Metal zipper polishing device and method for polishing metal zipper through utilizing same

A metal zipper and polishing device technology, which is applied in the field of metal polishing, can solve the problems of cloth belt damage, human body injury, and high production cost, and achieve the effect of low cost, simple and convenient operation, and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

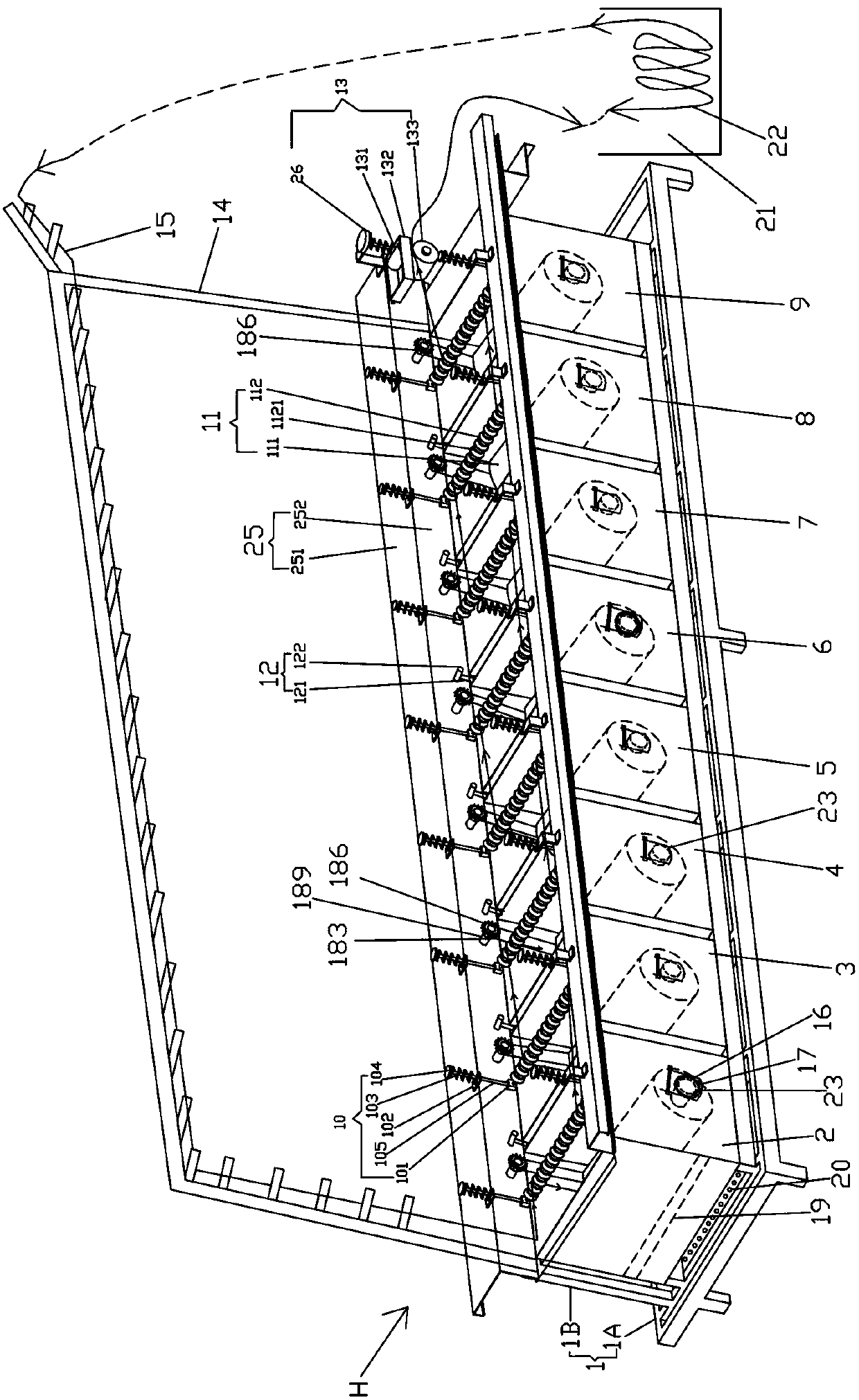

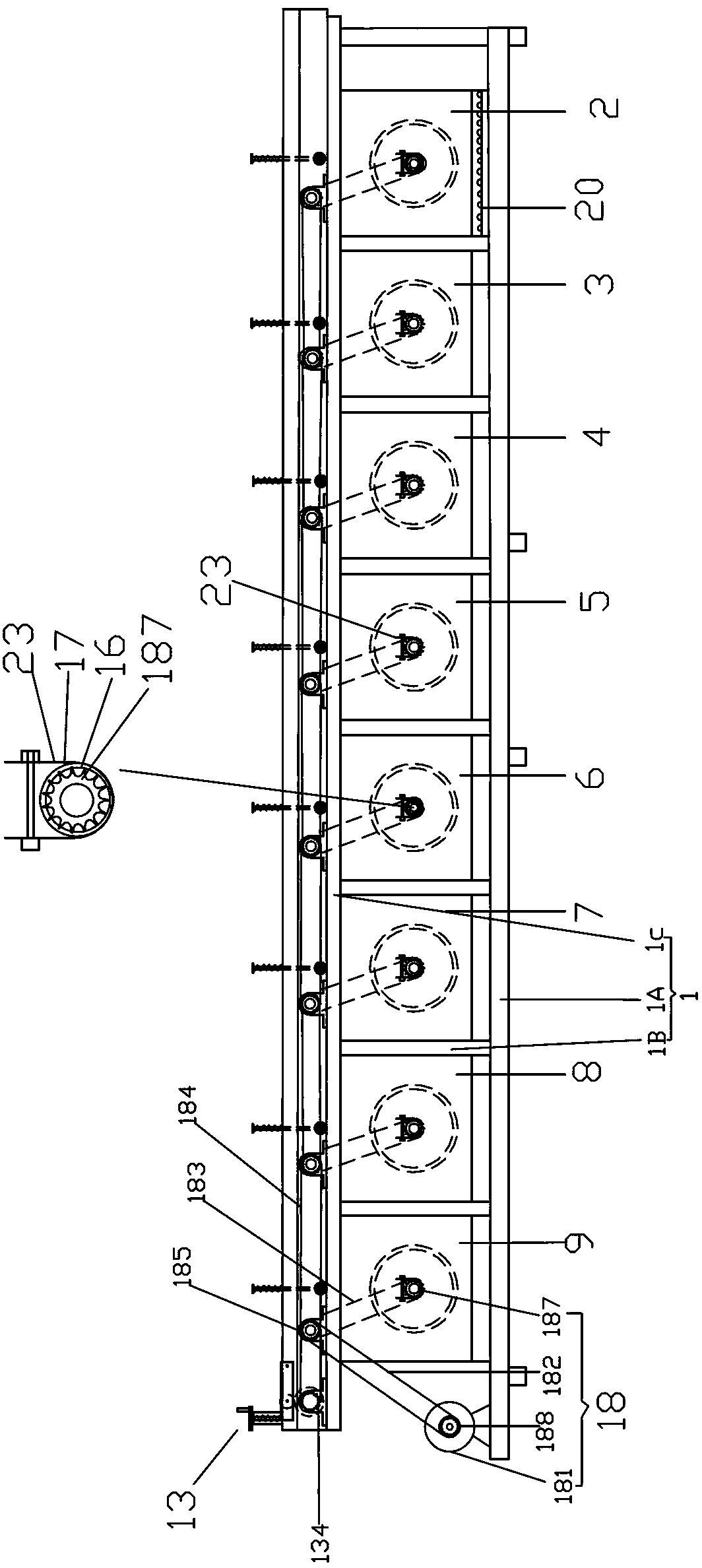

