Method for jointly decorating maintenance storehouses and installing and constructing pipelines by aid of movable scaffolds

A pipeline installation and construction method technology, which is applied in industrial buildings, building structure support, building structure support, etc., can solve problems such as delays in the construction period, and achieve the effects of speeding up the construction progress, flexible erection types, and easy and fast erection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following describes in detail the construction method for joint maintenance warehouse decoration and pipeline installation provided by the present invention by using mobile scaffolding with reference to the accompanying drawings and specific embodiments.

[0027] Such as figure 1 — Figure 18 As shown, the method of using mobile scaffolding for joint maintenance warehouse decoration and pipeline installation provided by the present invention includes the following steps in sequence:

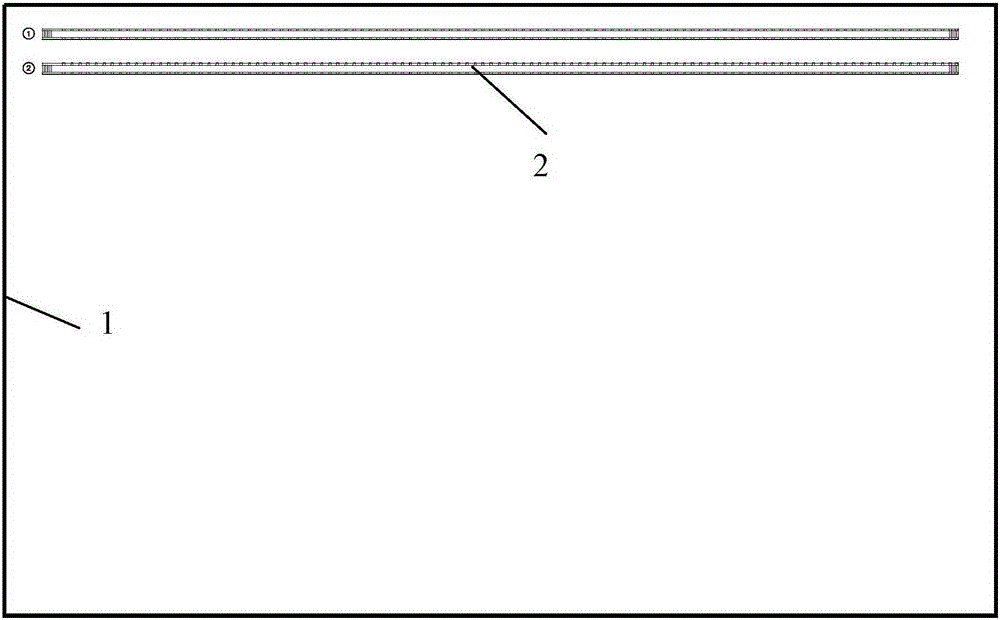

[0028] 1) First, carry out the construction of the first and second inspection pits 2 in the built warehouse 1, and then continue the construction of the remaining inspection pits 2;

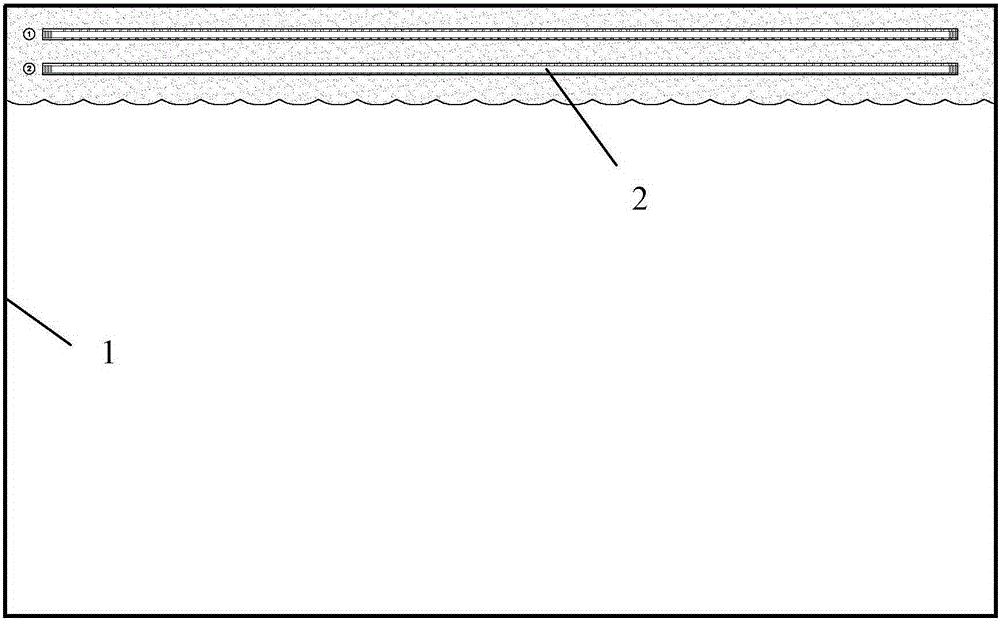

[0029] 2) Fill indoors around the first and second inspection pits 2 that have been built;

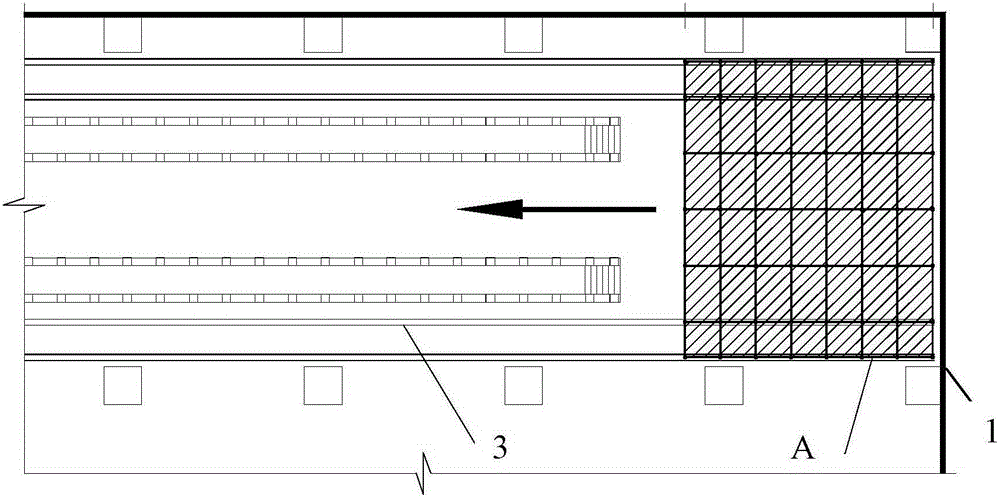

[0030] 3) Lay a guide track 3 on the backfill on both sides of the first and second inspection pits 2, and set up a guide track 3 on the outer side of one end of the first and second inspection pits 2 with a roller at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com