A multi-stage feeding pneumatic conveying device

A pneumatic conveying and feeding technology, which is applied in the field of pneumatic conveying devices and multi-stage feeding pneumatic conveying devices, can solve the problems of low feeding height, wide feeding range, and large feeding volume, so as to avoid blocking the discharge port , avoid material backflow, and meet the effect of large feeding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

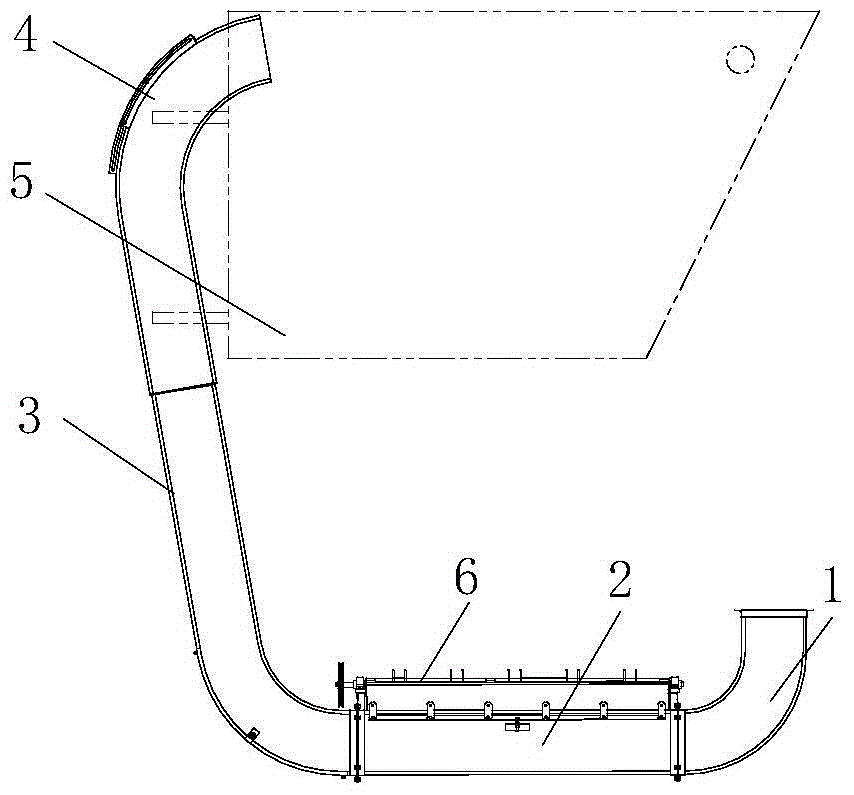

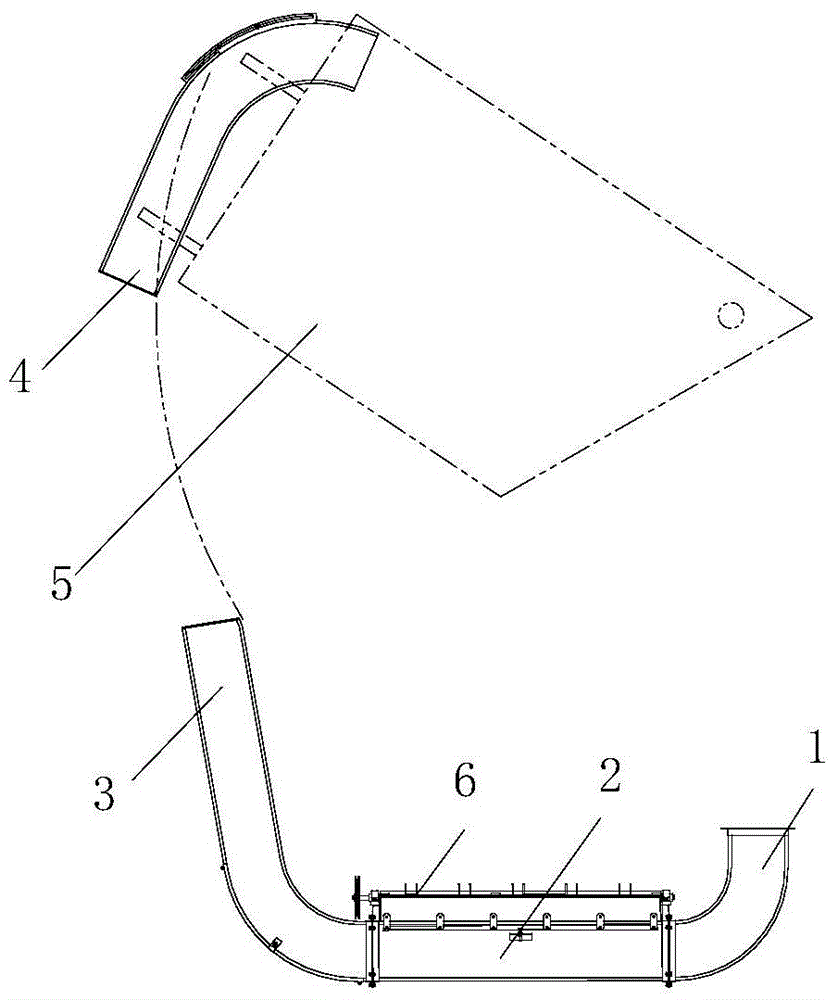

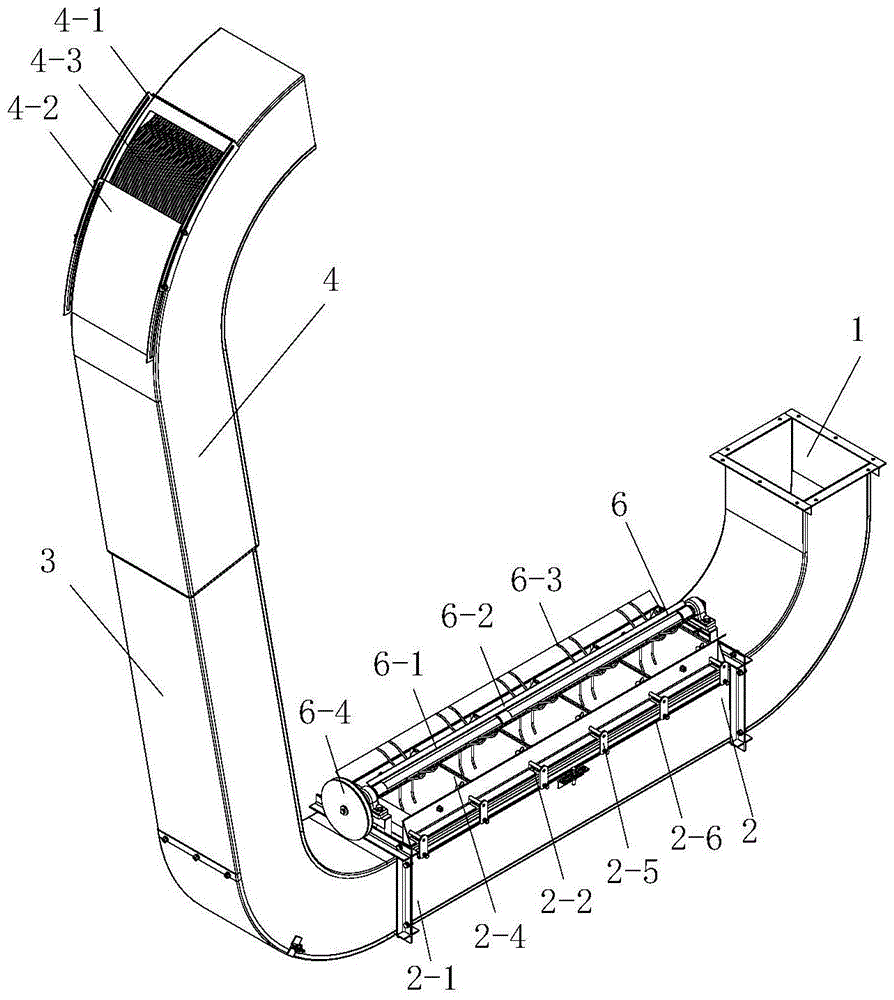

[0026] The basic structure of the multi-stage feeding pneumatic conveying device in this embodiment is as follows: figure 1 As shown, it includes a 90° elbow air inlet pipe 1 connected between the air inlet end and the air outlet of the fan. The upper end of 3 is plugged and communicated with the material throwing pipe 4 . The outlet of the throwing pipe 4 is fixedly connected with the fruit box 5 tops hinged on the loading vehicle, and its lower end is inserted on the feeding pipe 3, so as figure 2 As shown, it can be unloaded together with the fruit box.

[0027] Feeder 2 such as image 3 , 4 As shown in , 5, the main body is a pipe groove 2-1 with a feeding port on the top, and the opening of the pipe groove 2-1 blanking port supports five rotating shafts 2-2 perpendicular to the material conveying direction at intervals, and the rotating shaft 2- 2. Fix the guide block 2-3 whose section is a right-angled trapezoid. The specific structure of diversion block 2-3 is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com