A foundation treatment method of permeable pile combined with vacuum preloading

A technology for foundation treatment and permeable piles, which is applied in infrastructure engineering, construction, soil protection, etc., can solve the problems of high cost of long-distance transportation of stacking materials, easy blockage of plastic drainage boards, and difficult construction quality control, etc. The effect of soil consolidation settlement, accelerated consolidation speed, high stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

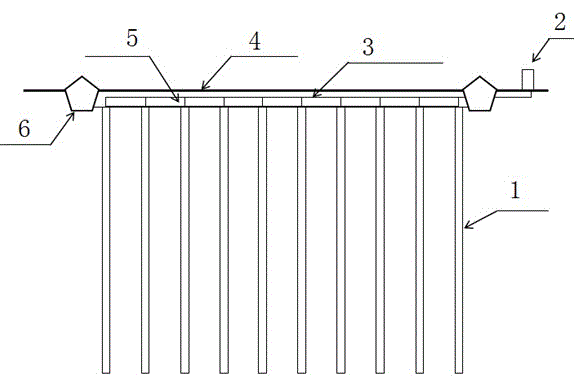

[0029] Step (1) Prepare the permeable pile 1. The pile body is a hollow pipe pile with a pile cap, which is permeable and breathable; the strength of the pile body is 15MPa-30MPa, and the permeability coefficient is 0.01mm / s-5.4mm / s. The diameter is 350-600 mm, the thickness of the pile wall is 100-200 mm, and the length of the pile body is 10 m-20 m.

[0030] Step (2) Divide the treatment area of the foundation into blocks, each block is divided by 3×104 m2 to 4×104 m2, and 6 to 8 adjacent single blocks form a block, and each block is constructed simultaneously during vacuum preloading, and each block Pipeline operation is carried out in between.

[0031] Step (3) Drive the prefabricated permeable piles into the foundation of the pre-compression area with a spacing of 1.2-1.5 m. The pile caps are not covered first, but covered with geotextiles. The sand cushion is fully paved in the pre-pressing area, with a thickness of 50 cm to 80 cm, mainly medium-coarse sand (mud conte...

specific example 1

[0037] A port soft foundation treatment project requires land reclamation to expand the port area, and build a container yard after the foundation bearing capacity meets the requirements. The land reclamation project was built by dredging reclamation on the original basis of the coast. The geological conditions from top to bottom are plain fill, dredger fill, sand with silt, silty clay with gravel, and argillaceous sandstone. The layer is thicker, resulting in a wide range of soft foundation treatment and great difficulty, making it difficult to control the overall investment. Therefore, in order to shorten the construction period and reduce the post-construction settlement, permeable piles combined with vacuum preloading can be used to treat the marine soft soil foundation.

[0038] The permeable piles are arranged with tubular piles, the length of which is 10 m to 20 m, the compressive strength of the piles is not less than 15MPa, and the permeability coefficient is not less...

specific example 2

[0043] For a coastal road project, the foundation is composed of crushed rock fill and dredged silt on the upper layer (land reclamation half a year ago) and the lower layer of silt-containing sand and argillaceous shale weathering products. It is a typical weak foundation. The water content of the foundation is Large, high compressibility, low strength, poor permeability, and inhomogeneity, so permeable piles combined with vacuum preloading can be used to treat the foundation.

[0044] The permeable piles are arranged with tubular piles, the length of which is 10 m to 20 m, the compressive strength of the piles is not less than 15MPa, and the permeability coefficient is not less than 0.01mm / s. Divide the foundation reinforcement area, each block is divided into 3×10 4 m 2 ~4×10 4 m 2 Carry out division, and form an area with 6 to 8 adjacent single blocks. The pile body is pressed into the foundation by a pile driver, and the sand cushion layer is fully spread in the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com