Bionic type water treatment filler

A water treatment, bionic technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of decreased treatment efficiency, decreased specific surface area of fillers, small theoretical specific surface area, etc. , to achieve the effect of improving the transfer rate and utilization rate of oxygen, improving the performance of water distribution and air distribution, and improving the biological treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

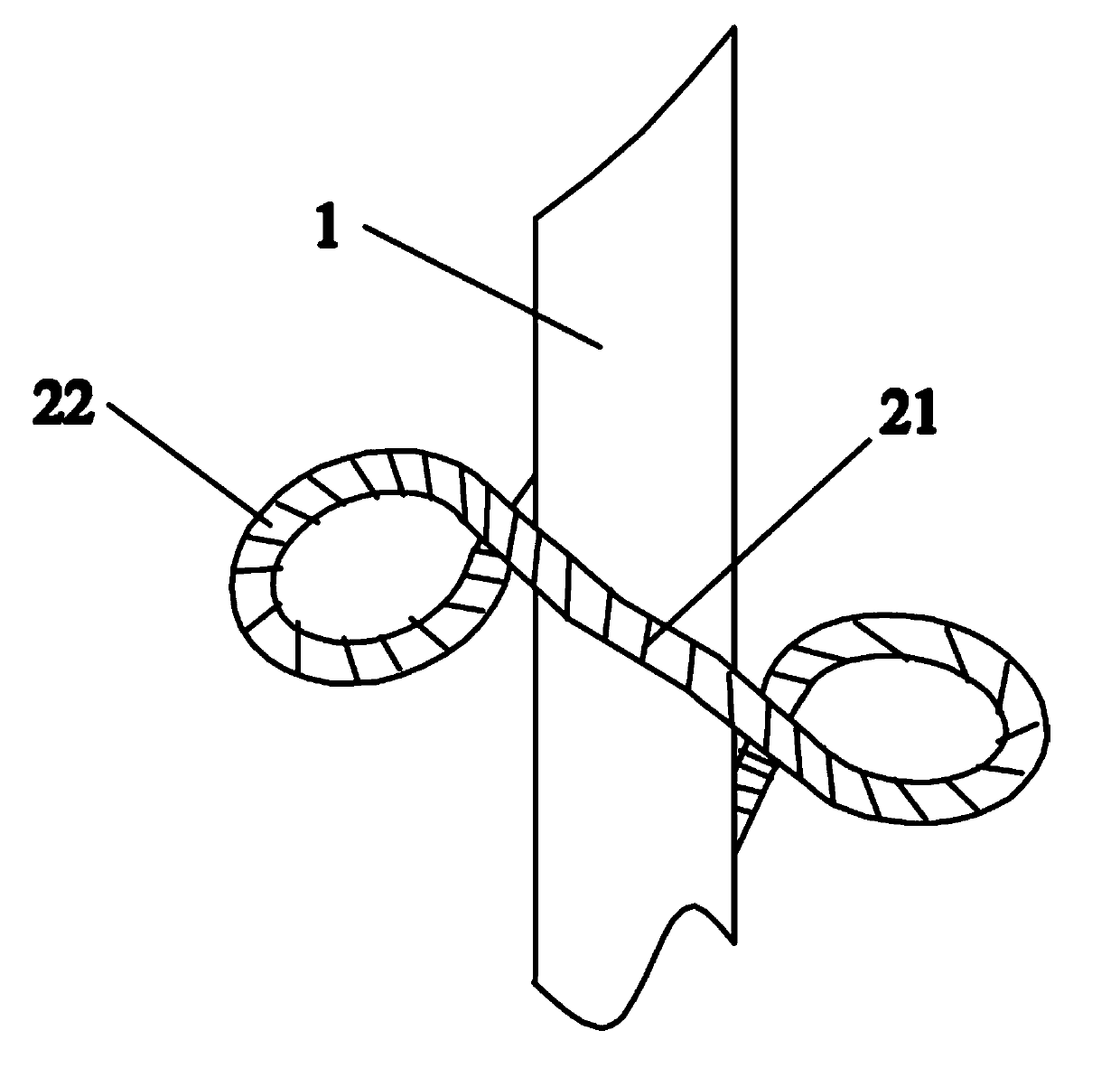

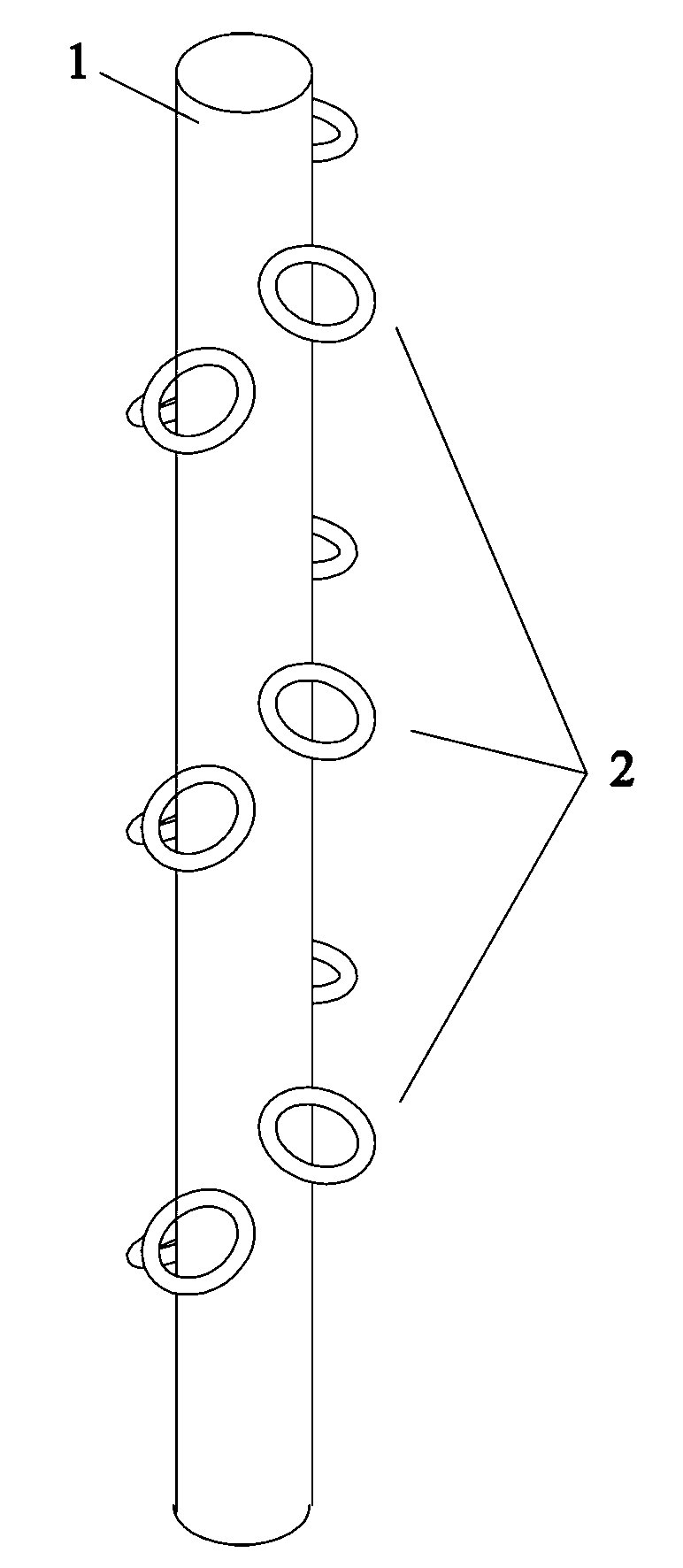

[0034] like Figure 1-2 As shown, a biomimetic water treatment filler includes an intermediate rope 1 and a filler rope wound on the intermediate rope 1. The filler rope includes several helical filler units 2 connected end to end, and each filler unit includes a threaded The first part 21 of the packing unit in the middle rope 1 and the second part 22 of the packing unit passing through the middle rope 1 , the second part 22 of the packing unit is roughly ring-shaped.

[0035] The diameter of the second part 22 of the packing unit is 20-150mm.

[0036] The filler rope comprises fiber loop wires and fiber yarns wound around the fiber loop wires.

[0037] The fiber ring filament is made of a biophilic mixture, which is made of plastic or plastic and inorganic substances after hybridization. The plastic is one of vinylon, nylon, polyester, polypropylene, polyethylene, acrylic, and polyvinyl chloride. One or more, the inorganic material is one of silicon dioxide and titanium di...

