Mixed phase reinforced zirconium-based amorphous composite material and preparation method thereof

A technology for zirconium-based amorphous alloys and composite materials, which is applied in the field of hybrid phase-reinforced zirconium-based amorphous composite materials and its preparation, can solve the problems of large size, uneven distribution, low alloy plasticity, etc., and achieve high repetition rate, gas And the effect of less volatile impurities and promoting uniform precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a hybrid-phase reinforced zirconium-based amorphous composite material, which includes the following steps:

[0037] S1, according to the atomic fraction (Zr a Cu b Al c ) d Ta e Mix raw materials Zr, Cu, Al, Ta block, where a, b, c, d, e are atomic percentages, 0.46≤a=b≤0.475, 0.05≤c≤0.08; 92≤d<100, 0

[0038] In some embodiments, the raw materials Zr, Cu, Al, and Ta blocks are mechanically polished in advance to remove oxide scales to ensure the high purity of each raw material metal block. Specifically, the purity of the Zr, Cu, Al, and Ta raw materials is uniform. Greater than 99.5%.

[0039] S2. Using a vacuum electric arc furnace, the alloy raw materials are arc smelted to obtain a Zr-Ta master alloy and a Zr-Cu-Al-Ta master alloy. Specifically, the Zr block and Ta block configured according to the atomic percentage are placed in the water-cooled copper mold of the electr...

