Polysiloxane-polyurethane gel material and preparation method thereof

A technology of polyurethane and polysiloxane, applied in the field of organic polymer material preparation, can solve the problems of increased number of organosilicon segments, severe phase separation, reduced surface free energy, etc., and achieves good environmental friendliness, compression Small deformation and enhanced cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

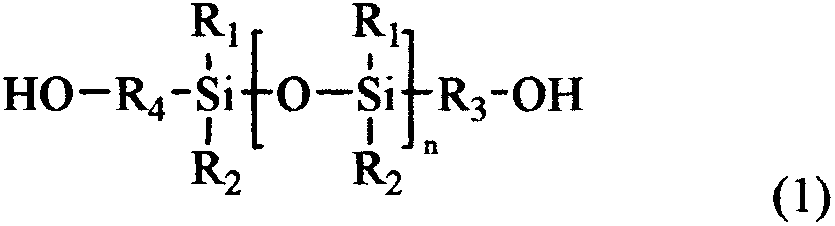

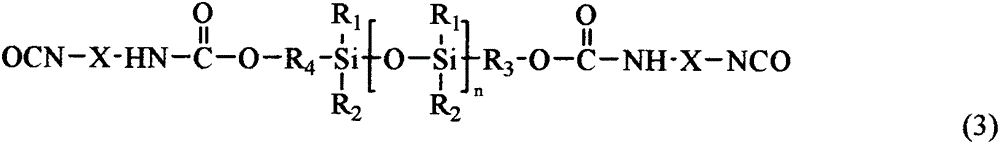

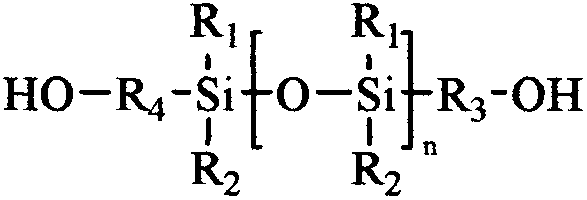

Method used

Image

Examples

Embodiment 1

[0033] Take 50 parts of polydimethylsiloxane with a molecular weight of 730, 116 parts of diphenylmethane diisocyanate, and stir at 80°C for 2 hours to prepare a semi-prepolymer A with an isocyanate content of 20%.

[0034] Get 40 parts of semi-prepolymer A, relative molecular mass is 550 parts of polyoxypropylene diols of 8000, relative molecular mass is 10 parts of polyoxypropylene tetraols of 1200, 0.8 part of dibutyltin dilaurate, bismuth isooctanoate 0.4, 1.0 parts of trimethylhydroxyethylethylenediamine, 2.2 parts of modified polysiloxane defoamer, and 3.1 parts of polyacrylate leveling agent. Stir to mix evenly, pour into shape.

[0035] The best performance was reached after 7 days, no exudation, VLRH hardness of 40, permanent compression set of 4.1%, and drop ball rebound of 22.

Embodiment 2

[0037]Take 40 parts of semi-prepolymer A prepared in Example 1, 310 parts of polyoxypropylene diols with a relative molecular mass of 6000, 20 parts of polytetrahydrofuran diols with a relative molecular mass of 2000, and polyoxypropylene diols with a relative molecular mass of 600 16 parts of triol, 1.0 parts of dibutyltin ditetradecanoate, 0.6 parts of triethylenediamine, 1.5 parts of silicone defoamer, 3 parts of molecular sieve desiccant, and 1.3 parts of polyacrylate leveling agent. Stir to mix evenly, pour into shape.

[0038] The best performance was reached after 7 days, no exudation, VLRH hardness of 33, permanent compression set of 5.1%, and drop ball rebound of 18.

Embodiment 3

[0040] Take 40 parts of polydiethylsiloxane with a molecular weight of 540, 40 parts of diphenylmethane diisocyanate, and 60 parts of toluene diisocyanate, and stir at 90°C for 2 hours to prepare a semi-prepolymer A with an isocyanate content of 25%.

[0041] Get 50 parts of semi-prepolymer A, 410 parts of polyoxypropylene diols of relative molecular mass 5000, 30 parts of polycaprolactone triols of relative molecular mass 1000, 8 parts of xylitol polyether pentaol of relative molecular mass 1000 , 1.4 parts of di(dodecylsulfide) dibutyltin, 1.0 parts of cyclohexylmethyl tertiary amine, 1.8 parts of modified polysiloxane defoamer, 2.2 parts of molecular sieve desiccant, and 1.6 parts of polyacrylate leveling agent. Stir to mix evenly, pour into shape.

[0042] The best performance was reached after 7 days, no exudation, VLRH hardness of 42, permanent compression set of 3.9%, and drop ball rebound of 28.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com