A bending device for serpentine laying of large cross-section power cables

A cable snake and large-section technology, applied in the field of power cable benders, can solve the problems of inadequate control of the snake-shaped wave amplitude, difficulty in forming a snake-shaped bend, and difficulty in cable laying, etc., so as to reduce the investment of construction personnel and ensure the cable The effect of laying and reducing engineering expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

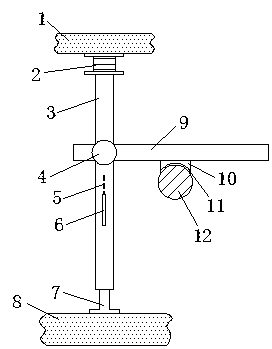

[0026] Such as figure 1 As shown, the amplitude marking device is a scale 6, and the support rod 3 is provided with a suspension gap 5 for hanging the scale 6. There can be multiple suspension gaps 5, which is convenient for adjusting the position of the scale 6 and adapting to the bending of cables 12 of different heights or amplitudes. Laying.

Embodiment 2

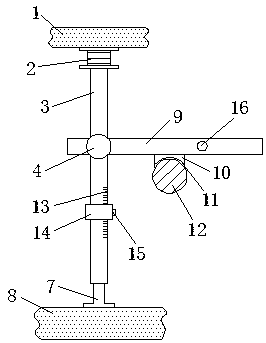

[0028] Such as figure 2 and 4 As shown, the amplitude identification device includes a limit switch 19 , a controller 20 , an alarm circuit 21 , an alarm 16 , a power supply circuit 22 , a power supply 23 and a scale scale 13 arranged on the support rod 3 . The limit switch 19 , the alarm circuit 21 , and the power circuit 22 are respectively electrically connected to the controller 20 ; the alarm 16 is electrically connected to the alarm circuit 21 , and the power supply 23 is electrically connected to the power circuit 22 . The limit switch 19 is an infrared probe 15; the infrared probe 15 is fixedly arranged on the mount 14, and the mount 14 is movably arranged on the support rod 3. The operator adjusts the position of the mounting seat 14 according to the scale scale 13 according to the laying requirements of the cable 12, so that the infrared probe 15 is in a proper position. When the cable 12 is pressed to the desired amplitude, the infrared probe 15 detects the cable...

Embodiment 3

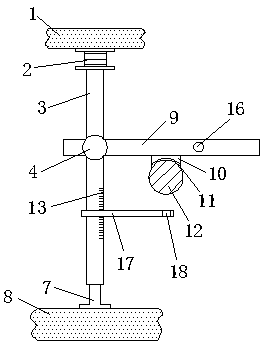

[0033] Such as Figure 4As shown, on the basis of the second embodiment, the pressure sensor 18 is used as the limit switch 19 , the support plate 17 movably connected with the support bar 3 is arranged on the support bar 3 , and the pressure sensor 18 is fixedly arranged on the support plate 17 . The operator adjusts the position of the support plate 17 according to the scale scale 13 according to the laying requirements of the cable 12, so that the pressure sensor 18 is in a proper position. When the cable 12 is pressed to the desired amplitude, the pressure sensor 18 detects the cable 12 and sends a signal to the controller 20. The controller 20 controls the alarm 16 to alarm and informs the operator that the laying amplitude has been reached, so that the operator can accurately and effectively control the cable 12. Shaped laying offset, effectively improving work efficiency.

[0034] The controller 20 can adopt the AT89C51 single-chip microcomputer, which has the characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com