Glue-sizing double R groove shaped conductive thread expanding pulley

A pay-off pulley and groove-shaped technology, which is applied in the field of overhead power transmission line tension stringing construction equipment, can solve the problem of reducing the contact area between the wire and the wire pay-off pulley groove, wire wear and tear, wire pay-off pulley structure deformation, and reduction of discharge. The service life of wire pulleys and other issues can be improved to improve safety and wire efficiency, save engineering expenses, and reduce corona loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

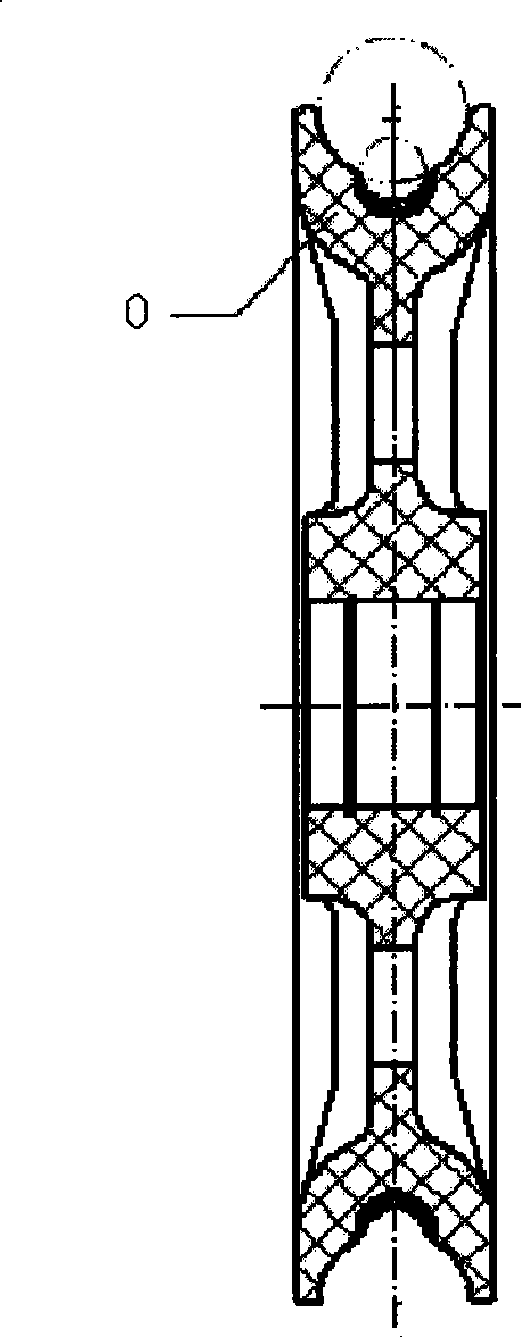

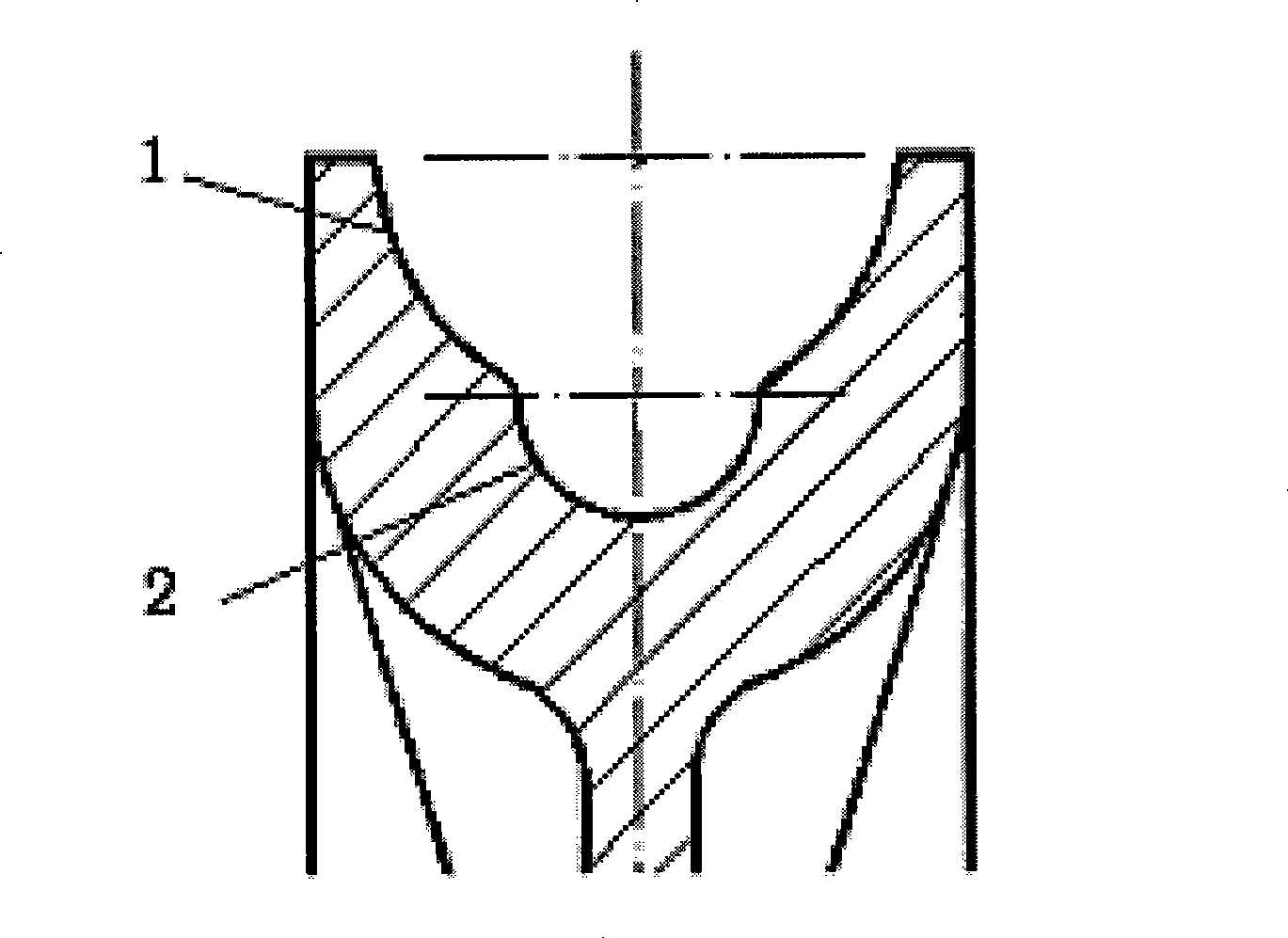

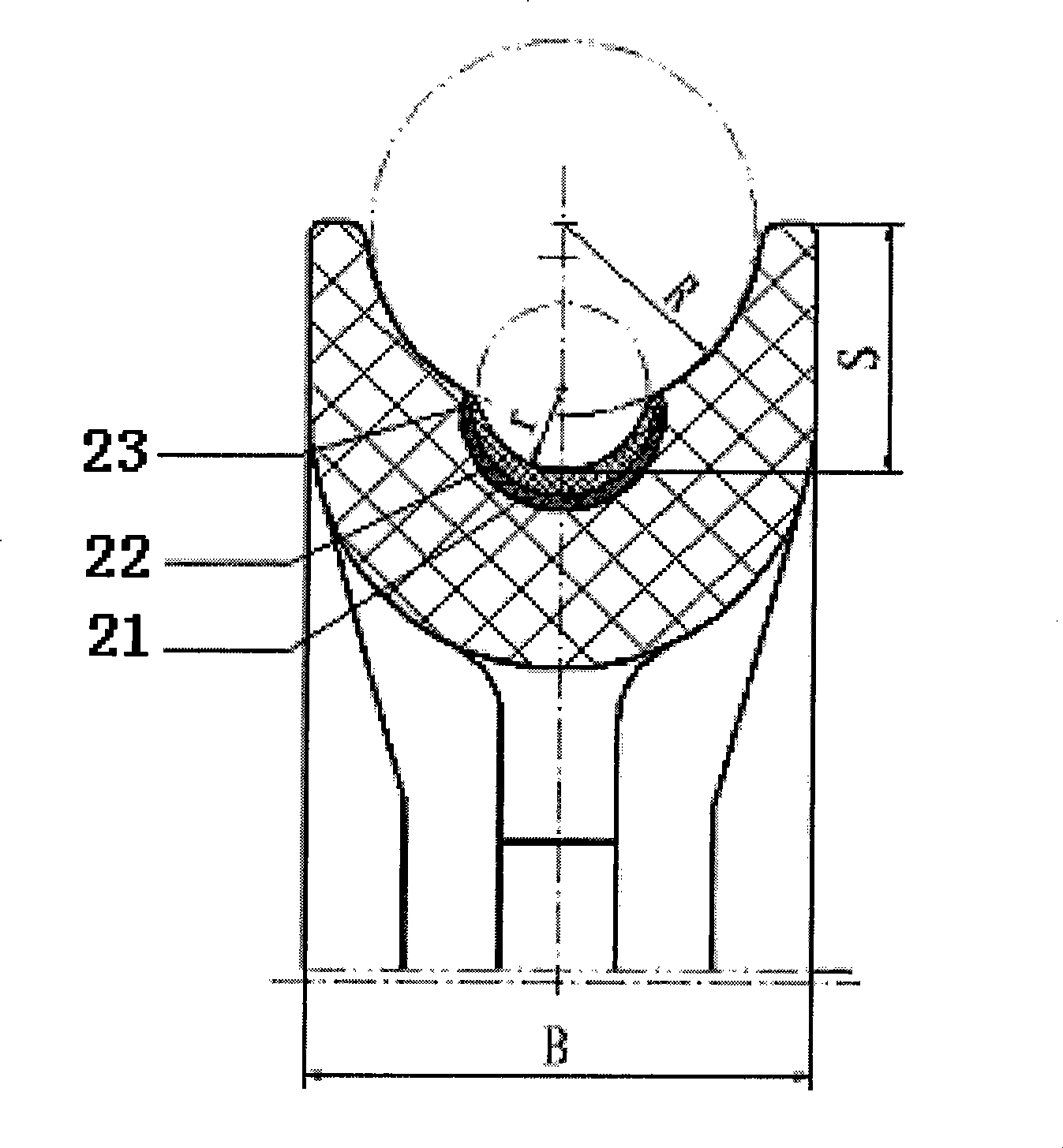

[0023] figure 1 Shown is the general structure schematic diagram of the double R groove shape wire pay-off pulley of the present invention, the wheel groove of the pulley body of the wire pay-off pulley on it adopts the double R groove shape of hanging glue, promptly is made up of two circular arc grooves 1, 1 and 2. 2, a smaller radius arc groove 2 is set at the bottom of the larger radius arc groove 1; also for the purpose of protecting the wire, the connection between the large and small arcs 1 and 2 has a chamfer. A glue-hanging layer 22 is provided on at least the inner surface of the arc groove with a smaller radius. The thickness of the pay-off pulley is B, and the total depth of the wheel groove is S. The large and small arc radii R and r after gluing are matched with the radii of the splicing tube protection device and the wire respectively, image 3 It is a schematic diagram of the first glue-hanging method of the wire pay-off pulley, Figure 4 It is a schematic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com