Washing machine

A technology of washing machine and inner tub, which is applied in the field of washing machine to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

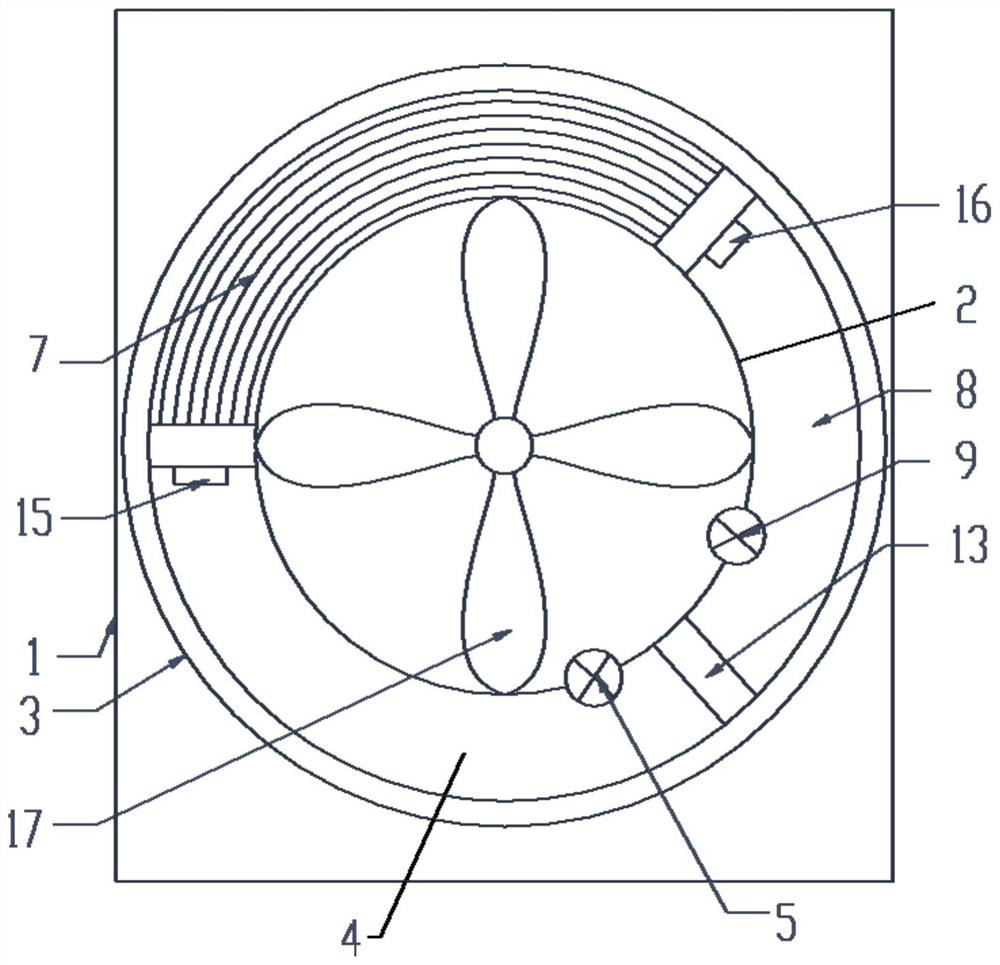

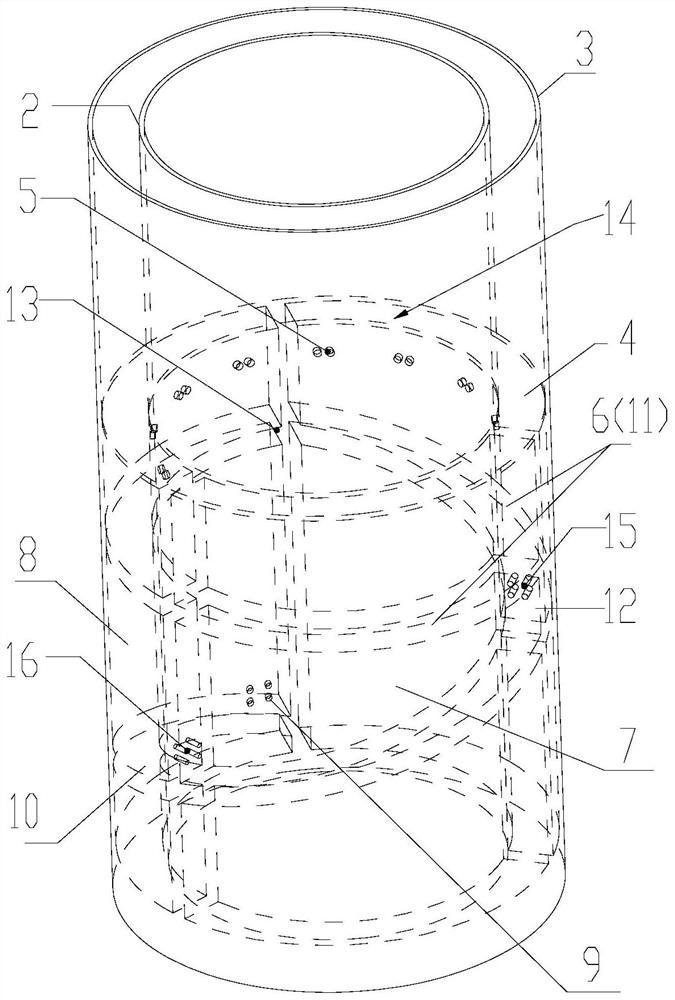

[0036] This embodiment provides a washing machine, such as figure 1 and figure 2 shown, including:

[0037] The box body 1 is provided with an accommodating chamber inside;

[0038] The first inner cylinder 2 is arranged in the accommodating cavity, and a pulsator 17 is arranged inside;

[0039]Specifically, a drive motor is installed under the pulsator 17, and the output shaft of the drive motor is connected to the pulsator 17, so that the drive of the pulsator 17 itself can be realized. During the washing process, the pulsator 17 rotates clockwise or counterclockwise, so as to drive the clothes.

[0040] The second inner cylinder 3 is sleeved on the outside of the first inner cylinder 2, and a water storage chamber is formed between the first inner cylinder 2 and the second inner cylinder 3;

[0041] Specifically, a water storage chamber is formed between the first inner cylinder 2 and the second inner cylinder 3, and the size of the water storage chamber itself is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com