Reinforcing steel bar sleeve grouting device

A steel sleeve and slurry technology, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of increased construction procedures, cumbersome operations, and increased construction costs, and achieve simplified construction procedures, improved connection strength, and reduced The effect of engineering expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

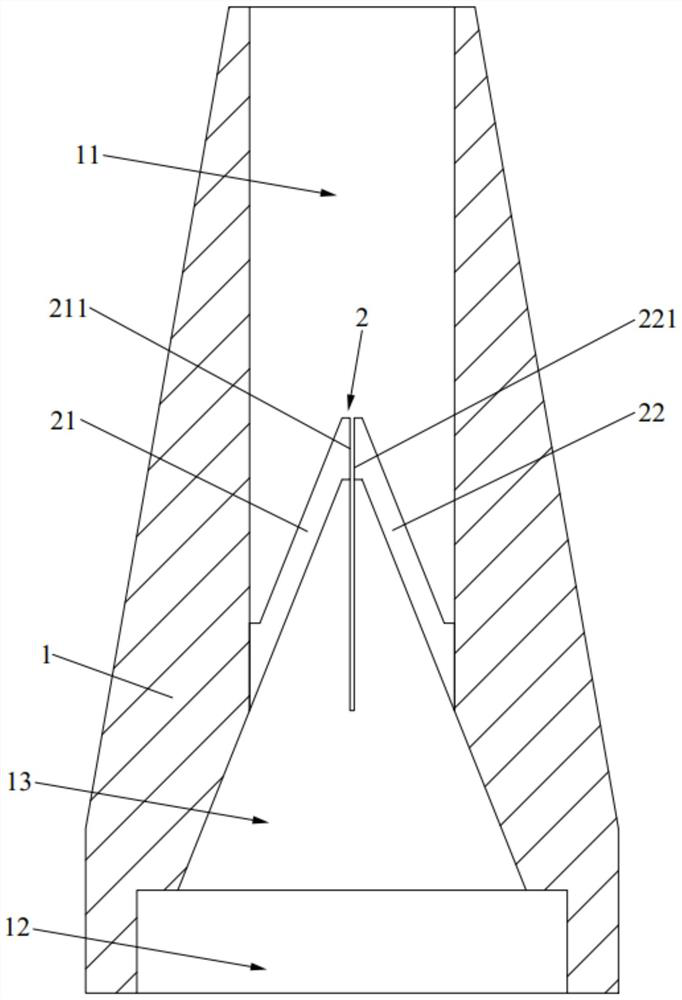

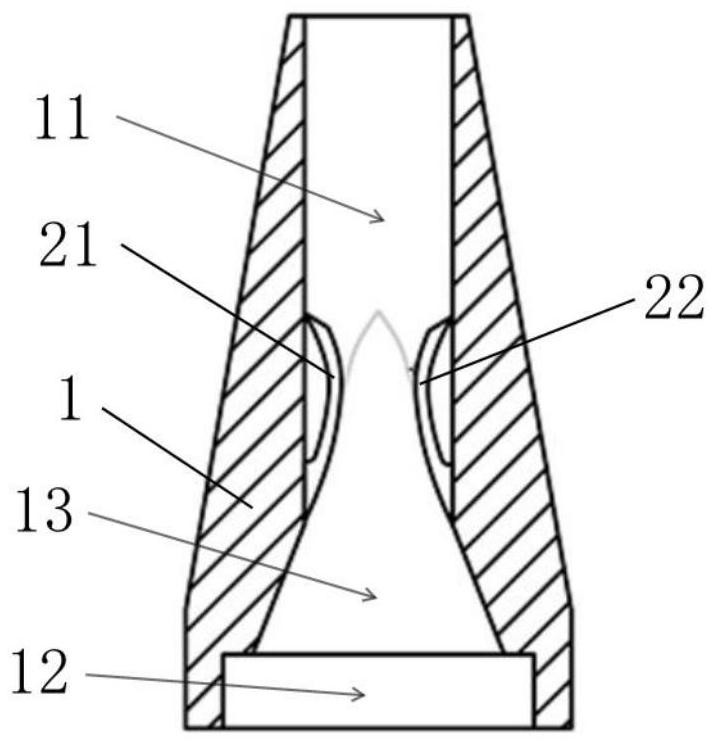

[0038] Such as figure 1 and figure 2 As shown, the present embodiment provides a kind of reinforcing bar sleeve grouting device, comprises grouting pipe plug 1, and one end of grouting pipe plug 1 communicates with the grouting end of grouting equipment, and the other end communicates with reinforcing bar sleeve, that is, injecting The grouting equipment pours concrete grout into the steel bar sleeve through the grouting pipe plug 1, thereby connecting two sections of steel bars.

