Automobile part quenching device

A technology for auto parts and quenching devices, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of oil fume emission, poor condensation effect of condenser, excessive adhesion of oil fumes, etc., and achieve environmental protection and energy saving in driving mode Production cost, effect of guaranteed treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

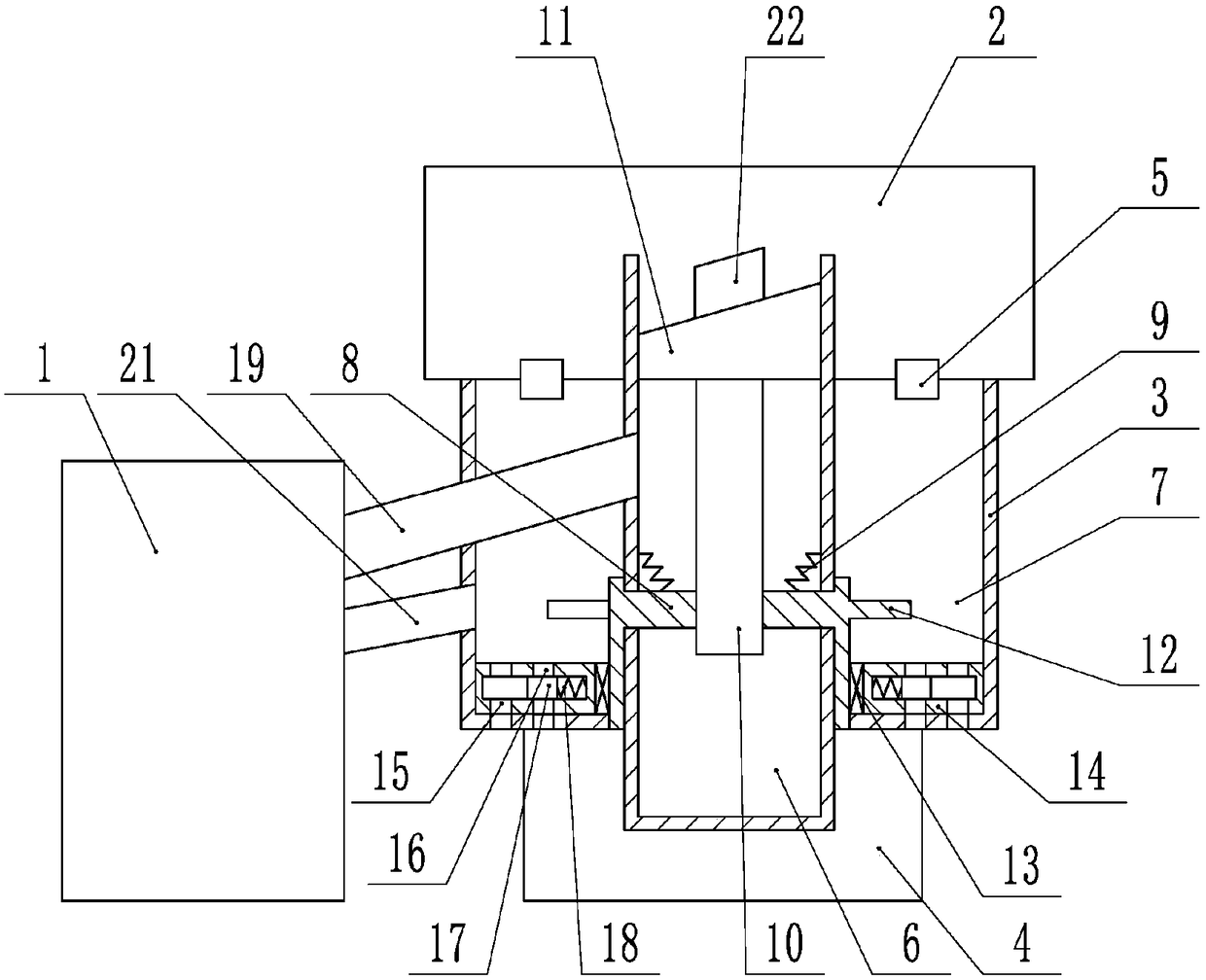

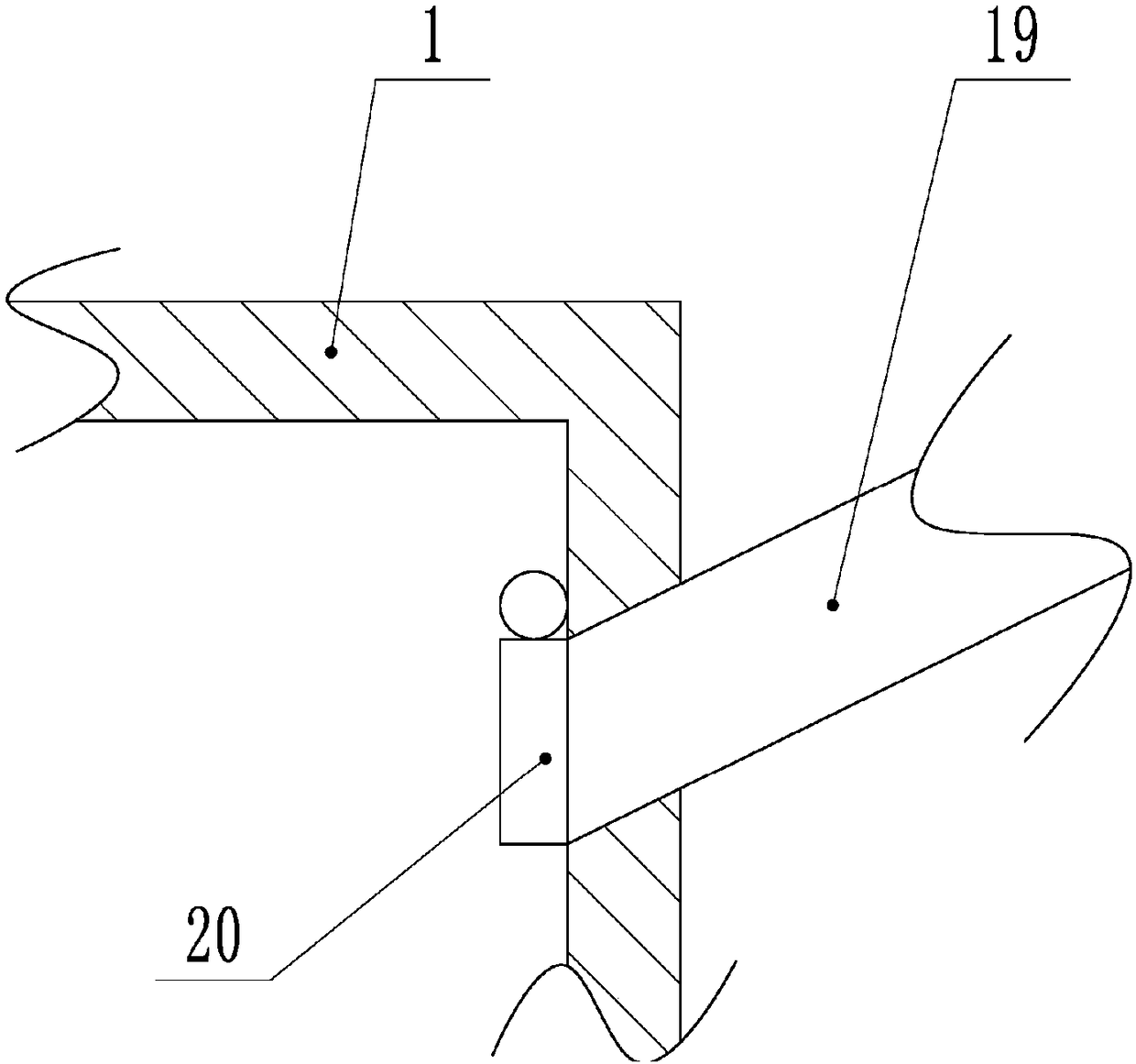

[0020] The reference signs in the drawings of the specification include: quenching box 1, heating box 2, air intake box 3, flue gas treatment box 4, solenoid valve 5, slideway 6, air inlet 7, turntable 8, first torsion spring 9 , screw 10, workpiece table 11, paddle 12, one-way bearing 13, gas distribution plate 14, air inlet 15, air outlet 16, valve core 17, spring 18, workpiece discharge groove 19, rotating plate 20, smoke exhaust pipe 21. Workpiece 22.

[0021] Such as figure 1 and figure 2 As shown, the quenching device for auto parts includes a quenching box 1 and a heating box 2 connected sequentially from top to bottom, an air intake box 3 and a flue gas treatment box 4. The connection between the heating box 2 and the air intake box 3 is installed with two A solenoid valve 5, a sleeve is installed in the air intake box 3, the sleeve divides the air intake box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com