Wastewater treatment zero-emission technology for chemical enterprise and park

A wastewater treatment and zero discharge technology, applied in multi-stage water treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of complex wastewater quality components, high pollutant content, low biodegradability, etc., to achieve The operation is simple and convenient, the process recovery rate is high, and the effect of reducing personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

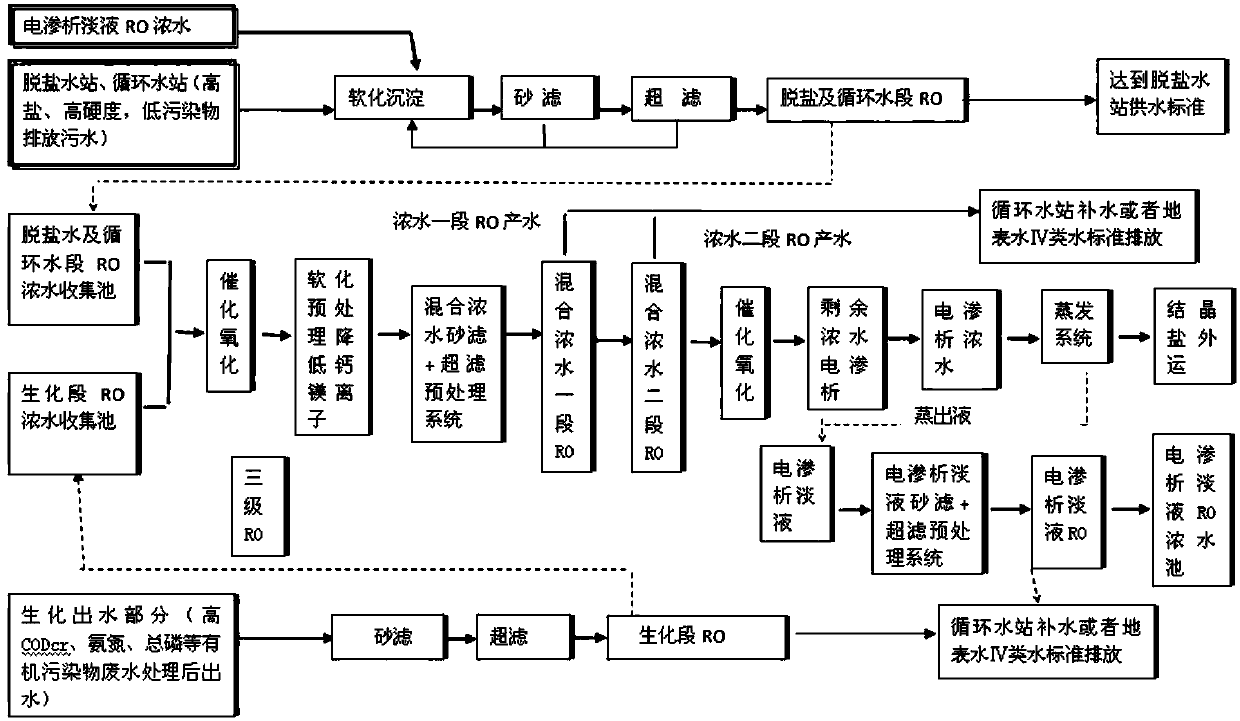

[0018] Such as figure 1 As shown, the present invention first collects the desalted water and circulating water sewage through the regulating tank, and then removes the calcium and magnesium ions and the total hardness in the water through a softening and sedimentation system, and then removes colloids, suspended particles, and color in the water through sand filtration and ultrafiltration. degree, turbidity, bacteria and macromolecular organic pollutants, and then processed by the RO system in the desalination and circulating water section. collection pool.

[0019] The waste water produced in production and life is pretreated by physicochemical and biochemical, and then collected by the regulating tank, and then the colloid, suspended particles, color, turbidity, bacteria and macromolecular organic pollutants in the water are removed by san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com