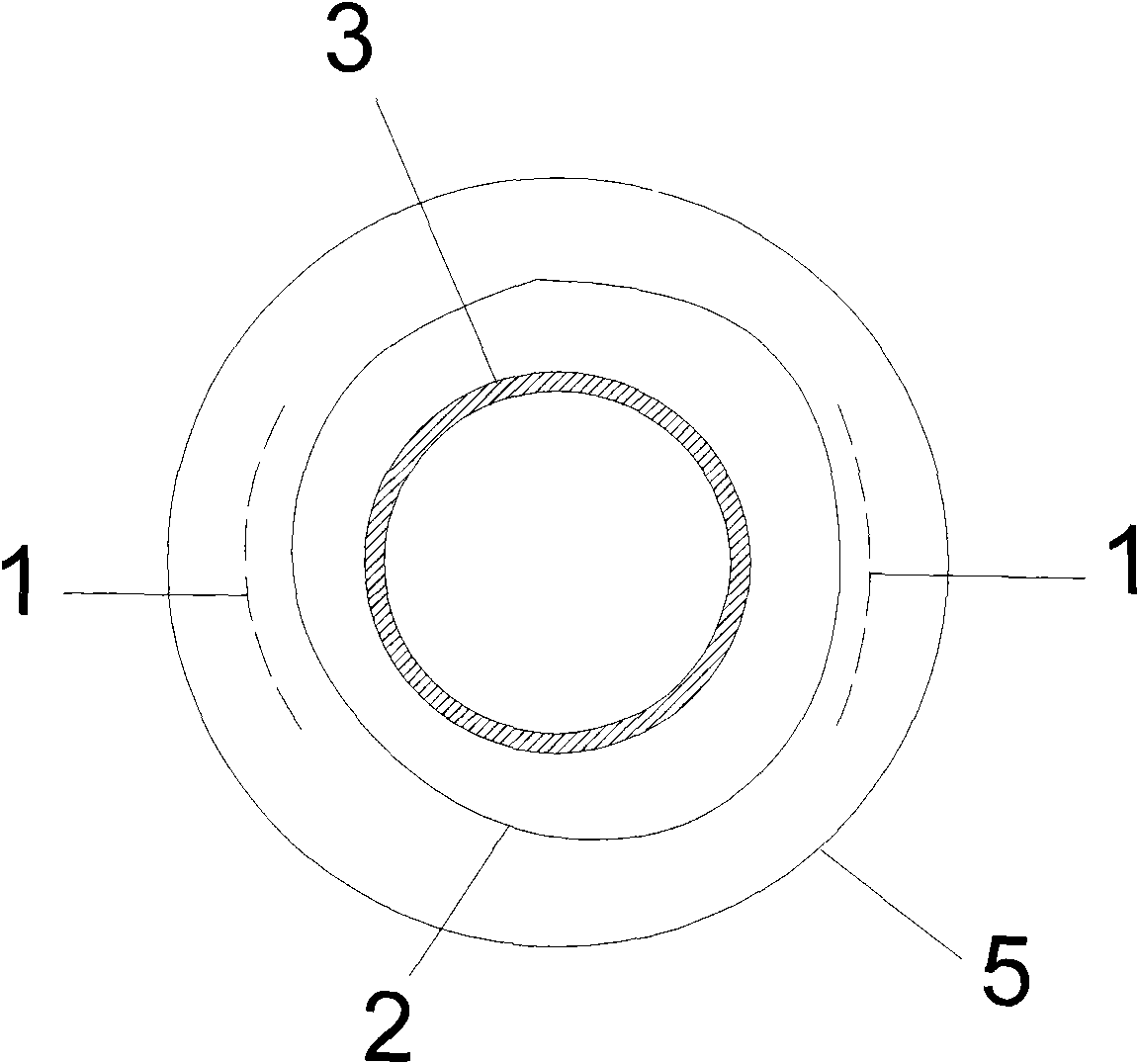

[0023] (1) Making double-valve cloth bag sleeve valve tube: such as figure 1 As shown in the schematic diagram, use geotextiles to sew a cloth bag with the same length as the sleeve valve pipe, and its volume is 0.6 to 0.9 times the grouting volume. The tensile strength and suture strength of the cloth bag should be greater than 15kN / m. Put the cloth bag on the sleeve valve pipe, and use plastic buckles to firmly bind the cloth on the sleeve valve pipe every 1.5-2m. The plastic buckle must not be opened before the designed grouting pressure is reached. Fix 1 to 2 drainage boards on the cloth bag by pasting or other methods, and the drainage boards are arranged symmetrically.

[0024] (2) Grouting construction: use geological drilling rigs and other equipment to drill a hole with a diameter of not less than 10cm, insert the double valve pipe into the hole, and use the same grouting equipment as the sleeve valve pipe for grouting, that is, use grouting Grout gun for grouting. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com