A kind of open high-strength concrete prefabricated pile and its pile form, centrifugal manufacturing method

A technology of high-strength concrete and prefabricated piles, applied in molds, sheet pile walls, buildings, etc., can solve the problems of poor bending resistance of the pile body and the effect of hard-pressed piles to squeeze the soil, and achieve fast pile-making speed, fast forming speed, Small footprint for pile making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

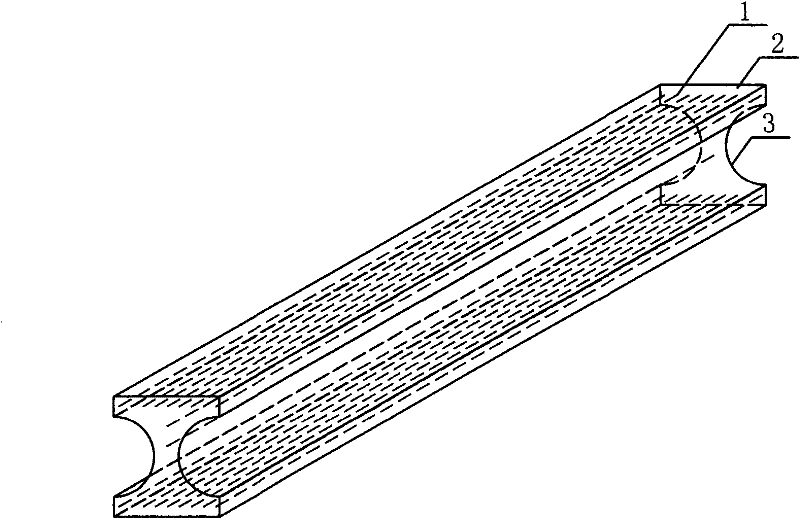

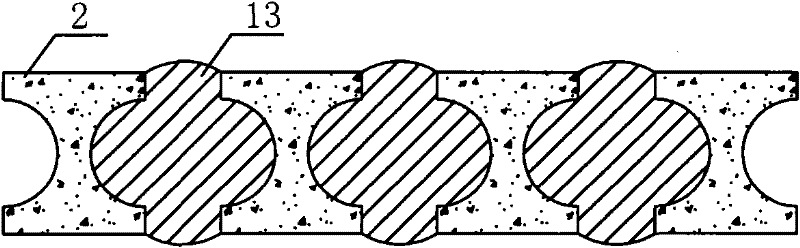

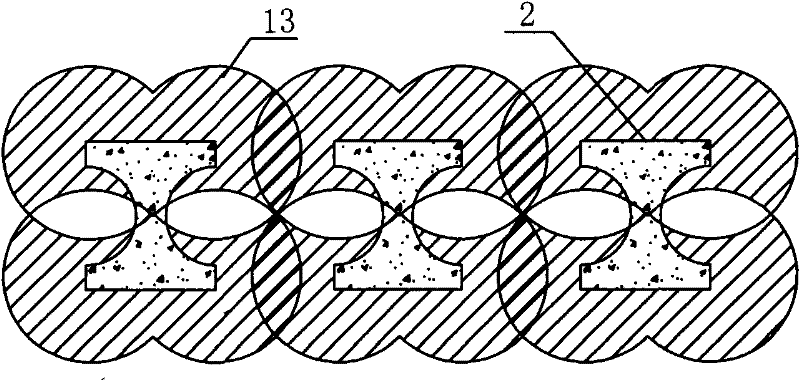

[0048] As the present invention such as Figure 1 to Figure 5 The first embodiment shown is mainly aimed at introducing the shape and structure of the open high-strength concrete prefabricated pile. Such as figure 1 As shown, the open high-strength concrete prefabricated pile of the present invention comprises a prestressed steel strand (1), a high-strength concrete prefabricated pile body (2) wrapped in the outside of the prestressed steel strand (1), in the present embodiment, in There are such as figure 1 The side shown has a centrifugally formed concave surface (3) with an arc-shaped cross-section. figure 1 The cross-sectional shape of the open high-strength concrete prefabricated pile shown is approximately H-shaped, which is a high-strength concrete H-shaped pile. The two ends of the high-strength concrete H-shaped pile introduced in this embodiment can be set as figure 2 The shown end plate (4), the end plate (4) can be made of a steel plate with a thickness of 20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com