Cable snakelike bending machine

A technology of bending machine and cable snake, which is applied in the field of cable snake bending machine, can solve the problems of inconvenient construction, scratched cable skin, and low construction efficiency, so as to reduce engineering expenses, improve work efficiency, ensure accuracy and maintain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

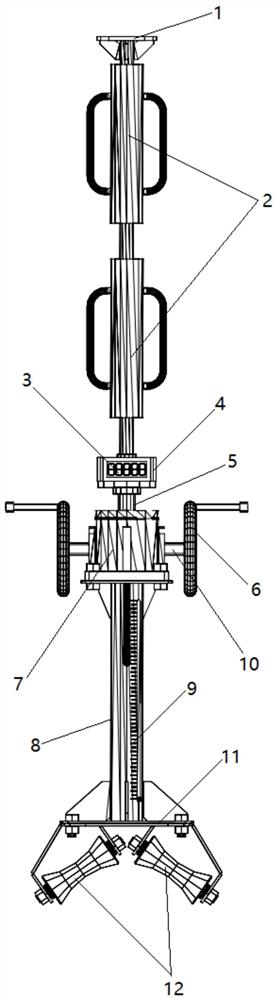

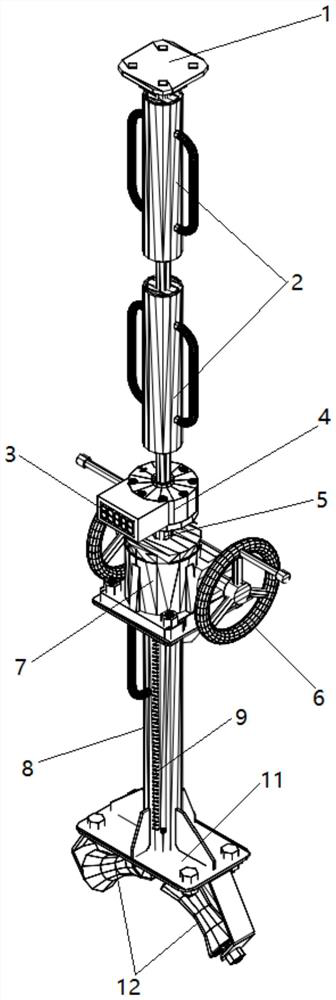

[0034] Such as figure 1 and figure 2 As shown, a cable serpentine bending machine includes top support 1, force supporting tooling, pressure sensor 4, jacking mechanism, rack mechanism 8, and bending rollers connected sequentially from the beginning to the end; the top support and the outside world Contact, such as: the top brace is in contact with the tunnel roof; the top brace consists of a square bottom plate with four bolt holes, four triangular webs, and the middle main shaft is a steel pipe with external threads. The top support 1, the force supporting tooling, the pressure sensor 4, the jacking mechanism, the frame mechanism 8, and the bending rollers are all detachably connected. The jacking mechanism includes a screw mandrel 5, a turbine mechanism 7, a hand wheel 6, and a rocker input shaft 10; the inside of the turbine mechanism 7 is vertically provided with a screw rod 5, and the inside of the turbine mechanism 7 is horizontally provided with a rocker input shaft....

Embodiment 2

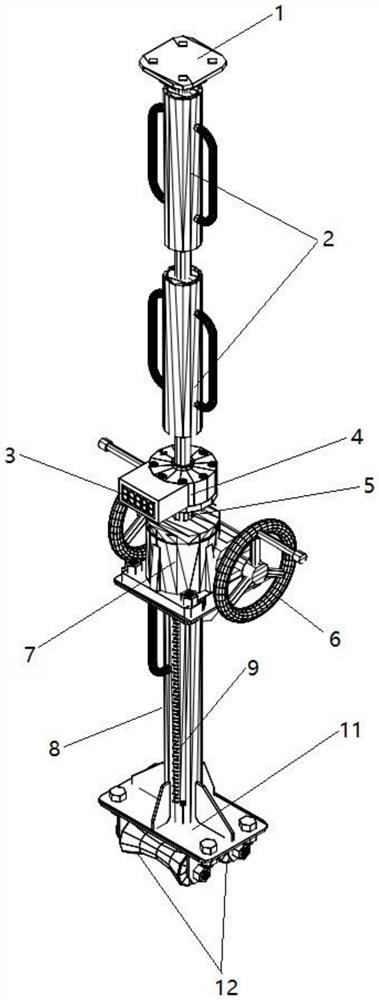

[0039] Such as image 3 As shown, a cable serpentine bending machine includes top support 1, force supporting tooling, pressure sensor 4, jacking mechanism, rack mechanism 8, and bending rollers connected sequentially from the beginning to the end; the top support and the outside world Contact, such as: the top brace is in contact with the tunnel roof; the top brace consists of a square bottom plate with four bolt holes, four triangular webs, and the middle main shaft is a steel pipe with external threads. The top support 1, the force supporting tooling, the pressure sensor 4, the jacking mechanism, the frame mechanism 8, and the bending rollers are all detachably connected. The jacking mechanism includes a screw mandrel 5, a turbine mechanism 7, a hand wheel 6, and a rocker input shaft 10; the inside of the turbine mechanism 7 is vertically provided with a screw rod 5, and the inside of the turbine mechanism 7 is horizontally provided with a rocker input shaft. Shaft 10, scr...

Embodiment 3

[0044] A cable serpentine bending machine, including a top support 1, a force supporting tool, a pressure sensor 4, a jacking mechanism, a frame mechanism 8, and bending rollers connected sequentially from the beginning to the end; the top support is in contact with the outside world, such as : The top brace is in contact with the tunnel roof; the top brace consists of a square bottom plate with four bolt holes, four triangular webs, and the middle main shaft is a steel pipe with external threads. The top support 1, the force supporting tooling, the pressure sensor 4, the jacking mechanism, the frame mechanism 8, and the bending rollers are all detachably connected. The jacking mechanism includes a screw mandrel 5, a turbine mechanism 7, a hand wheel 6, and a rocker input shaft 10; the inside of the turbine mechanism 7 is vertically provided with a screw rod 5, and the inside of the turbine mechanism 7 is horizontally provided with a rocker input shaft. Shaft 10, screw mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com