Embodiment 2

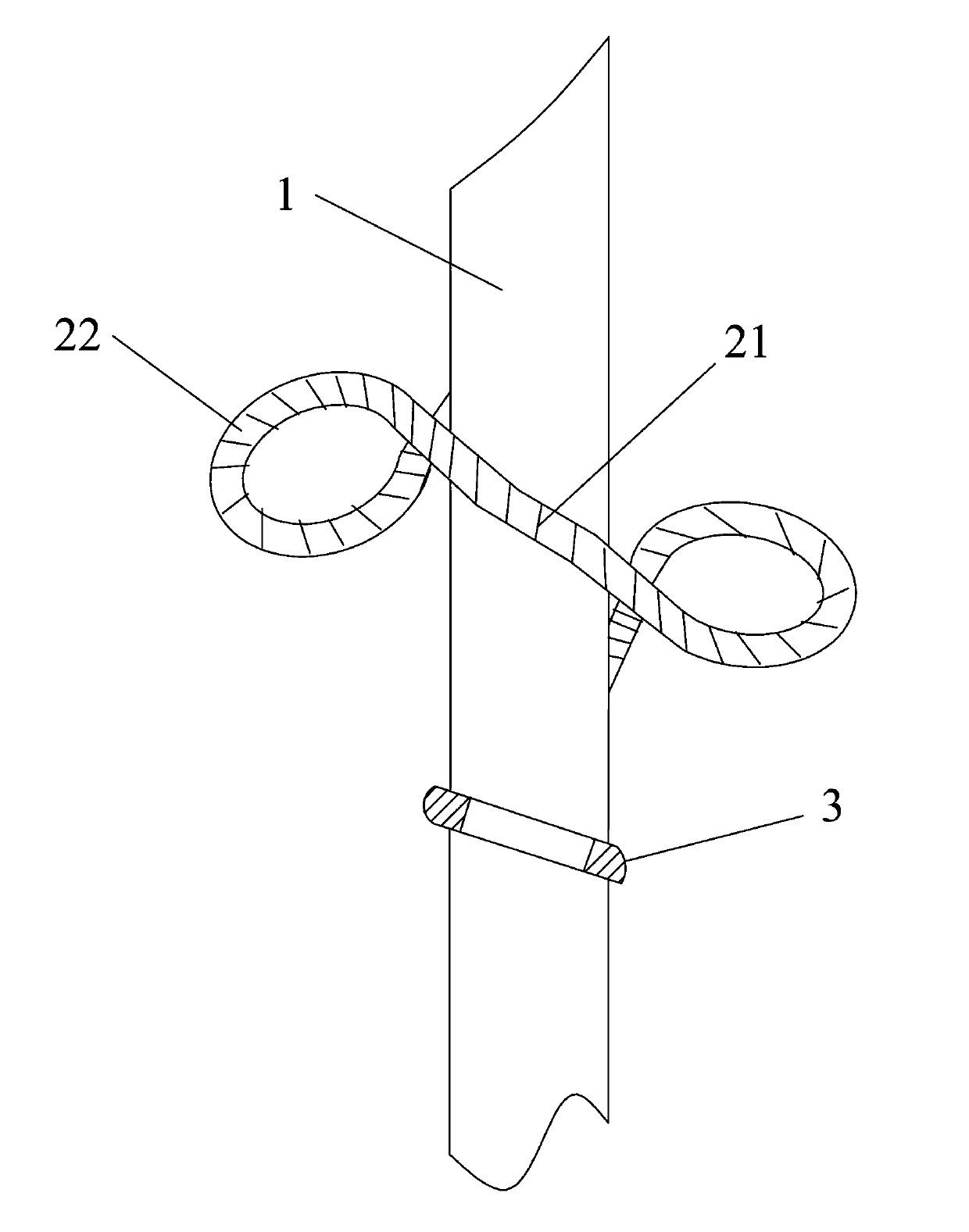

[0045] like Figure 3-5 As shown, a biomimetic water treatment filler includes an intermediate rope 1 and a filler rope wound on the intermediate rope 1. The filler rope includes several helical filler units 2 connected end to end, and each filler unit includes a threaded The first part 21 of the packing unit in the middle rope 1 and the second part 22 of the packing unit passing through the middle rope 1 , the second part 22 of the packing unit is roughly ring-shaped.

[0046] The diameter of the second part 22 of the packing unit is 20-150mm.

[0047] The filler rope comprises fiber loop wires and fiber yarns wound around the fiber loop wires.

[0048] The fiber ring filament is made of a biophilic mixture, which is made of plastic or plastic and inorganic substances after hybridization. The plastic is one of vinylon, nylon, polyester, polypropylene, polyethylene, acrylic, and polyvinyl chloride. One or more, the inorganic material is one of silicon dioxide and titanium di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com