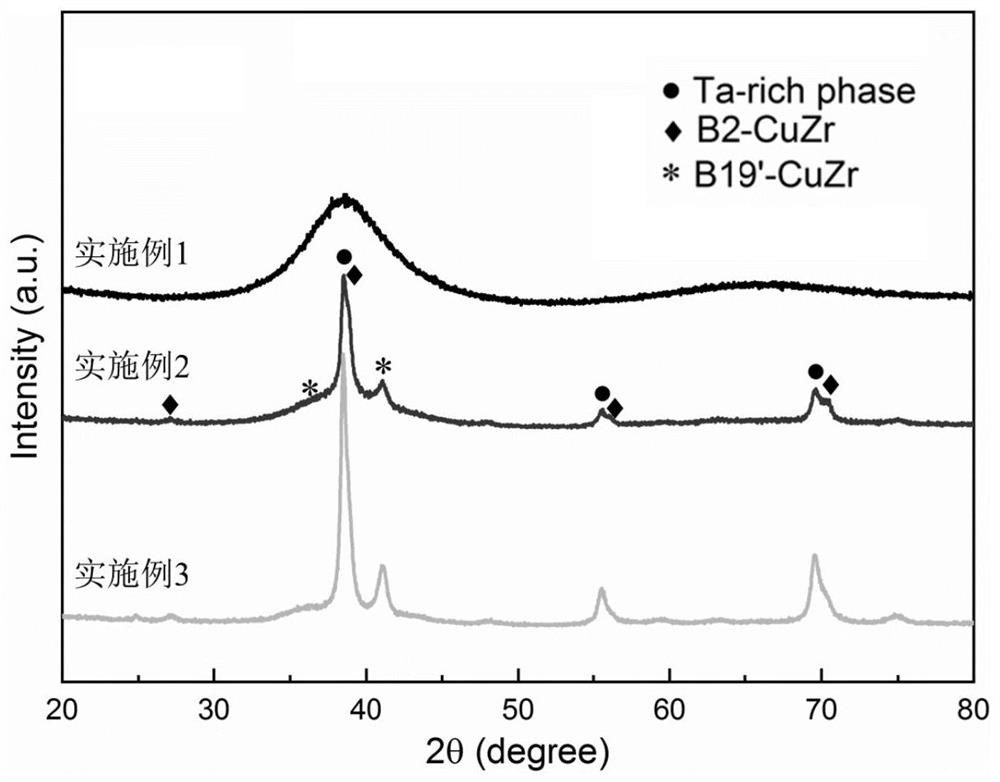

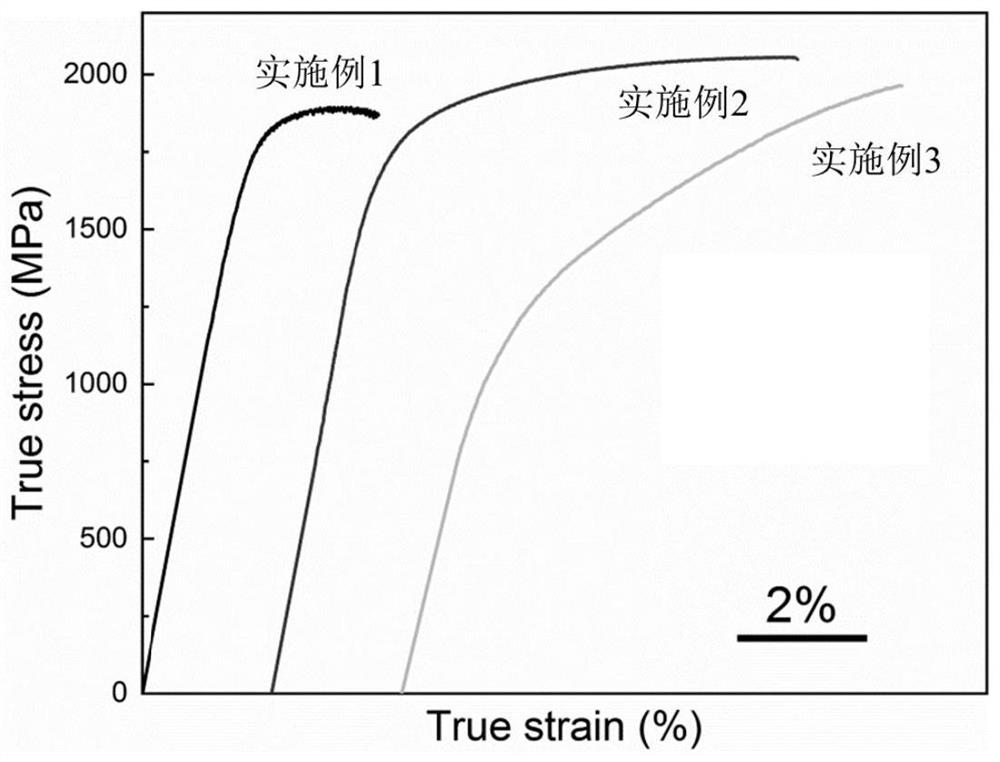

Embodiment 1

[0049] What this embodiment prepares is Zr 46 Cu 46 Al 8 The matrix alloy specifically comprises the following steps:

[0050] (1) Carry out mechanical grinding to the alloy raw material, remove scale, Zr 46 Cu 46 Al 8 The atomic percentage of the base alloy is converted into a mass percentage, and the corresponding Zr block, Cu block and Al block are weighed and configured according to a total mass of about 30 g.

[0051] (2) Put the configured Zr block, Cu block and Al block into the water-cooled copper mold of the vacuum melting furnace, and vacuum the furnace body to 3.0×10 -3 Pa, pass in argon gas with a purity of 99.999% to a relative pressure of -0.05 MPa, conduct arc melting on the raw materials, keep the melting temperature at 1000 ° C ~ 2000 ° C, and stop melting after fully melting for 3 minutes, and use the turning rod to smelt the alloy Turn the ingot over and repeat the smelting for a total of 4 times to obtain Zr 46 Cu 46 Al 8 master alloy.

[0052] (3...

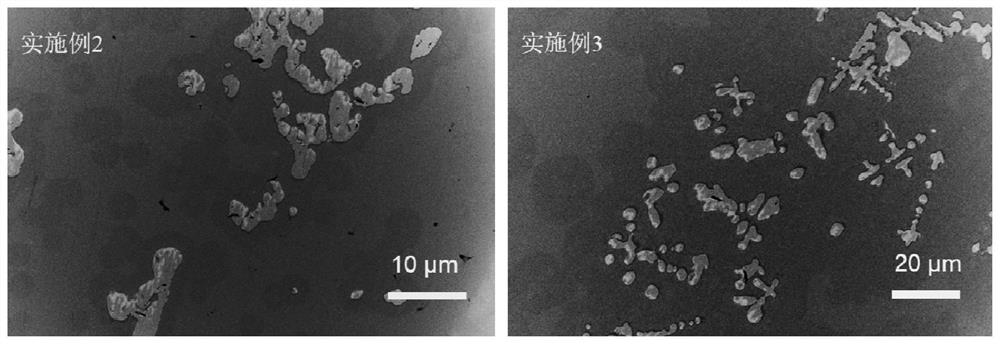

Embodiment 2

[0055] What this embodiment prepares is (Zr 0.46 Cu 0.46 Al 0.08 ) 95 Ta 5 Composite materials specifically include the following steps:

[0056] (1) Carry out mechanical grinding to the alloy raw material, remove scale, and (Zr 0.46 Cu 0.46 Al 0.08 ) 95 Ta 5 The atomic percentage of the alloy is converted into a mass percentage, and the corresponding Zr block, Cu block, Al block and Ta block are prepared by weighing according to a total mass of about 30 g.

[0057](2) Put the configured Zr block and Ta block into the water-cooled copper mold of the vacuum melting furnace, and vacuum the furnace body to 3.0×10 -3 Pa, pass in argon gas with a purity of 99.999% to a relative pressure of -0.05 MPa, conduct arc melting on the raw materials, keep the melting temperature at 3000 ° C ~ 3500 ° C, and stop the melting after fully melting for 3 minutes. Turn the ingot over and repeat the smelting for a total of 4 times to obtain the Zr-Ta master alloy;

[0058] Put the Zr-Ta ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com