[0039] The inner wall of the grouting pipe plug 1 is provided with a non-return structure 2. When the grouting equipment grouts into the steel sleeve, the non-return structure 2 is in an open state, so that the concrete slurry in the grouting equipment can pass through the grouting pipe plug smoothly. 1, and enter the reinforcement sleeve; when the reinforcement sleeve is filled with concrete slurry, remove the grouting end of the grouting equipment from the grouting pipe plug 1, at this time, the...

Embodiment 2

[0058] Such as image 3 As shown, this embodiment provides a steel sleeve grouting device, wherein the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment. For the sake of brevity, only the difference between Embodiment 2 and Embodiment 1 will be described. The difference is that in this embodiment, the opening of the first valve 21 and the second valve 22 is not realized by the pressure of the concrete slurry, but The pressing force is applied through the grouting equipment, so that the first valve 21 and the second valve 22 are elastically deformed, so as to switch to the open state. Since the concrete slurry is directly pressed against the non-return structure 2 to realize opening, the grouting pressure needs to be increased to a certain extent to ensure that the concrete slurry can press open the first valve 21 and the second valve 22 . In this embodiment, the first valve ...

Embodiment 3

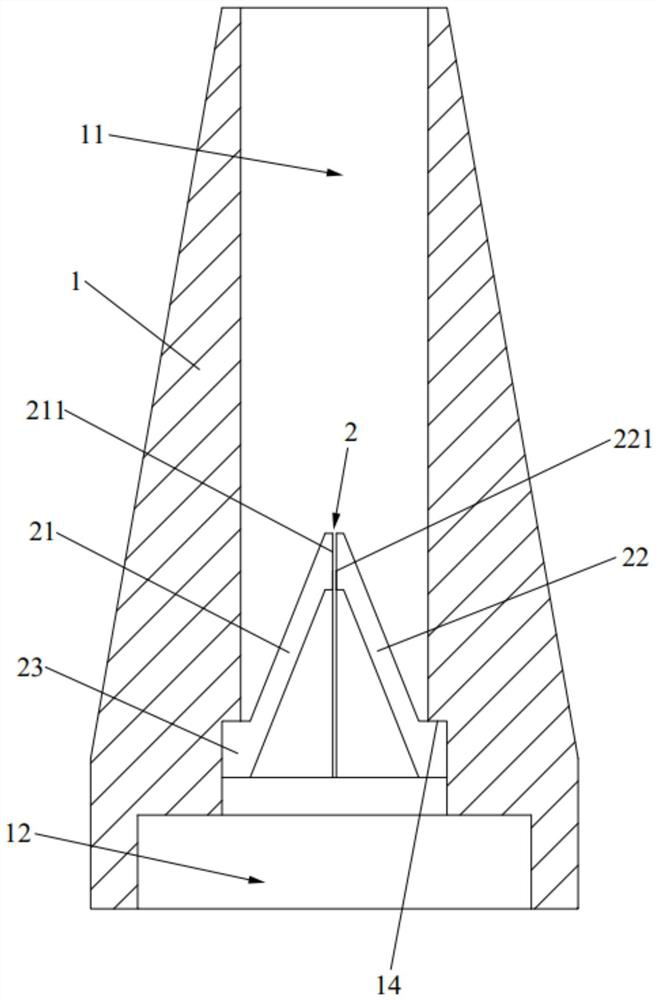

[0064] Such as Figure 4 and Figure 5As shown, this embodiment provides a steel sleeve grouting device, wherein the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to those in the first embodiment. For the sake of brevity, only the difference between Embodiment 3 and Embodiment 1 will be described. The difference is that in this embodiment, the opening of the first valve 21 and the second valve 22 is directly abutting against the first valve through the grouting equipment. 21 and the second valve 22, so that both are elastically deformed, thereby switching to the open state.

[0065] Optionally, in this embodiment, the non-return structure 2 is integrally formed with the grouting pipe plug 1 . see Figure 4 , the end of the first valve 21 and the second valve 22 away from the steel pipe sleeve is the contraction clamping end 212 . When grouting, the grouting end of the grouting equipment is directly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com