The construction method of joint maintenance warehouse decoration and pipeline installation by using mobile scaffolding

A technology of pipeline installation and construction method, applied in industrial construction, construction material processing, housing structure support, etc., can solve problems such as delay in construction period, and achieve the effect of speeding up construction progress, flexible erection type, and easy and fast erection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the construction method for decoration of combined maintenance warehouse and installation of pipelines provided by the present invention using mobile scaffolding will be described in detail in conjunction with the accompanying drawings and specific embodiments.

[0027] like figure 1 — Figure 18 As shown, the construction method of utilizing mobile scaffolding to carry out joint maintenance warehouse decoration and pipeline installation provided by the present invention includes the following steps carried out in order:

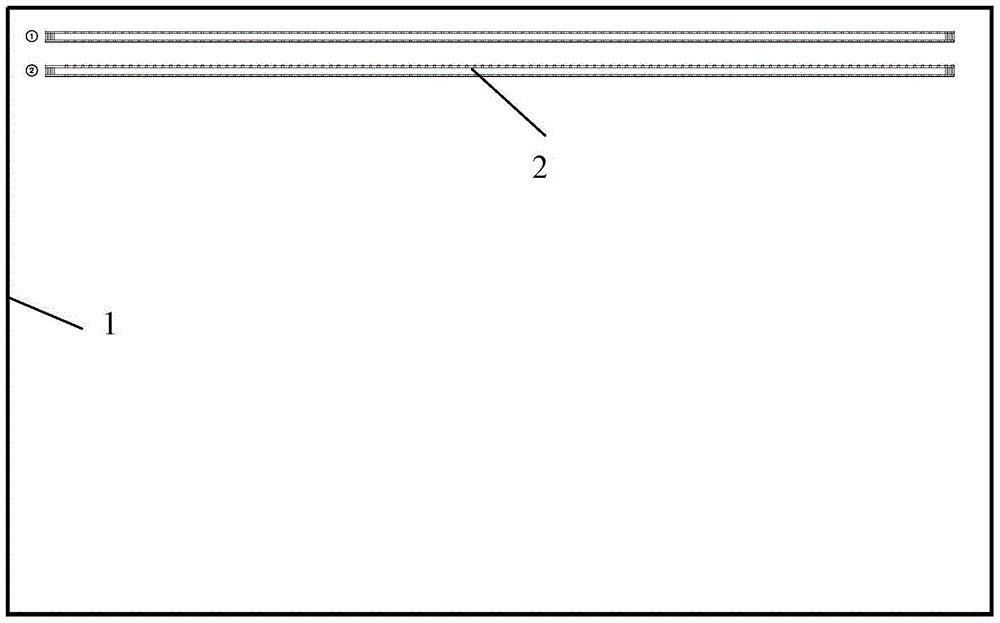

[0028] 1) First, carry out the construction of the first and second inspection pits 2 in the completed warehouse 1, and then carry out the construction of the remaining inspection pits 2 successively;

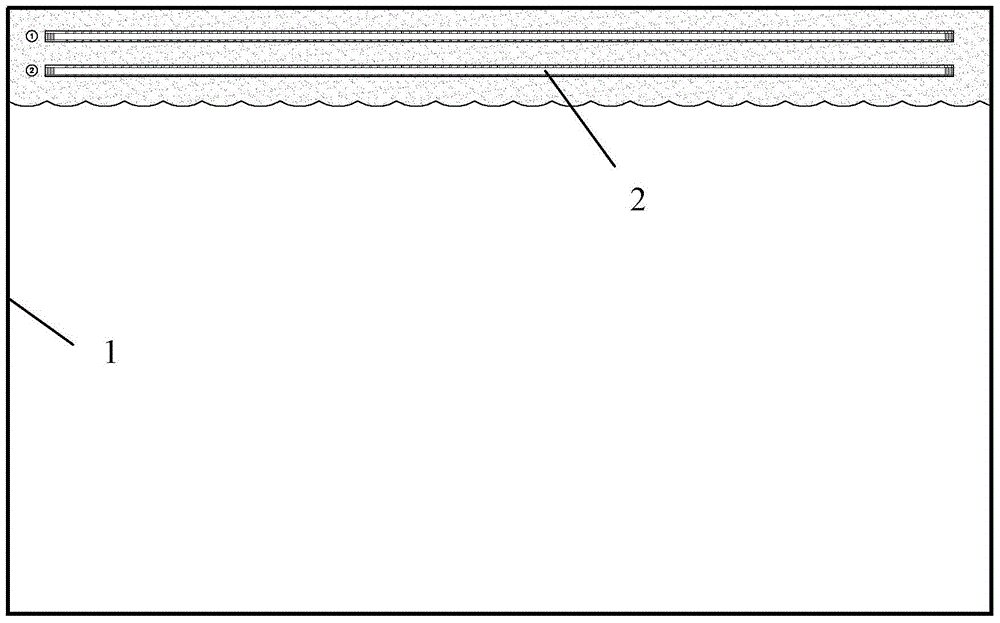

[0029] 2) Carry out indoor filling around the first and second inspection pits 2 that have been built;

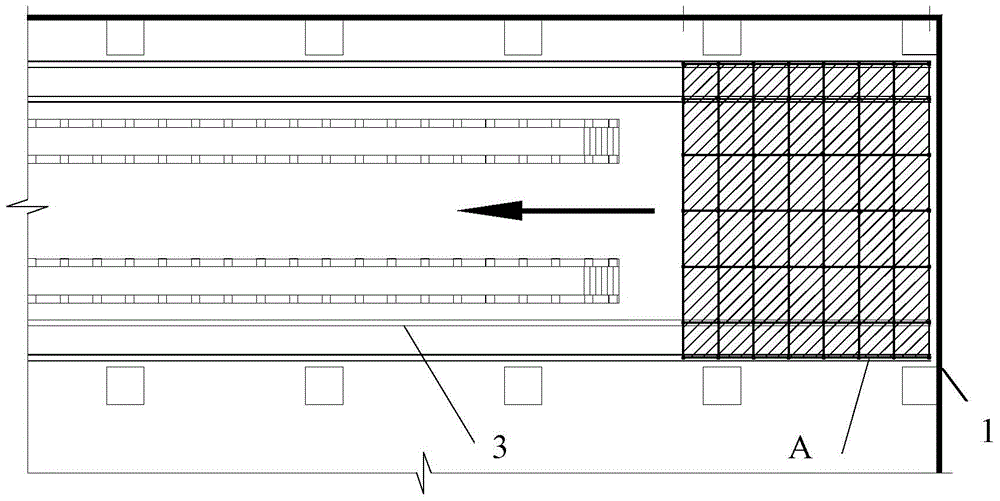

[0030] 3) Lay a guide rail 3 on the backfill soil on both sides of the first and second inspection pits 2, and set up a roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com