Diamond wire cutting material receiving device

A diamond wire cutting and splicing device technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., to achieve the effect of improving cutting efficiency, high degree of mechanization, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

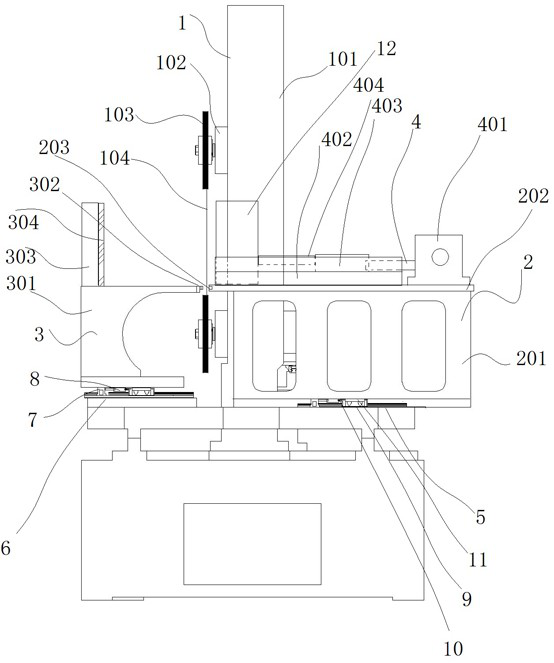

[0018] Embodiment 1: A diamond wire cutting material receiving device, including a cutting mechanism 1, a cutting table assembly 2 and a material receiving table assembly 3, the material receiving table assembly 3 is arranged at one end of the cutting table assembly 2, and the cutting table assembly 2 There is a gap between the material receiving table assembly 3, and the cutting part of the cutting mechanism 1 is set in the gap; the cutting table assembly 2 is provided with a pushing mechanism 4, and the bottom end of the cutting table assembly 2 is arranged in the X direction On the sliding mechanism 5, the X-direction sliding mechanism 5 drives the cutting table assembly 2 to move back and forth in the X direction. Move left and right in the Y direction to dock with the cutting table assembly 2, the middle part of the side end of the material receiving table assembly 3 is provided with a positioning protrusion, the side end of the cutting table assembly 2 is provided with a ...

Embodiment 2

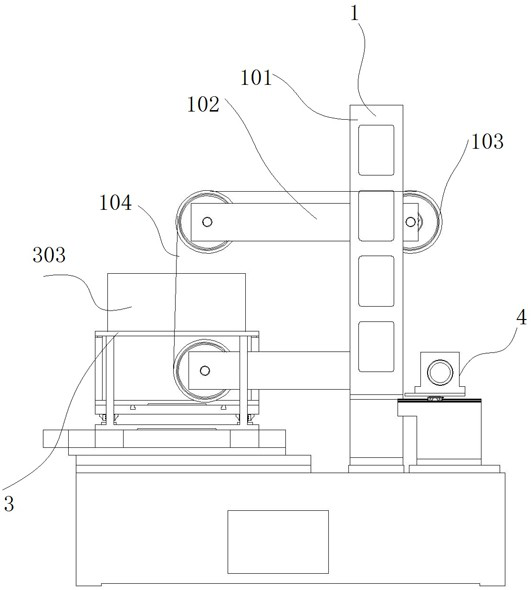

[0019] Embodiment 2: The cutting mechanism 1 includes a support column 101, a support roller plate 102, a wire roller 103 and a diamond wire 104, and the upper and lower ends of the support column 101 are fixedly equipped with a support roller plate 102, and the support roller plate 102 Both ends are equipped with wire rollers 103 and are hinged with them. The diamond wires 104 are wound on the wire rollers 103 in turn, and the rest of the technical solutions are the same as those in the first embodiment.

Embodiment 3

[0020] Embodiment 3: The cutting table assembly 2 includes a platform support frame 201, a cutting table 202, a relief groove 203 and a chute, the platform support frame 201 is fixedly equipped with a cutting table 202, and the side of the cutting table 202 is A relief groove 203 is provided at the end, and a chute is provided at the top of the cutting table 202, and the rest of the technical solutions are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com