Device for braking a rail vehicle

A technology for railway locomotives and vehicles, which is applied to the parts of brakes, brake discs, and vehicle parts, etc. It can solve the problems of shortened wheel life, increased driving noise, and rough driving surface, so as to reduce wheel wear, reduce costs, and improve The effect of braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

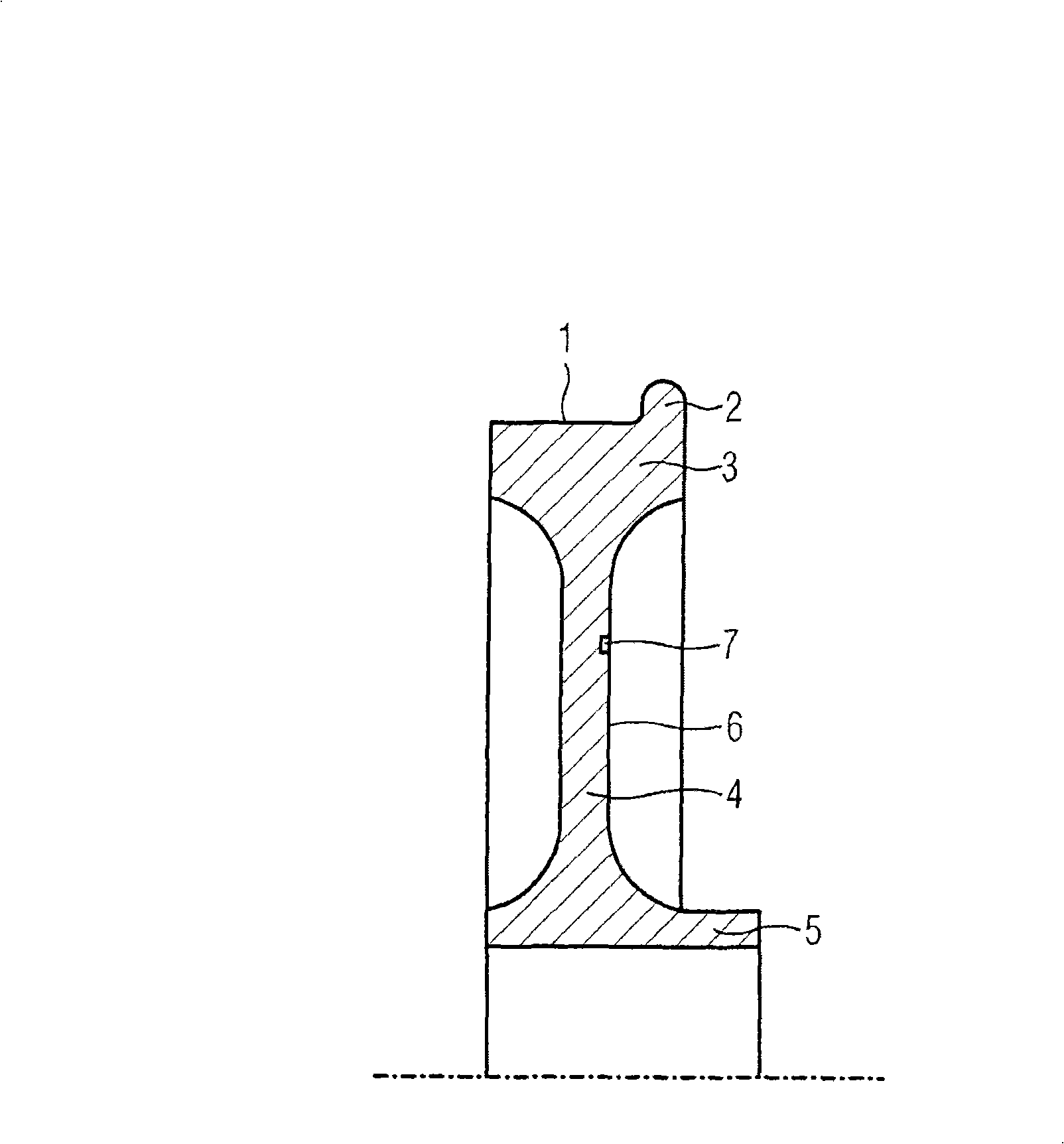

[0019] The railway wheel has a running surface 1 which is in contact with the rail, and in the region of this running surface 1 there is a flange 2 which holds the wheel on the rail. The running surface 1 and the flange 2 are components of the rim 3 . A spoke 4 is connected to the direction of the center of the wheel. The hub 5 is located in the region of the shaft. The surface area 6 acting as a friction ring is located on the spoke 4 . This surface area 6 has a special surface treatment. Grooves serving as wear markings 7 are provided on this surface region 6 .

[0020] For braking, a brake body (not shown) is pressed axially against surface region 6 .

[0021] With the brake device shown, the same effect can be achieved without wheel brake discs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com