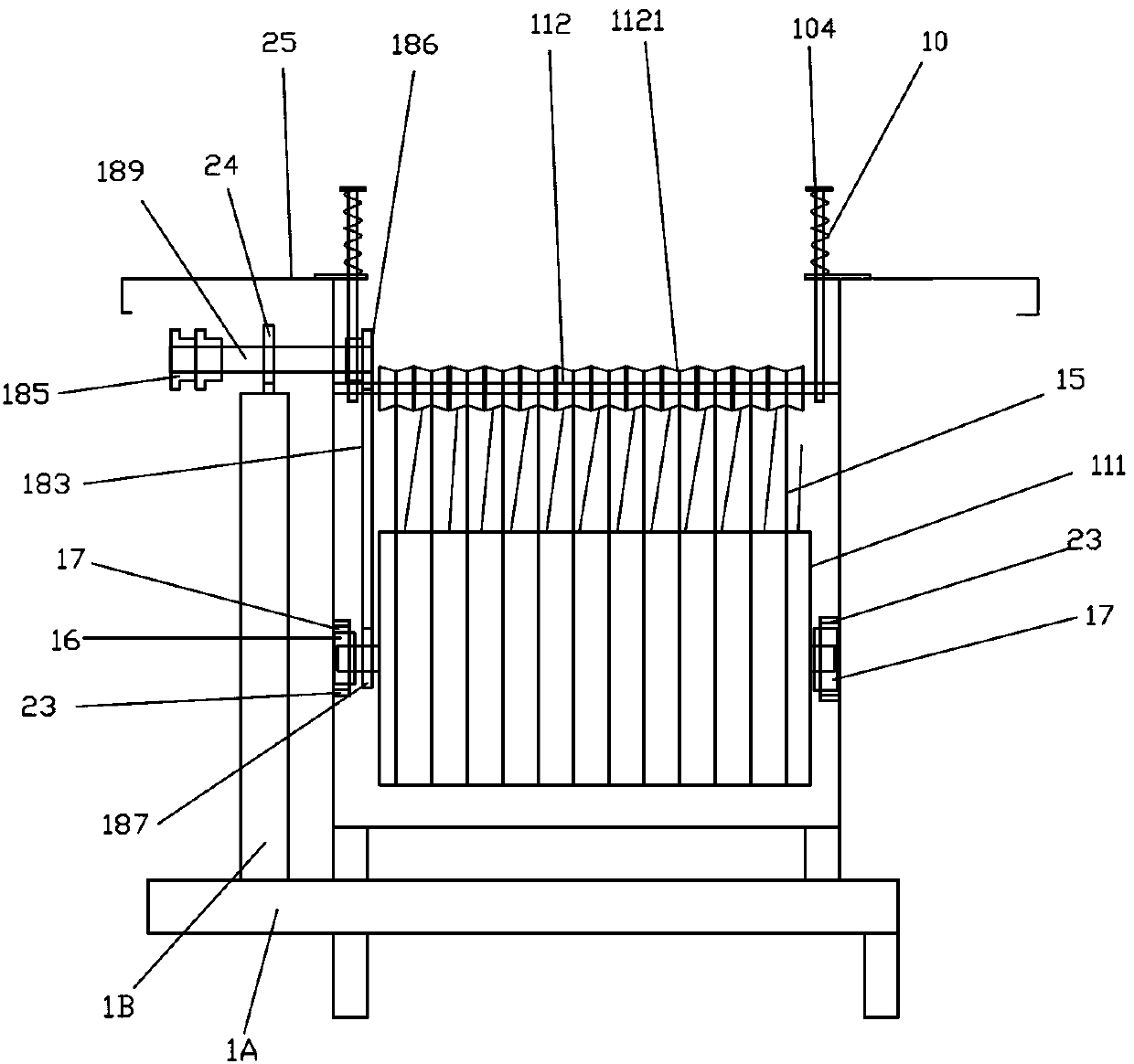

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] figure 1 , figure 2 , image 3 and Figure 4 A metal zipper polishing device according to an embodiment of the present invention is schematically shown.

[0024] As shown in the figure, the metal zipper polishing device includes a frame 1 and a tank body. The tank body is arranged on the frame 1. The frame 1 includes a chassis 1A, and is vertically fixed with a plurality of equal heights along the length direction of the chassis. Columns 1B and crossbars 1C are connected above these columns 1B. The tank body includes an electrolytic degreasing chamber 2, a first rinsing chamber 3, an acid and weak etching chamber 4, a second rinsing chamber 5, an electropolishing chamber 6, a third rinsing chamber 7, an Color-changing chamber 8, fourth rinsing chamber 9. An ultrasonic device 20 is provided at the bottom of the electrolytic degreasing chamber 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com