Device for laying a unidirectional layer and a multi-axle knitting machine

A unidirectional and longitudinal technology, applied in warp knitting, flat warp knitting machine, knitting and other directions, can solve the problems of disturbing the quality of unidirectional yarn layers, falling, and being torn.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

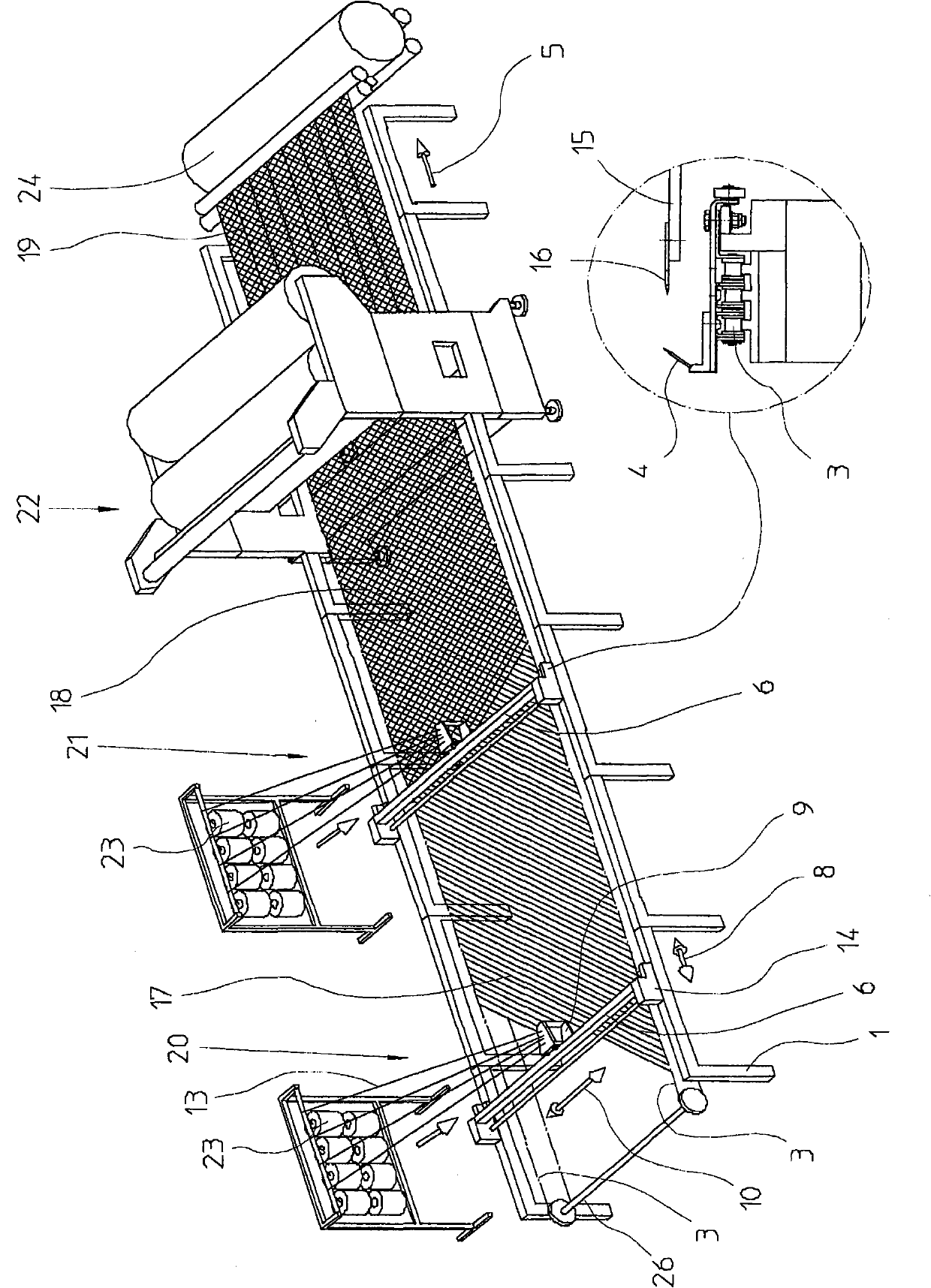

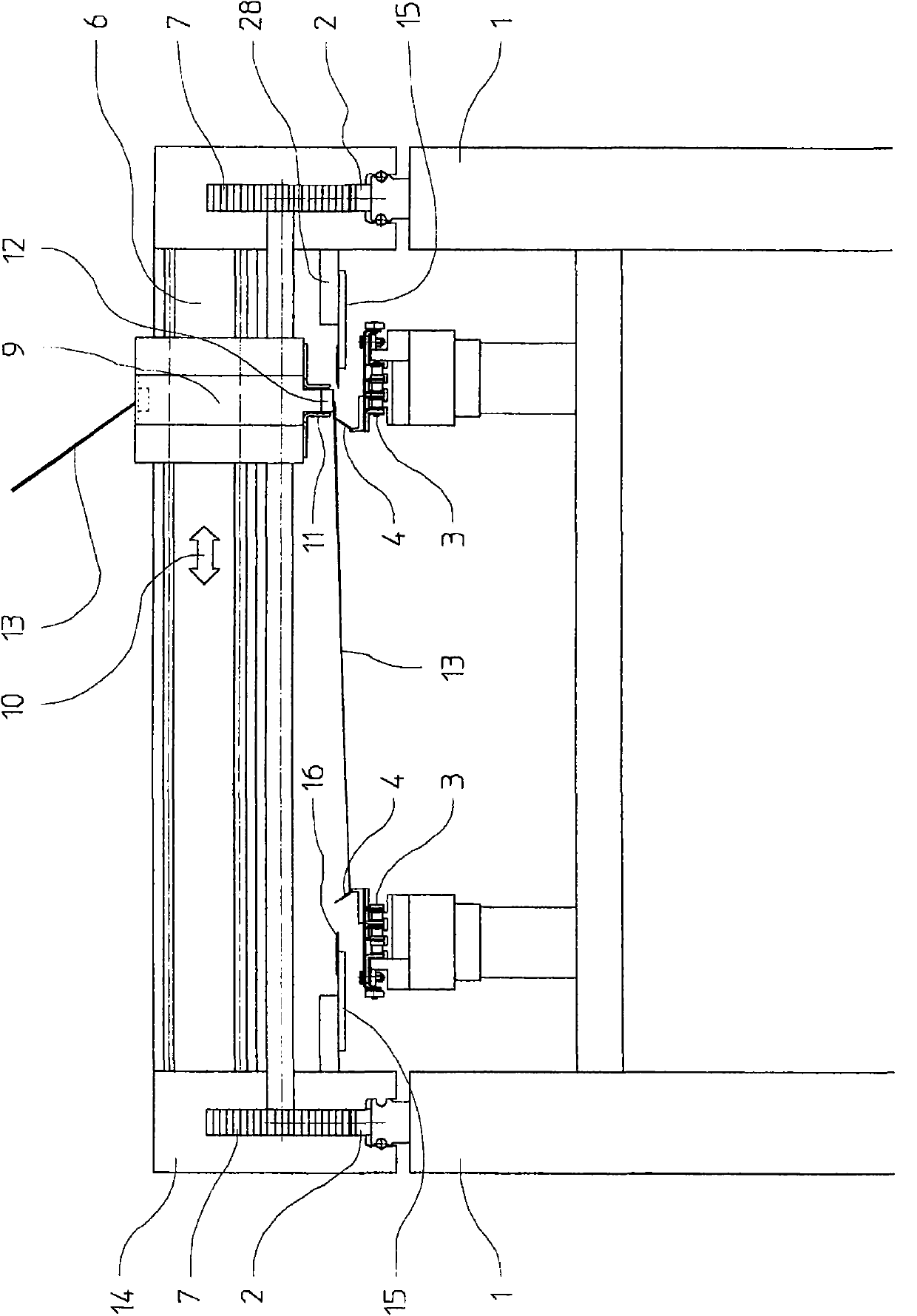

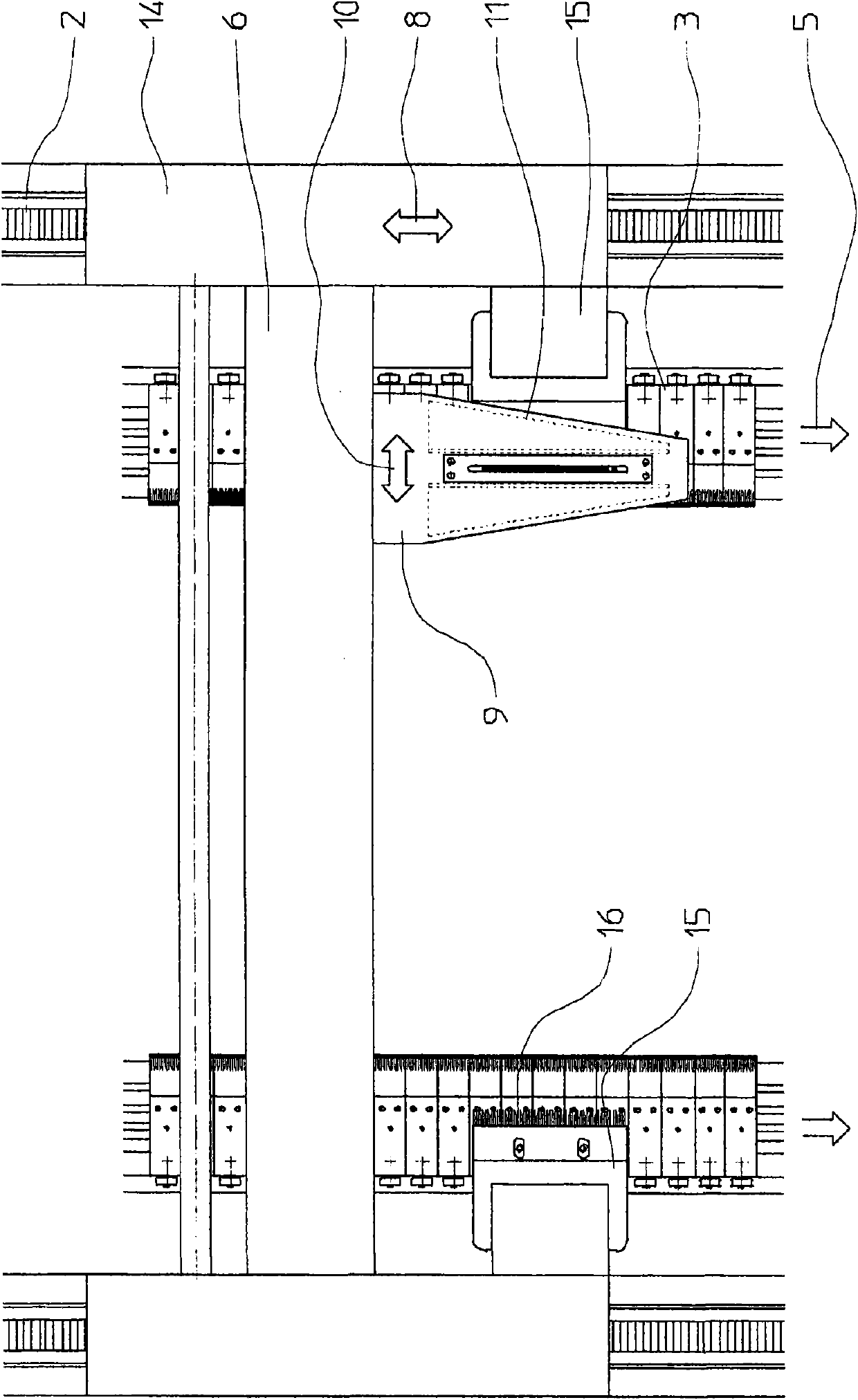

[0035] use figure 1 The multiaxial weaving machine schematically shown in produces a multiaxial yarn fabric in the form of a belt consisting of two unidirectional yarn layers. The multiaxial weaving machine has a frame consisting of two sides 1 spaced apart from one another and extends in the longitudinal direction of the tape yarn fabric to be produced. Two endless longitudinal conveyor belts 3 are arranged at a mutual transverse distance in the machine frame 1 , which are deflected on deflection axes 26 and are driven by invisible drives located in the connecting station 22 . The longitudinal conveyor belt 3 moves in the direction of travel 5 . In the example shown, the longitudinal conveyor belt 3 is designed in the form of a conveyor chain, on which there are conventional fastening hooks 4, see figure 1 Detail view shown enlarged at center lower right. In the example shown, only a single row of fastening hooks 4 is provided on each longitudinal conveyor belt 3 ; howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com